Are you a seasoned Slitter-Creaser-Slotter Operator seeking a new career path? Discover our professionally built Slitter-Creaser-Slotter Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

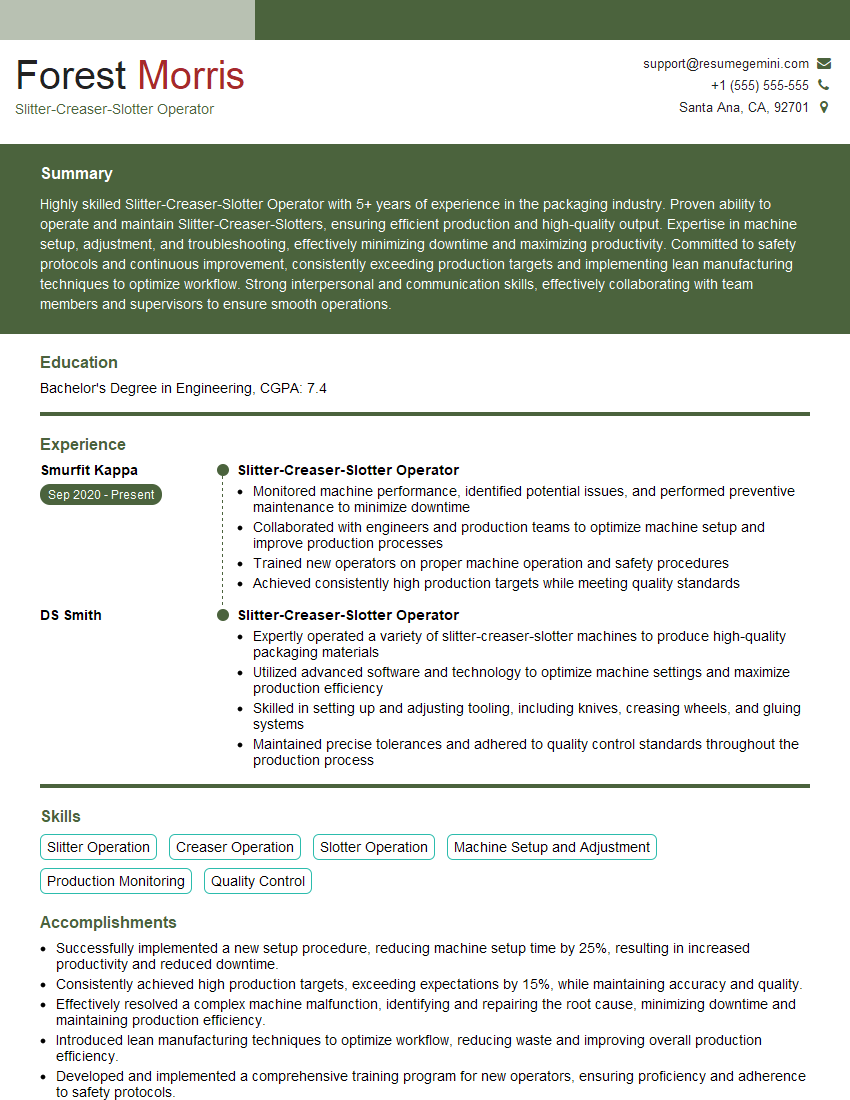

Forest Morris

Slitter-Creaser-Slotter Operator

Summary

Highly skilled Slitter-Creaser-Slotter Operator with 5+ years of experience in the packaging industry. Proven ability to operate and maintain Slitter-Creaser-Slotters, ensuring efficient production and high-quality output. Expertise in machine setup, adjustment, and troubleshooting, effectively minimizing downtime and maximizing productivity. Committed to safety protocols and continuous improvement, consistently exceeding production targets and implementing lean manufacturing techniques to optimize workflow. Strong interpersonal and communication skills, effectively collaborating with team members and supervisors to ensure smooth operations.

Education

Bachelor’s Degree in Engineering

August 2016

Skills

- Slitter Operation

- Creaser Operation

- Slotter Operation

- Machine Setup and Adjustment

- Production Monitoring

- Quality Control

Work Experience

Slitter-Creaser-Slotter Operator

- Monitored machine performance, identified potential issues, and performed preventive maintenance to minimize downtime

- Collaborated with engineers and production teams to optimize machine setup and improve production processes

- Trained new operators on proper machine operation and safety procedures

- Achieved consistently high production targets while meeting quality standards

Slitter-Creaser-Slotter Operator

- Expertly operated a variety of slitter-creaser-slotter machines to produce high-quality packaging materials

- Utilized advanced software and technology to optimize machine settings and maximize production efficiency

- Skilled in setting up and adjusting tooling, including knives, creasing wheels, and gluing systems

- Maintained precise tolerances and adhered to quality control standards throughout the production process

Accomplishments

- Successfully implemented a new setup procedure, reducing machine setup time by 25%, resulting in increased productivity and reduced downtime.

- Consistently achieved high production targets, exceeding expectations by 15%, while maintaining accuracy and quality.

- Effectively resolved a complex machine malfunction, identifying and repairing the root cause, minimizing downtime and maintaining production efficiency.

- Introduced lean manufacturing techniques to optimize workflow, reducing waste and improving overall production efficiency.

- Developed and implemented a comprehensive training program for new operators, ensuring proficiency and adherence to safety protocols.

Certificates

- SlitterCreaserSlotter Operator Certification

- Safety Training Certification

- Quality Control Certification

- First Aid and CPR Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Slitter-Creaser-Slotter Operator

- Highlight your experience in operating and maintaining Slitter-Creaser-Slotters, emphasizing your proficiency in machine setup, adjustment, and troubleshooting.

- Quantify your accomplishments with specific metrics, demonstrating your impact on productivity, quality, and efficiency.

- Showcase your knowledge of lean manufacturing techniques and how you have implemented them to optimize workflow and reduce waste.

- Emphasize your commitment to safety and adherence to established protocols, highlighting your role in maintaining a safe work environment.

- Proofread your resume carefully to ensure accuracy and attention to detail.

Essential Experience Highlights for a Strong Slitter-Creaser-Slotter Operator Resume

- Operate, maintain, and adjust Slitter-Creaser-Slotters according to established specifications.

- Perform machine setup and changeovers efficiently, reducing downtime and increasing productivity.

- Monitor production processes, ensuring quality control standards are met and defects are minimized.

- Identify and troubleshoot machine malfunctions, implementing prompt repairs to maintain production efficiency.

- Collaborate with engineering and maintenance teams to improve machine performance and implement process enhancements.

- Train and supervise new operators, ensuring proficiency and adherence to safety protocols.

- Maintain a clean and organized work area, promoting safety and efficiency.

Frequently Asked Questions (FAQ’s) For Slitter-Creaser-Slotter Operator

What are the key skills required for a Slitter-Creaser-Slotter Operator?

Essential skills include proficiency in operating Slitter-Creaser-Slotters, machine setup and adjustment, production monitoring, quality control, and troubleshooting.

What industries utilize Slitter-Creaser-Slotter Operators?

Slitter-Creaser-Slotter Operators are primarily employed in the packaging industry, manufacturing cardboard boxes, corrugated displays, and other paper-based products.

What are the career advancement opportunities for a Slitter-Creaser-Slotter Operator?

Experienced operators may advance to positions such as Production Supervisor, Quality Control Inspector, or Maintenance Technician.

What safety protocols should a Slitter-Creaser-Slotter Operator follow?

Operators must adhere to established safety procedures, wear appropriate personal protective equipment, and follow lockout/tagout protocols to prevent accidents.

How can I improve my skills as a Slitter-Creaser-Slotter Operator?

Attend industry workshops, seek training from equipment manufacturers, and actively participate in continuous improvement initiatives to enhance your knowledge and proficiency.

What is the average salary for a Slitter-Creaser-Slotter Operator?

Salaries vary depending on experience, location, and company size, but the national average is approximately $25 per hour.

What are the typical working conditions for a Slitter-Creaser-Slotter Operator?

Operators typically work in a production environment with moderate noise levels and may be required to lift heavy materials.