Are you a seasoned Swedger seeking a new career path? Discover our professionally built Swedger Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

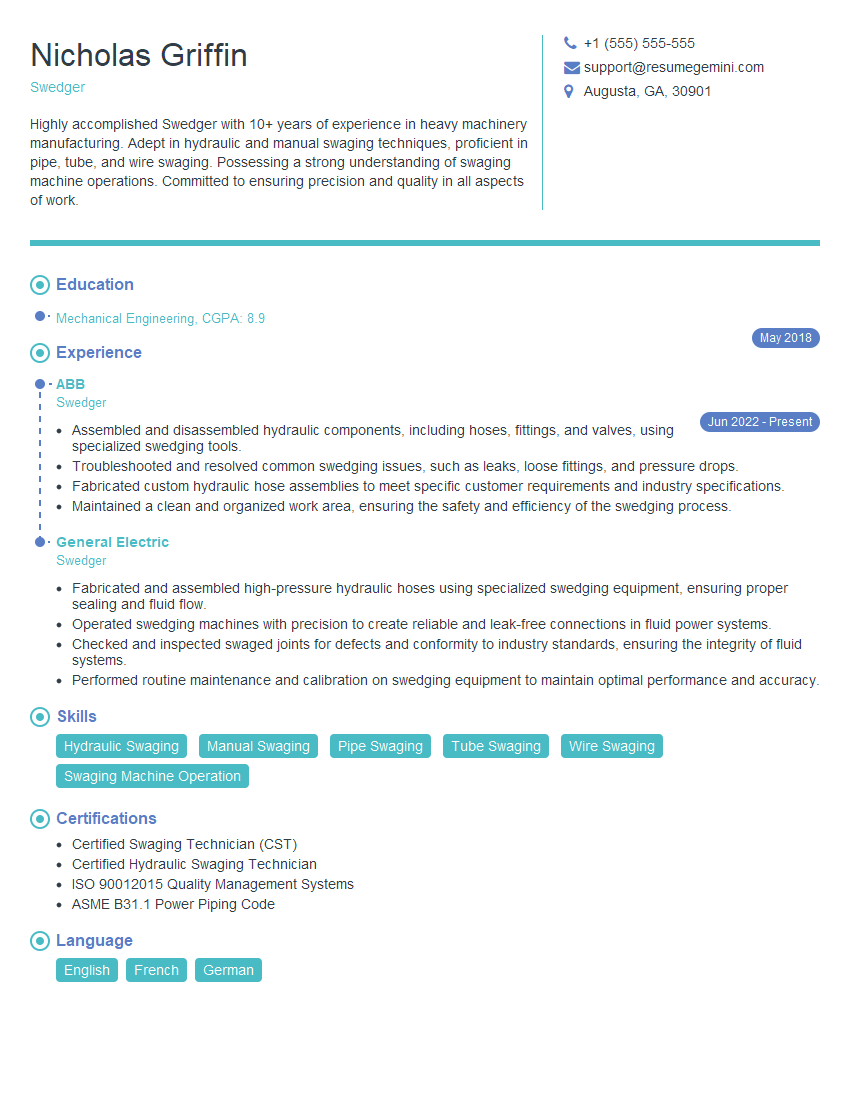

Nicholas Griffin

Swedger

Summary

Highly accomplished Swedger with 10+ years of experience in heavy machinery manufacturing. Adept in hydraulic and manual swaging techniques, proficient in pipe, tube, and wire swaging. Possessing a strong understanding of swaging machine operations. Committed to ensuring precision and quality in all aspects of work.

Education

Mechanical Engineering

May 2018

Skills

- Hydraulic Swaging

- Manual Swaging

- Pipe Swaging

- Tube Swaging

- Wire Swaging

- Swaging Machine Operation

Work Experience

Swedger

- Assembled and disassembled hydraulic components, including hoses, fittings, and valves, using specialized swedging tools.

- Troubleshooted and resolved common swedging issues, such as leaks, loose fittings, and pressure drops.

- Fabricated custom hydraulic hose assemblies to meet specific customer requirements and industry specifications.

- Maintained a clean and organized work area, ensuring the safety and efficiency of the swedging process.

Swedger

- Fabricated and assembled high-pressure hydraulic hoses using specialized swedging equipment, ensuring proper sealing and fluid flow.

- Operated swedging machines with precision to create reliable and leak-free connections in fluid power systems.

- Checked and inspected swaged joints for defects and conformity to industry standards, ensuring the integrity of fluid systems.

- Performed routine maintenance and calibration on swedging equipment to maintain optimal performance and accuracy.

Certificates

- Certified Swaging Technician (CST)

- Certified Hydraulic Swaging Technician

- ISO 90012015 Quality Management Systems

- ASME B31.1 Power Piping Code

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Swedger

- Showcase your expertise in hydraulic and manual swaging techniques, highlighting your proficiency in producing precision parts.

- Quantify your accomplishments by providing specific examples of how you have improved efficiency, reduced errors, or implemented innovative solutions.

- Emphasize your ability to operate and maintain swaging machines, demonstrating your technical skills and attention to detail.

- Highlight your commitment to quality assurance by describing your experience in inspecting and measuring swaged parts to ensure compliance with specifications.

- Mention your teamwork and communication skills, emphasizing your ability to collaborate effectively with production team members to achieve project goals.

Essential Experience Highlights for a Strong Swedger Resume

- Operate and maintain hydraulic and manual swaging machines to produce precision parts for various industrial applications.

- Perform setup and calibration of swaging machines to meet specific production requirements.

- Inspect and measure swaged parts to ensure they conform to the specified dimensions and tolerances.

- Troubleshoot and resolve any mechanical issues that may arise during the swaging process.

- Handle and transport heavy materials safely and efficiently while adhering to safety regulations.

- Maintain a clean and organized workspace to ensure optimal productivity and minimize risks.

- Collaborate with production team members to achieve production goals and quality standards.

Frequently Asked Questions (FAQ’s) For Swedger

What is the primary role of a Swedger?

Swedgers are responsible for operating and maintaining hydraulic and manual swaging machines to produce precision parts for various industrial applications, ensuring adherence to specified dimensions and tolerances.

What are the key skills required to excel as a Swedger?

Essential skills for Swedgers include proficiency in hydraulic and manual swaging techniques, knowledge of pipe, tube, and wire swaging, expertise in swaging machine operation, and a commitment to precision and quality.

What are the career prospects for Swedgers?

Skilled Swedgers with experience in heavy machinery manufacturing can find employment in various industries, including automotive, aerospace, construction, and oil and gas.

How can I enhance my resume as a Swedger?

To strengthen your resume, highlight your expertise in swaging techniques, quantify your accomplishments, demonstrate your proficiency in operating and maintaining swaging machines, emphasize your commitment to quality assurance, and showcase your teamwork and communication skills.

What are the common challenges faced by Swedgers?

Swedgers may encounter challenges such as ensuring precision and accuracy in swaging operations, maintaining a safe and efficient work environment, and troubleshooting mechanical issues with swaging machines.

How can I stay updated on the latest industry trends as a Swedger?

To remain informed about industry advancements, Swedgers can attend industry events, read technical journals, and participate in professional development opportunities.