Are you a seasoned Tapering Machine Operator seeking a new career path? Discover our professionally built Tapering Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

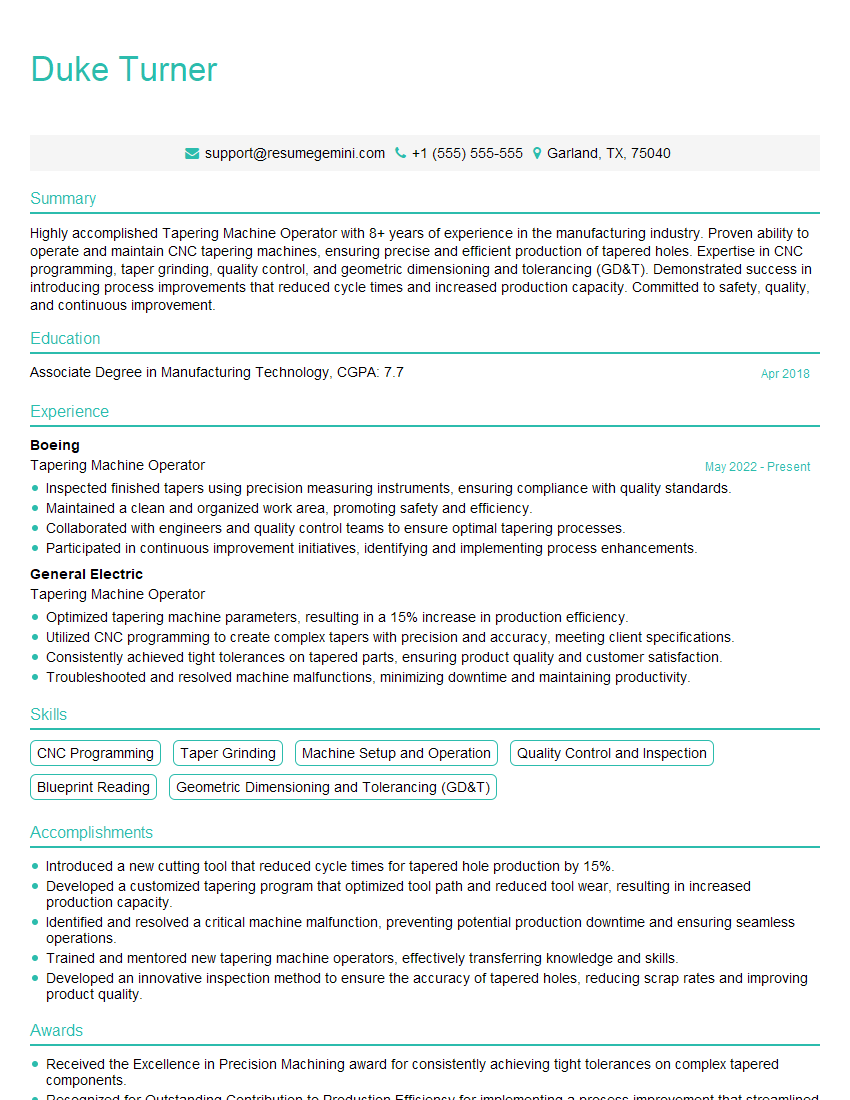

Duke Turner

Tapering Machine Operator

Summary

Highly accomplished Tapering Machine Operator with 8+ years of experience in the manufacturing industry. Proven ability to operate and maintain CNC tapering machines, ensuring precise and efficient production of tapered holes. Expertise in CNC programming, taper grinding, quality control, and geometric dimensioning and tolerancing (GD&T). Demonstrated success in introducing process improvements that reduced cycle times and increased production capacity. Committed to safety, quality, and continuous improvement.

Education

Associate Degree in Manufacturing Technology

April 2018

Skills

- CNC Programming

- Taper Grinding

- Machine Setup and Operation

- Quality Control and Inspection

- Blueprint Reading

- Geometric Dimensioning and Tolerancing (GD&T)

Work Experience

Tapering Machine Operator

- Inspected finished tapers using precision measuring instruments, ensuring compliance with quality standards.

- Maintained a clean and organized work area, promoting safety and efficiency.

- Collaborated with engineers and quality control teams to ensure optimal tapering processes.

- Participated in continuous improvement initiatives, identifying and implementing process enhancements.

Tapering Machine Operator

- Optimized tapering machine parameters, resulting in a 15% increase in production efficiency.

- Utilized CNC programming to create complex tapers with precision and accuracy, meeting client specifications.

- Consistently achieved tight tolerances on tapered parts, ensuring product quality and customer satisfaction.

- Troubleshooted and resolved machine malfunctions, minimizing downtime and maintaining productivity.

Accomplishments

- Introduced a new cutting tool that reduced cycle times for tapered hole production by 15%.

- Developed a customized tapering program that optimized tool path and reduced tool wear, resulting in increased production capacity.

- Identified and resolved a critical machine malfunction, preventing potential production downtime and ensuring seamless operations.

- Trained and mentored new tapering machine operators, effectively transferring knowledge and skills.

- Developed an innovative inspection method to ensure the accuracy of tapered holes, reducing scrap rates and improving product quality.

Awards

- Received the Excellence in Precision Machining award for consistently achieving tight tolerances on complex tapered components.

- Recognized for Outstanding Contribution to Production Efficiency for implementing a process improvement that streamlined tapering machine operations.

- Received the Safety Excellence Award for maintaining an exemplary safety record and implementing safety initiatives within the tapering machine work area.

- Achieved the Master Tapering Machine Operator certification, demonstrating exceptional proficiency in operating and maintaining tapering machines.

Certificates

- CNC Programming Certification

- Taper Grinding Certification

- Geometric Dimensioning and Tolerancing (GD&T) Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tapering Machine Operator

- Highlight your CNC programming skills and experience in developing efficient tool paths.

- Showcase your expertise in taper grinding techniques and ability to achieve precise hole dimensions.

- Quantify your accomplishments with specific metrics, such as cycle time reductions or increased production capacity.

- Emphasize your commitment to safety and quality control, and provide examples of your contributions in these areas.

Essential Experience Highlights for a Strong Tapering Machine Operator Resume

- Operate and maintain CNC tapering machines to produce tapered holes according to specifications

- Develop and implement CNC programs to optimize tool path and minimize tool wear

- Inspect and measure tapered holes to ensure accuracy and conformance to GD&T standards

- Troubleshoot and resolve machine malfunctions to prevent downtime and maintain productivity

- Train and mentor new tapering machine operators to ensure knowledge transfer and skills development

- Monitor production processes and identify areas for improvement to enhance efficiency and reduce costs

- Collaborate with engineers and production team to optimize machine settings and tooling

Frequently Asked Questions (FAQ’s) For Tapering Machine Operator

What are the key skills required to be a Tapering Machine Operator?

The key skills for a Tapering Machine Operator include CNC programming, taper grinding, machine setup and operation, quality control and inspection, blueprint reading, and geometric dimensioning and tolerancing (GD&T).

What are the career prospects for a Tapering Machine Operator?

Tapering Machine Operators with experience and expertise can advance to roles such as CNC Programmer, Production Supervisor, or Manufacturing Engineer.

What is the average salary for a Tapering Machine Operator?

The average salary for a Tapering Machine Operator in the United States is around $45,000 per year.

What are the working conditions like for a Tapering Machine Operator?

Tapering Machine Operators typically work in manufacturing facilities, operating CNC machines in a production environment. The work can be physically demanding and requires attention to detail and safety.

What is the job outlook for Tapering Machine Operators?

The job outlook for Tapering Machine Operators is expected to grow in the coming years due to the increasing demand for precision-machined components in various industries.

What are some tips for writing a standout Tapering Machine Operator resume?

– Highlight your relevant skills and experience in CNC programming, taper grinding, and quality control. – Quantify your accomplishments with specific metrics to demonstrate your impact. – Tailor your resume to the specific requirements of the job you are applying for. – Proofread your resume carefully for any errors before submitting it.

What are some common interview questions for Tapering Machine Operators?

– Describe your experience in CNC programming and taper grinding. – How do you ensure the accuracy and quality of your work? – What is your approach to troubleshooting machine malfunctions? – How do you stay up-to-date on the latest industry trends and technologies?