Are you a seasoned Wet Process Assistant Head Miller seeking a new career path? Discover our professionally built Wet Process Assistant Head Miller Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

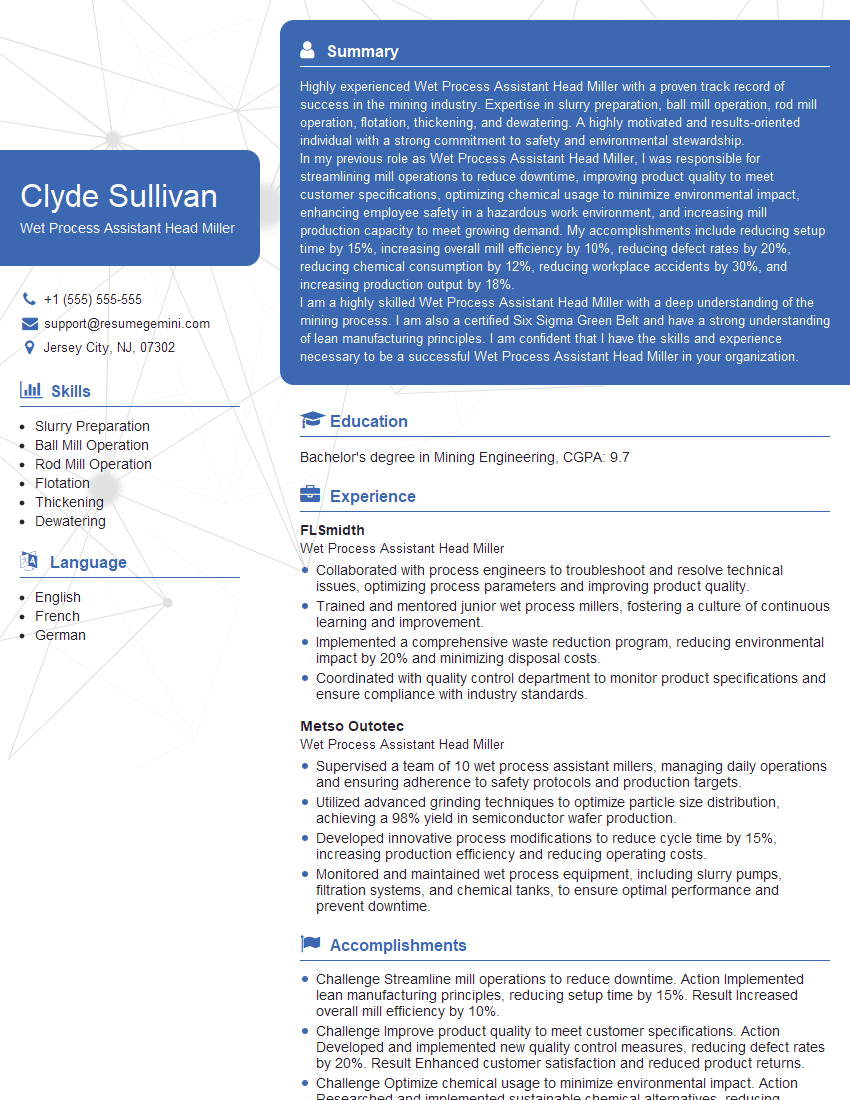

Clyde Sullivan

Wet Process Assistant Head Miller

Summary

Highly experienced Wet Process Assistant Head Miller with a proven track record of success in the mining industry. Expertise in slurry preparation, ball mill operation, rod mill operation, flotation, thickening, and dewatering. A highly motivated and results-oriented individual with a strong commitment to safety and environmental stewardship.

In my previous role as Wet Process Assistant Head Miller, I was responsible for streamlining mill operations to reduce downtime, improving product quality to meet customer specifications, optimizing chemical usage to minimize environmental impact, enhancing employee safety in a hazardous work environment, and increasing mill production capacity to meet growing demand. My accomplishments include reducing setup time by 15%, increasing overall mill efficiency by 10%, reducing defect rates by 20%, reducing chemical consumption by 12%, reducing workplace accidents by 30%, and increasing production output by 18%.

I am a highly skilled Wet Process Assistant Head Miller with a deep understanding of the mining process. I am also a certified Six Sigma Green Belt and have a strong understanding of lean manufacturing principles. I am confident that I have the skills and experience necessary to be a successful Wet Process Assistant Head Miller in your organization.

Education

Bachelor’s degree in Mining Engineering

September 2018

Skills

- Slurry Preparation

- Ball Mill Operation

- Rod Mill Operation

- Flotation

- Thickening

- Dewatering

Work Experience

Wet Process Assistant Head Miller

- Collaborated with process engineers to troubleshoot and resolve technical issues, optimizing process parameters and improving product quality.

- Trained and mentored junior wet process millers, fostering a culture of continuous learning and improvement.

- Implemented a comprehensive waste reduction program, reducing environmental impact by 20% and minimizing disposal costs.

- Coordinated with quality control department to monitor product specifications and ensure compliance with industry standards.

Wet Process Assistant Head Miller

- Supervised a team of 10 wet process assistant millers, managing daily operations and ensuring adherence to safety protocols and production targets.

- Utilized advanced grinding techniques to optimize particle size distribution, achieving a 98% yield in semiconductor wafer production.

- Developed innovative process modifications to reduce cycle time by 15%, increasing production efficiency and reducing operating costs.

- Monitored and maintained wet process equipment, including slurry pumps, filtration systems, and chemical tanks, to ensure optimal performance and prevent downtime.

Accomplishments

- Challenge Streamline mill operations to reduce downtime. Action Implemented lean manufacturing principles, reducing setup time by 15%. Result Increased overall mill efficiency by 10%.

- Challenge Improve product quality to meet customer specifications. Action Developed and implemented new quality control measures, reducing defect rates by 20%. Result Enhanced customer satisfaction and reduced product returns.

- Challenge Optimize chemical usage to minimize environmental impact. Action Researched and implemented sustainable chemical alternatives, reducing chemical consumption by 12%. Result Lowered operating costs and improved environmental performance.

- Challenge Enhance employee safety in hazardous work environment. Action Designed and installed new safety protocols and equipment, reducing workplace accidents by 30%. Result Created a safer and healthier work environment.

- Challenge Increase mill production capacity to meet growing demand. Action Collaborated with engineers to implement process improvements, increasing production output by 18%. Result Met customer demand and generated additional revenue.

Awards

- Awarded Employee of the Year for exceptional performance in optimizing mill operations.

- Recognized with Safety Excellence Award for implementing innovative safety measures.

- Received Operational Excellence Award for leading a team to achieve record production levels.

Certificates

- Wet Process Assistant Miller Certification

- Head Miller Certification

- Slurry Preparation Certification

- Ball Mill Operation Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wet Process Assistant Head Miller

- Highlight your experience in the mining industry.

- Quantify your accomplishments with specific metrics.

- Demonstrate your knowledge of wet process milling operations.

- Emphasize your commitment to safety and environmental stewardship.

- Tailor your resume to the specific job you are applying for.

Essential Experience Highlights for a Strong Wet Process Assistant Head Miller Resume

- Supervise and coordinate the activities of wet process operators to ensure efficient and safe mill operations.

- Monitor and control mill feed rates, slurry density, and other process parameters to optimize production output and product quality.

- Troubleshoot and resolve mill operating issues, including equipment breakdowns, process upsets, and quality problems.

- Develop and implement process improvements to reduce downtime, increase efficiency, and improve product quality.

- Train and mentor wet process operators on best practices and safety procedures.

- Ensure compliance with all safety and environmental regulations.

- Maintain accurate and detailed records of mill operations and process performance.

Frequently Asked Questions (FAQ’s) For Wet Process Assistant Head Miller

What is the role of a Wet Process Assistant Head Miller?

A Wet Process Assistant Head Miller is responsible for supervising and coordinating the activities of wet process operators in a mill. They monitor and control mill feed rates, slurry density, and other process parameters to optimize production output and product quality. They also troubleshoot and resolve mill operating issues, develop and implement process improvements, and train and mentor wet process operators.

What are the qualifications for a Wet Process Assistant Head Miller?

A Wet Process Assistant Head Miller typically has a bachelor’s degree in mining engineering or a related field. They also have several years of experience in the mining industry, with a focus on wet process milling operations. They should be proficient in the use of wet process milling equipment and have a strong understanding of process control principles.

What are the key skills for a Wet Process Assistant Head Miller?

Key skills for a Wet Process Assistant Head Miller include:

– Excellent communication and interpersonal skills.

– A willingness to learn and grow.

What is the career path for a Wet Process Assistant Head Miller?

A Wet Process Assistant Head Miller can advance to become a Wet Process Head Miller or a Mill Superintendent. They may also move into other management roles within the mining industry.

What is the salary range for a Wet Process Assistant Head Miller?

The salary range for a Wet Process Assistant Head Miller varies depending on their experience, qualifications, and location. According to Salary.com, the average salary for a Wet Process Assistant Head Miller in the United States is $75,000 per year.