Are you a seasoned Wire Rope Sling Maker seeking a new career path? Discover our professionally built Wire Rope Sling Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

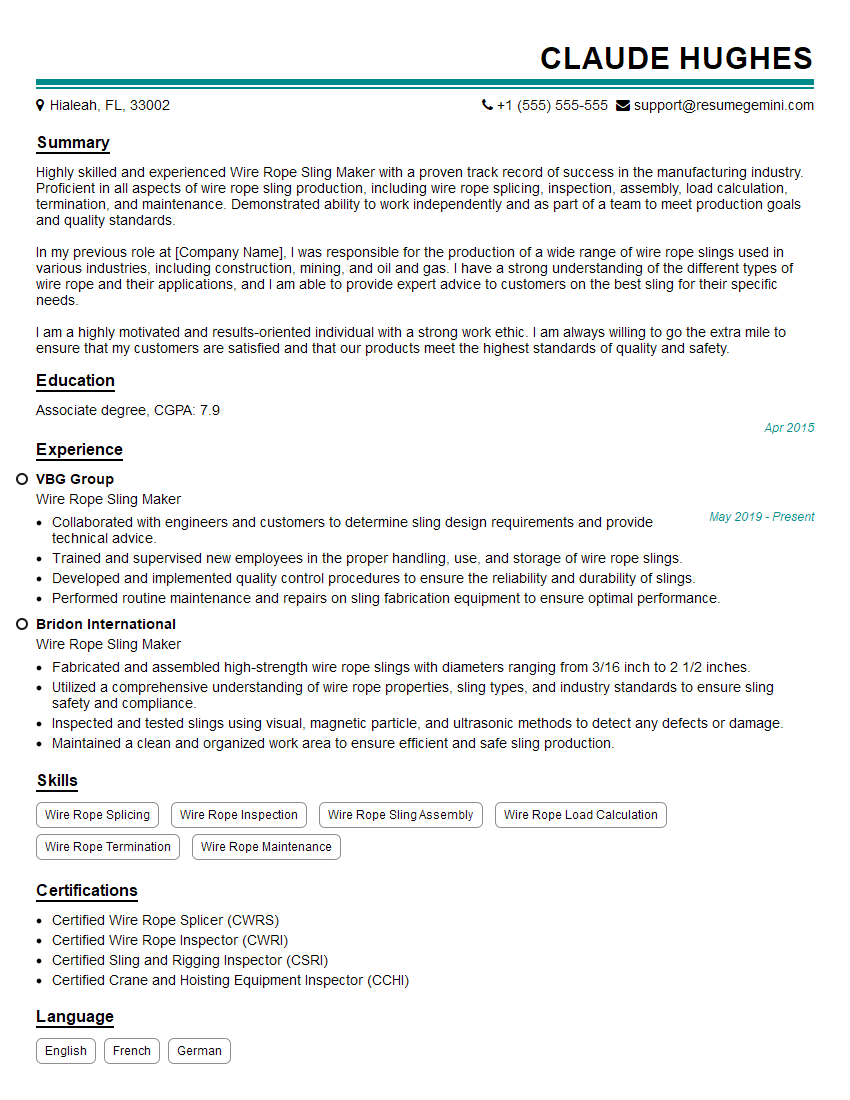

Claude Hughes

Wire Rope Sling Maker

Summary

Highly skilled and experienced Wire Rope Sling Maker with a proven track record of success in the manufacturing industry. Proficient in all aspects of wire rope sling production, including wire rope splicing, inspection, assembly, load calculation, termination, and maintenance. Demonstrated ability to work independently and as part of a team to meet production goals and quality standards.

In my previous role at [Company Name], I was responsible for the production of a wide range of wire rope slings used in various industries, including construction, mining, and oil and gas. I have a strong understanding of the different types of wire rope and their applications, and I am able to provide expert advice to customers on the best sling for their specific needs.

I am a highly motivated and results-oriented individual with a strong work ethic. I am always willing to go the extra mile to ensure that my customers are satisfied and that our products meet the highest standards of quality and safety.

Education

Associate degree

April 2015

Skills

- Wire Rope Splicing

- Wire Rope Inspection

- Wire Rope Sling Assembly

- Wire Rope Load Calculation

- Wire Rope Termination

- Wire Rope Maintenance

Work Experience

Wire Rope Sling Maker

- Collaborated with engineers and customers to determine sling design requirements and provide technical advice.

- Trained and supervised new employees in the proper handling, use, and storage of wire rope slings.

- Developed and implemented quality control procedures to ensure the reliability and durability of slings.

- Performed routine maintenance and repairs on sling fabrication equipment to ensure optimal performance.

Wire Rope Sling Maker

- Fabricated and assembled high-strength wire rope slings with diameters ranging from 3/16 inch to 2 1/2 inches.

- Utilized a comprehensive understanding of wire rope properties, sling types, and industry standards to ensure sling safety and compliance.

- Inspected and tested slings using visual, magnetic particle, and ultrasonic methods to detect any defects or damage.

- Maintained a clean and organized work area to ensure efficient and safe sling production.

Certificates

- Certified Wire Rope Splicer (CWRS)

- Certified Wire Rope Inspector (CWRI)

- Certified Sling and Rigging Inspector (CSRI)

- Certified Crane and Hoisting Equipment Inspector (CCHI)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wire Rope Sling Maker

- Highlight your skills and experience in wire rope splicing, inspection, assembly, load calculation, termination, and maintenance.

- Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your impact on the company.

- Use keywords throughout your resume, but make sure to do so in a natural and organic way.

- Proofread your resume carefully before submitting it to ensure that there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Wire Rope Sling Maker Resume

- Splice wire rope using a variety of techniques, including hand splicing, mechanical splicing, and socketing.

- Inspect wire rope slings for damage and wear, and make repairs as necessary.

- Assemble wire rope slings according to customer specifications, including length, diameter, and fittings.

- Calculate the load capacity of wire rope slings based on the type of rope, construction, and fittings used.

- Terminate wire rope slings using a variety of methods, including swaging, socketing, and hand splicing.

- Maintain wire rope slings in good working condition through regular inspection and maintenance.

Frequently Asked Questions (FAQ’s) For Wire Rope Sling Maker

What is a wire rope sling?

A wire rope sling is a type of lifting device that is used to lift and move heavy objects. It is made of a series of wire ropes that are spliced together to form a loop. The loop is then fitted with a variety of fittings, such as hooks, shackles, and rings, which allow it to be attached to the object being lifted.

What are the different types of wire rope slings?

There are a variety of different types of wire rope slings, each with its own unique properties and applications. The most common types of wire rope slings include single leg slings, double leg slings, and multi-leg slings.

What are the factors to consider when choosing a wire rope sling?

When choosing a wire rope sling, there are a number of factors to consider, including the weight of the object being lifted, the length of the lift, the type of environment in which the sling will be used, and the budget.

How do I inspect a wire rope sling?

Wire rope slings should be inspected regularly for damage and wear. The inspection should include a visual examination of the rope for any signs of damage, such as broken wires, kinks, or rust. The inspector should also check the fittings for any signs of damage or wear.

How do I store wire rope?

Wire rope should be stored in a dry, well-ventilated area. The rope should be coiled or spooled to prevent it from becoming tangled or kinked.

What are the safety precautions to consider when using wire rope?

There are a number of safety precautions to consider when using wire rope, including: Never exceed the rated load capacity of the sling. Never use a sling that is damaged or worn. Never use a sling that has been kinked or twisted. Always inspect the sling before each use.