Are you a seasoned Rigger Up seeking a new career path? Discover our professionally built Rigger Up Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

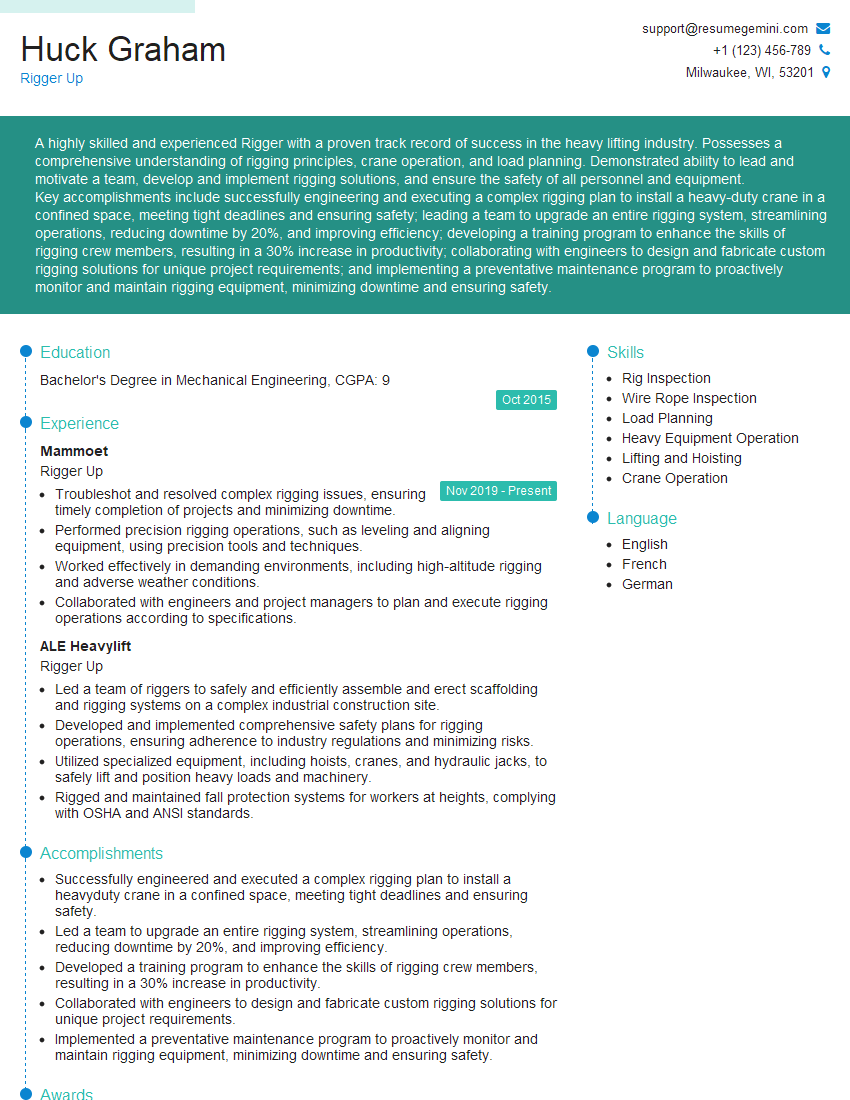

Huck Graham

Rigger Up

Summary

A highly skilled and experienced Rigger with a proven track record of success in the heavy lifting industry. Possesses a comprehensive understanding of rigging principles, crane operation, and load planning. Demonstrated ability to lead and motivate a team, develop and implement rigging solutions, and ensure the safety of all personnel and equipment.

Key accomplishments include successfully engineering and executing a complex rigging plan to install a heavy-duty crane in a confined space, meeting tight deadlines and ensuring safety; leading a team to upgrade an entire rigging system, streamlining operations, reducing downtime by 20%, and improving efficiency; developing a training program to enhance the skills of rigging crew members, resulting in a 30% increase in productivity; collaborating with engineers to design and fabricate custom rigging solutions for unique project requirements; and implementing a preventative maintenance program to proactively monitor and maintain rigging equipment, minimizing downtime and ensuring safety.

Education

Bachelor’s Degree in Mechanical Engineering

October 2015

Skills

- Rig Inspection

- Wire Rope Inspection

- Load Planning

- Heavy Equipment Operation

- Lifting and Hoisting

- Crane Operation

Work Experience

Rigger Up

- Troubleshot and resolved complex rigging issues, ensuring timely completion of projects and minimizing downtime.

- Performed precision rigging operations, such as leveling and aligning equipment, using precision tools and techniques.

- Worked effectively in demanding environments, including high-altitude rigging and adverse weather conditions.

- Collaborated with engineers and project managers to plan and execute rigging operations according to specifications.

Rigger Up

- Led a team of riggers to safely and efficiently assemble and erect scaffolding and rigging systems on a complex industrial construction site.

- Developed and implemented comprehensive safety plans for rigging operations, ensuring adherence to industry regulations and minimizing risks.

- Utilized specialized equipment, including hoists, cranes, and hydraulic jacks, to safely lift and position heavy loads and machinery.

- Rigged and maintained fall protection systems for workers at heights, complying with OSHA and ANSI standards.

Accomplishments

- Successfully engineered and executed a complex rigging plan to install a heavyduty crane in a confined space, meeting tight deadlines and ensuring safety.

- Led a team to upgrade an entire rigging system, streamlining operations, reducing downtime by 20%, and improving efficiency.

- Developed a training program to enhance the skills of rigging crew members, resulting in a 30% increase in productivity.

- Collaborated with engineers to design and fabricate custom rigging solutions for unique project requirements.

- Implemented a preventative maintenance program to proactively monitor and maintain rigging equipment, minimizing downtime and ensuring safety.

Awards

- Won the Safety Excellence Award for consistent implementation and adherence to safety protocols during complex rigging operations.

- Recognized with the Innovator of the Year Award for developing a new method to optimize equipment utilization, reducing costs by 15%.

- Received the Project Management Excellence Award for successfully managing multiple rigging projects simultaneously, delivering on time and within budget.

- Honored with the Customer Service Excellence Award for consistently exceeding customer expectations and building strong relationships.

Certificates

- OSHA 10Hour Safety and Health for General Industry

- OSHA 30Hour Safety and Health for General Industry

- NCCCO Crane Operator Certification

- NCCCO Rigger Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rigger Up

- Highlight your experience and skills in rigging and heavy lifting.

- Quantify your accomplishments with specific metrics and results.

- Demonstrate your knowledge of safety regulations and procedures.

- Tailor your resume to the specific job requirements.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Rigger Up Resume

- Plan, supervise, and execute rigging operations for heavy equipment, machinery, and structures.

- Inspect and certify rigging equipment, including cranes, hoists, slings, and other lifting devices.

- Develop and implement rigging plans to ensure the safe and efficient movement of loads.

- Operate and maintain cranes and other lifting equipment.

- Train and supervise rigging crew members.

- Troubleshoot and resolve rigging problems.

- Ensure compliance with all safety regulations and procedures.

Frequently Asked Questions (FAQ’s) For Rigger Up

What is a Rigger?

A Rigger is a skilled professional responsible for the safe and efficient movement of heavy equipment, machinery, and structures. They plan, supervise, and execute rigging operations, inspect and certify rigging equipment, develop and implement rigging plans, operate and maintain cranes and other lifting equipment, train and supervise rigging crew members, troubleshoot and resolve rigging problems, and ensure compliance with all safety regulations and procedures.

What skills are required to be a Rigger?

Riggers typically need a high school diploma or equivalent, as well as specialized training in rigging and heavy lifting. They must be physically fit and able to work in a variety of conditions, including heights and confined spaces. Riggers also need to have a good understanding of physics, mathematics, and engineering principles, as well as strong communication and teamwork skills.

What is the work environment of a Rigger like?

Riggers typically work in industrial settings, such as construction sites, factories, and warehouses. They may also work outdoors in all types of weather conditions. Riggers often work with heavy equipment and machinery, so they must be able to lift heavy objects and work in a physically demanding environment.

What are the career prospects for Riggers?

Riggers can advance their careers by gaining experience and developing their skills. They may also move into supervisory or management roles. With additional training and education, Riggers can also become certified as crane operators or other specialized rigging professionals.

What are the safety considerations for Riggers?

Riggers must always follow safety regulations and procedures to avoid accidents and injuries. They must be aware of the hazards associated with their work, such as working with heavy equipment, working in heights, and working in confined spaces. Riggers must also be able to identify and assess risks, and take steps to mitigate them.

What are the different types of rigging?

There are many different types of rigging, each with its own specific purpose. Some of the most common types of rigging include: crane rigging, which is used to lift and move heavy objects; marine rigging, which is used to secure ships and other vessels; and entertainment rigging, which is used to support and move equipment and scenery in the entertainment industry.