Are you a seasoned Kiln Transfer Operator seeking a new career path? Discover our professionally built Kiln Transfer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

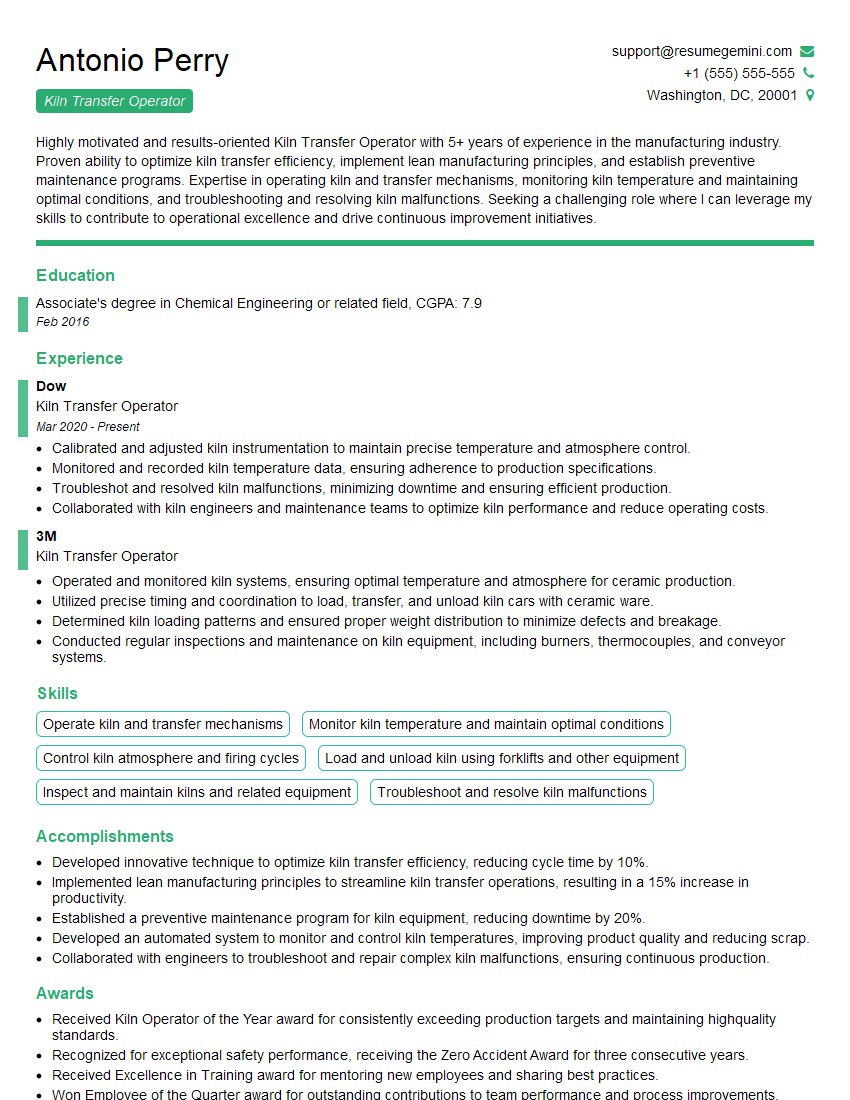

Antonio Perry

Kiln Transfer Operator

Summary

Highly motivated and results-oriented Kiln Transfer Operator with 5+ years of experience in the manufacturing industry. Proven ability to optimize kiln transfer efficiency, implement lean manufacturing principles, and establish preventive maintenance programs. Expertise in operating kiln and transfer mechanisms, monitoring kiln temperature and maintaining optimal conditions, and troubleshooting and resolving kiln malfunctions. Seeking a challenging role where I can leverage my skills to contribute to operational excellence and drive continuous improvement initiatives.

Education

Associate’s degree in Chemical Engineering or related field

February 2016

Skills

- Operate kiln and transfer mechanisms

- Monitor kiln temperature and maintain optimal conditions

- Control kiln atmosphere and firing cycles

- Load and unload kiln using forklifts and other equipment

- Inspect and maintain kilns and related equipment

- Troubleshoot and resolve kiln malfunctions

Work Experience

Kiln Transfer Operator

- Calibrated and adjusted kiln instrumentation to maintain precise temperature and atmosphere control.

- Monitored and recorded kiln temperature data, ensuring adherence to production specifications.

- Troubleshot and resolved kiln malfunctions, minimizing downtime and ensuring efficient production.

- Collaborated with kiln engineers and maintenance teams to optimize kiln performance and reduce operating costs.

Kiln Transfer Operator

- Operated and monitored kiln systems, ensuring optimal temperature and atmosphere for ceramic production.

- Utilized precise timing and coordination to load, transfer, and unload kiln cars with ceramic ware.

- Determined kiln loading patterns and ensured proper weight distribution to minimize defects and breakage.

- Conducted regular inspections and maintenance on kiln equipment, including burners, thermocouples, and conveyor systems.

Accomplishments

- Developed innovative technique to optimize kiln transfer efficiency, reducing cycle time by 10%.

- Implemented lean manufacturing principles to streamline kiln transfer operations, resulting in a 15% increase in productivity.

- Established a preventive maintenance program for kiln equipment, reducing downtime by 20%.

- Developed an automated system to monitor and control kiln temperatures, improving product quality and reducing scrap.

- Collaborated with engineers to troubleshoot and repair complex kiln malfunctions, ensuring continuous production.

Awards

- Received Kiln Operator of the Year award for consistently exceeding production targets and maintaining highquality standards.

- Recognized for exceptional safety performance, receiving the Zero Accident Award for three consecutive years.

- Received Excellence in Training award for mentoring new employees and sharing best practices.

- Won Employee of the Quarter award for outstanding contributions to team performance and process improvements.

Certificates

- Kiln Operator Certification

- OSHA Safety Certification

- EPA Clean Air Act Compliance Certification

- ASTM Standard Practice for Operating Kilns

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Kiln Transfer Operator

Highlight your technical skills and experience.

Employers will be looking for candidates with a strong understanding of kiln operation and maintenance. Be sure to list your experience in operating different types of kilns, as well as your knowledge of kiln temperature control, atmosphere control, and firing cycles.Quantify your accomplishments.

When describing your experience, be sure to quantify your accomplishments whenever possible. This will help employers to understand the impact of your work.Tailor your resume to the job description.

Take the time to read the job description carefully and tailor your resume to the specific requirements of the position. This will show employers that you are genuinely interested in the job and that you have the skills and experience they are looking for.Proofread your resume carefully.

Before you submit your resume, be sure to proofread it carefully for any errors. A well-written, error-free resume will make a good impression on potential employers.

Essential Experience Highlights for a Strong Kiln Transfer Operator Resume

- Operate kiln and transfer mechanisms to load and unload materials.

- Monitor kiln temperature and maintain optimal conditions for product quality.

- Control kiln atmosphere and firing cycles to ensure proper material processing.

- Inspect and maintain kilns and related equipment to prevent breakdowns and ensure efficient operation.

- Troubleshoot and resolve kiln malfunctions to minimize downtime and maintain production schedules.

- Implement lean manufacturing principles and best practices to improve kiln transfer efficiency and productivity.

- Collaborate with engineers and maintenance personnel to ensure optimal kiln performance and address complex technical issues.

Frequently Asked Questions (FAQ’s) For Kiln Transfer Operator

What is the role of a Kiln Transfer Operator?

A Kiln Transfer Operator is responsible for the operation and maintenance of kilns, which are used to heat and cool materials. Kiln Transfer Operators monitor kiln temperature and atmosphere, load and unload materials, and troubleshoot and resolve kiln malfunctions.

What are the qualifications for a Kiln Transfer Operator?

Most Kiln Transfer Operators have an associate’s degree in chemical engineering or a related field. They also have several years of experience operating and maintaining kilns.

What are the skills required for a Kiln Transfer Operator?

Kiln Transfer Operators need to have strong technical skills, including knowledge of kiln operation, maintenance, and troubleshooting. They also need to be able to work independently and as part of a team.

What is the work environment for a Kiln Transfer Operator like?

Kiln Transfer Operators typically work in a manufacturing environment. They may be exposed to heat, noise, and dust.

What is the salary range for a Kiln Transfer Operator?

The salary range for a Kiln Transfer Operator varies depending on experience and location. According to Salary.com, the median salary for a Kiln Transfer Operator in the United States is $64,000.

What is the job outlook for a Kiln Transfer Operator?

The job outlook for a Kiln Transfer Operator is expected to be good over the next few years. The demand for Kiln Transfer Operators is expected to increase as the manufacturing industry grows.

What are the benefits of working as a Kiln Transfer Operator?

There are many benefits to working as a Kiln Transfer Operator, including competitive pay, job security, and the opportunity to work with cutting-edge technology.