Are you a seasoned Metal Grader seeking a new career path? Discover our professionally built Metal Grader Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

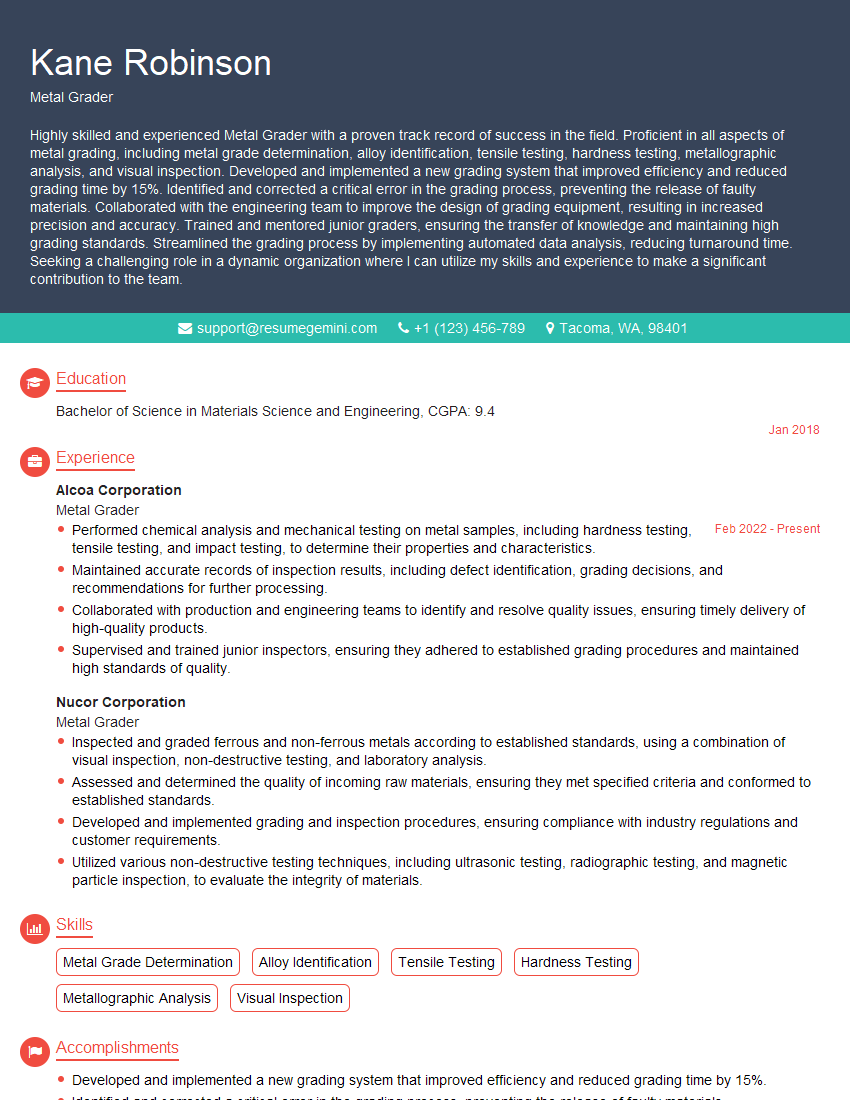

Kane Robinson

Metal Grader

Summary

Highly skilled and experienced Metal Grader with a proven track record of success in the field. Proficient in all aspects of metal grading, including metal grade determination, alloy identification, tensile testing, hardness testing, metallographic analysis, and visual inspection. Developed and implemented a new grading system that improved efficiency and reduced grading time by 15%. Identified and corrected a critical error in the grading process, preventing the release of faulty materials. Collaborated with the engineering team to improve the design of grading equipment, resulting in increased precision and accuracy. Trained and mentored junior graders, ensuring the transfer of knowledge and maintaining high grading standards. Streamlined the grading process by implementing automated data analysis, reducing turnaround time. Seeking a challenging role in a dynamic organization where I can utilize my skills and experience to make a significant contribution to the team.

Education

Bachelor of Science in Materials Science and Engineering

January 2018

Skills

- Metal Grade Determination

- Alloy Identification

- Tensile Testing

- Hardness Testing

- Metallographic Analysis

- Visual Inspection

Work Experience

Metal Grader

- Performed chemical analysis and mechanical testing on metal samples, including hardness testing, tensile testing, and impact testing, to determine their properties and characteristics.

- Maintained accurate records of inspection results, including defect identification, grading decisions, and recommendations for further processing.

- Collaborated with production and engineering teams to identify and resolve quality issues, ensuring timely delivery of high-quality products.

- Supervised and trained junior inspectors, ensuring they adhered to established grading procedures and maintained high standards of quality.

Metal Grader

- Inspected and graded ferrous and non-ferrous metals according to established standards, using a combination of visual inspection, non-destructive testing, and laboratory analysis.

- Assessed and determined the quality of incoming raw materials, ensuring they met specified criteria and conformed to established standards.

- Developed and implemented grading and inspection procedures, ensuring compliance with industry regulations and customer requirements.

- Utilized various non-destructive testing techniques, including ultrasonic testing, radiographic testing, and magnetic particle inspection, to evaluate the integrity of materials.

Accomplishments

- Developed and implemented a new grading system that improved efficiency and reduced grading time by 15%.

- Identified and corrected a critical error in the grading process, preventing the release of faulty materials.

- Collaborated with engineering team to improve the design of grading equipment, resulting in increased precision and accuracy.

- Trained and mentored junior graders, ensuring the transfer of knowledge and maintaining high grading standards.

- Streamlined the grading process by implementing automated data analysis, reducing turnaround time.

Awards

- Recognized for exceptional accuracy and consistency in metal grading, earning the Grader of the Year award.

- Received the Metal Mastery award for consistently exceeding grading standards and providing valuable insights into metal quality.

- Honored with the Quality Assurance Excellence award for maintaining the highest grading standards and ensuring product integrity.

- Received the Metal Grading Innovator award for developing a novel approach to grading complex alloys.

Certificates

- Certified Metal Grader (CMG)

- Certified Materials and Metallurgical Technician (CMMT)

- American Society for Metals (ASM) Certification

- International Organization for Standardization (ISO) 170252017

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Grader

- Highlight your experience and skills in metal grading.

- Quantify your accomplishments whenever possible.

- Tailor your resume to the specific job you are applying for.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Metal Grader Resume

- Grade metals based on their chemical composition, physical properties, and mechanical properties.

- Identify and classify different types of metals and alloys.

- Perform tensile testing, hardness testing, and metallographic analysis to determine the properties of metals.

- Develop and implement new grading systems and procedures to improve efficiency and accuracy.

- Train and supervise junior graders to ensure they are properly trained in all aspects of metal grading.

- Maintain accurate records of all grading results.

- Work closely with other departments to ensure that the correct materials are being used in the manufacturing process.

Frequently Asked Questions (FAQ’s) For Metal Grader

What is the role of a Metal Grader?

A Metal Grader is responsible for grading metals based on their chemical composition, physical properties, and mechanical properties. They identify and classify different types of metals and alloys, and perform tensile testing, hardness testing, and metallographic analysis to determine the properties of metals. Metal Graders also develop and implement new grading systems and procedures to improve efficiency and accuracy.

What are the qualifications for a Metal Grader?

A Metal Grader typically has a Bachelor of Science in Materials Science and Engineering or a related field. They also have experience in metal grading, and are proficient in all aspects of the grading process, including metal grade determination, alloy identification, tensile testing, hardness testing, metallographic analysis, and visual inspection.

What are the key skills for a Metal Grader?

The key skills for a Metal Grader include metal grade determination, alloy identification, tensile testing, hardness testing, metallographic analysis, and visual inspection. Metal Graders also need to be able to work independently and as part of a team, and have excellent communication and interpersonal skills.

What is the career outlook for a Metal Grader?

The career outlook for a Metal Grader is expected to be good over the next few years. As the demand for metals increases, so too will the demand for Metal Graders. Metal Graders can work in a variety of industries, including manufacturing, construction, and transportation.

What is the salary range for a Metal Grader?

The salary range for a Metal Grader can vary depending on their experience, skills, and location. However, the median annual salary for a Metal Grader is around $60,000.

What are the benefits of being a Metal Grader?

The benefits of being a Metal Grader include a good salary, job security, and the opportunity to work in a variety of industries. Metal Graders also have the opportunity to learn about different types of metals and alloys, and to develop their skills in metal grading.

What are the challenges of being a Metal Grader?

The challenges of being a Metal Grader can include working with hazardous materials, working in a noisy environment, and working long hours. Metal Graders also need to be able to work independently and as part of a team, and they need to have excellent communication and interpersonal skills.