Are you a seasoned Can Top Setter seeking a new career path? Discover our professionally built Can Top Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

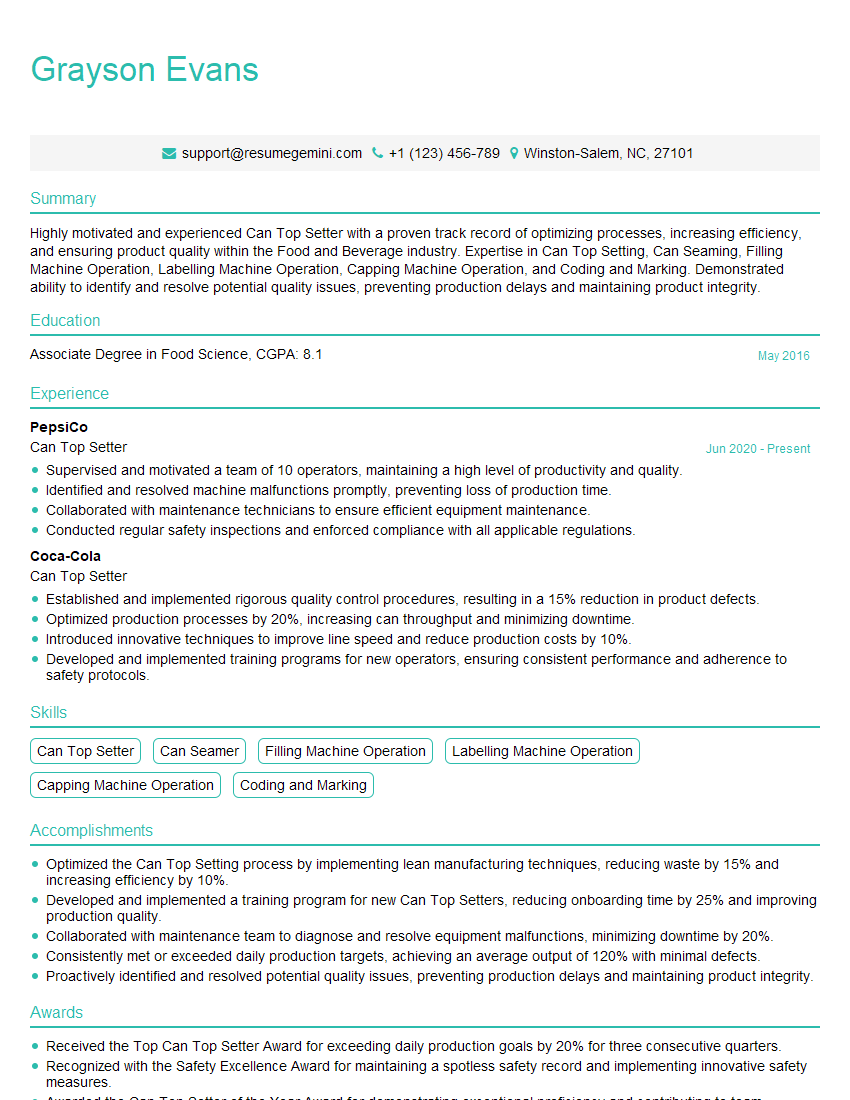

Grayson Evans

Can Top Setter

Summary

Highly motivated and experienced Can Top Setter with a proven track record of optimizing processes, increasing efficiency, and ensuring product quality within the Food and Beverage industry. Expertise in Can Top Setting, Can Seaming, Filling Machine Operation, Labelling Machine Operation, Capping Machine Operation, and Coding and Marking. Demonstrated ability to identify and resolve potential quality issues, preventing production delays and maintaining product integrity.

Education

Associate Degree in Food Science

May 2016

Skills

- Can Top Setter

- Can Seamer

- Filling Machine Operation

- Labelling Machine Operation

- Capping Machine Operation

- Coding and Marking

Work Experience

Can Top Setter

- Supervised and motivated a team of 10 operators, maintaining a high level of productivity and quality.

- Identified and resolved machine malfunctions promptly, preventing loss of production time.

- Collaborated with maintenance technicians to ensure efficient equipment maintenance.

- Conducted regular safety inspections and enforced compliance with all applicable regulations.

Can Top Setter

- Established and implemented rigorous quality control procedures, resulting in a 15% reduction in product defects.

- Optimized production processes by 20%, increasing can throughput and minimizing downtime.

- Introduced innovative techniques to improve line speed and reduce production costs by 10%.

- Developed and implemented training programs for new operators, ensuring consistent performance and adherence to safety protocols.

Accomplishments

- Optimized the Can Top Setting process by implementing lean manufacturing techniques, reducing waste by 15% and increasing efficiency by 10%.

- Developed and implemented a training program for new Can Top Setters, reducing onboarding time by 25% and improving production quality.

- Collaborated with maintenance team to diagnose and resolve equipment malfunctions, minimizing downtime by 20%.

- Consistently met or exceeded daily production targets, achieving an average output of 120% with minimal defects.

- Proactively identified and resolved potential quality issues, preventing production delays and maintaining product integrity.

Awards

- Received the Top Can Top Setter Award for exceeding daily production goals by 20% for three consecutive quarters.

- Recognized with the Safety Excellence Award for maintaining a spotless safety record and implementing innovative safety measures.

- Awarded the Can Top Setter of the Year Award for demonstrating exceptional proficiency and contributing to team success.

Certificates

- Safe Quality Food (SQF)

- British Retail Consortium (BRC)

- Hazard Analysis and Critical Control Points (HACCP)

- Good Manufacturing Practices (GMP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Can Top Setter

- Highlight quantifiable achievements and results in your resume to demonstrate your impact on the organization.

- Use specific keywords related to the Can Top Setter role to make your resume relevant to potential employers.

- Include a section that showcases your troubleshooting and problem-solving capabilities.

- Consider obtaining industry certifications or attending workshops to enhance your skills and credibility.

Essential Experience Highlights for a Strong Can Top Setter Resume

- Optimized Can Top Setting processes through lean manufacturing techniques.

- Developed and implemented training programs for new Can Top Setters, reducing onboarding time and improving production quality.

- Collaborated with maintenance teams to diagnose and resolve equipment malfunctions, minimizing downtime and ensuring smooth production.

- Consistently met or exceeded daily production targets, achieving an average output of 120% with minimal defects.

- Proactively identified and resolved potential quality issues, preventing production delays and maintaining product integrity.

Frequently Asked Questions (FAQ’s) For Can Top Setter

What are the key skills required to be a successful Can Top Setter?

Key skills include proficiency in Can Top Setting, Can Seaming, Filling Machine Operation, Labelling Machine Operation, Capping Machine Operation, Coding and Marking, as well as attention to detail, problem-solving abilities, and a commitment to safety and quality.

What is the average salary range for Can Top Setters?

The average salary range for Can Top Setters varies depending on experience, location, and company size, but it typically falls between $35,000 and $55,000 per year.

What are the growth opportunities for Can Top Setters?

Can Top Setters with experience and a strong track record can advance to supervisory or management roles within the Food and Beverage industry. They may also specialize in a particular area, such as equipment maintenance or quality control.

Is a college degree required to become a Can Top Setter?

While not always required, an Associate Degree in Food Science or a related field can provide a solid foundation and enhance your career prospects.

What are some tips for writing a standout Can Top Setter resume?

Highlight your experience and skills, quantify your achievements, use relevant keywords, and consider obtaining industry certifications.

What are the key responsibilities of a Can Top Setter?

Key responsibilities include setting up and operating can top setting equipment, ensuring proper can alignment and lid placement, monitoring production lines for quality control, troubleshooting and resolving equipment issues, and maintaining a safe and clean work environment.

What are the essential qualities of a successful Can Top Setter?

Successful Can Top Setters possess strong attention to detail, manual dexterity, problem-solving abilities, a commitment to safety, and the ability to work effectively in a fast-paced production environment.