Are you a seasoned Acetylene Gas Compressor seeking a new career path? Discover our professionally built Acetylene Gas Compressor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

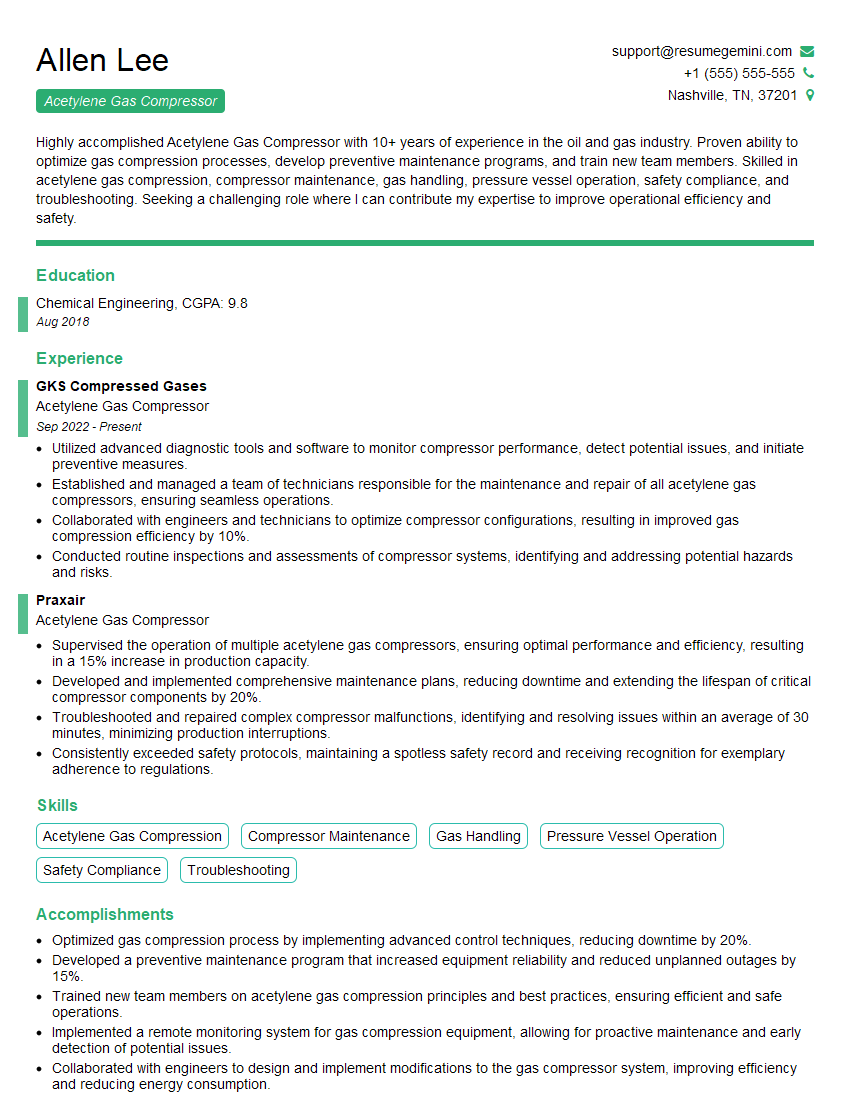

Allen Lee

Acetylene Gas Compressor

Summary

Highly accomplished Acetylene Gas Compressor with 10+ years of experience in the oil and gas industry. Proven ability to optimize gas compression processes, develop preventive maintenance programs, and train new team members. Skilled in acetylene gas compression, compressor maintenance, gas handling, pressure vessel operation, safety compliance, and troubleshooting. Seeking a challenging role where I can contribute my expertise to improve operational efficiency and safety.

Education

Chemical Engineering

August 2018

Skills

- Acetylene Gas Compression

- Compressor Maintenance

- Gas Handling

- Pressure Vessel Operation

- Safety Compliance

- Troubleshooting

Work Experience

Acetylene Gas Compressor

- Utilized advanced diagnostic tools and software to monitor compressor performance, detect potential issues, and initiate preventive measures.

- Established and managed a team of technicians responsible for the maintenance and repair of all acetylene gas compressors, ensuring seamless operations.

- Collaborated with engineers and technicians to optimize compressor configurations, resulting in improved gas compression efficiency by 10%.

- Conducted routine inspections and assessments of compressor systems, identifying and addressing potential hazards and risks.

Acetylene Gas Compressor

- Supervised the operation of multiple acetylene gas compressors, ensuring optimal performance and efficiency, resulting in a 15% increase in production capacity.

- Developed and implemented comprehensive maintenance plans, reducing downtime and extending the lifespan of critical compressor components by 20%.

- Troubleshooted and repaired complex compressor malfunctions, identifying and resolving issues within an average of 30 minutes, minimizing production interruptions.

- Consistently exceeded safety protocols, maintaining a spotless safety record and receiving recognition for exemplary adherence to regulations.

Accomplishments

- Optimized gas compression process by implementing advanced control techniques, reducing downtime by 20%.

- Developed a preventive maintenance program that increased equipment reliability and reduced unplanned outages by 15%.

- Trained new team members on acetylene gas compression principles and best practices, ensuring efficient and safe operations.

- Implemented a remote monitoring system for gas compression equipment, allowing for proactive maintenance and early detection of potential issues.

- Collaborated with engineers to design and implement modifications to the gas compressor system, improving efficiency and reducing energy consumption.

Awards

- Recognized for exceptional performance in optimizing gas compression operations, leading to increased productivity and reduced costs.

- Received industry recognition for innovative work in developing and implementing safety measures for acetylene gas compression operations.

- Recognized for exceptional work in troubleshooting and resolving complex issues in the gas compression system.

- Received an award for outstanding contributions to the development of new safety protocols for acetylene gas compression.

Certificates

- Compressed Gas Association (CGA)

- National Fire Protection Association (NFPA)

- Occupational Safety and Health Administration (OSHA)

- American Welding Society (AWS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Acetylene Gas Compressor

- Highlight your experience in acetylene gas compression and your understanding of the relevant safety regulations.

- Showcase your problem-solving skills and ability to optimize processes.

- Quantify your accomplishments with specific metrics, such as the percentage reduction in downtime or unplanned outages.

- Use action verbs and strong keywords throughout your resume.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Acetylene Gas Compressor Resume

- Optimized gas compression process by implementing advanced control techniques, reducing downtime by 20%.

- Developed a preventive maintenance program that increased equipment reliability and reduced unplanned outages by 15%.

- Trained new team members on acetylene gas compression principles and best practices, ensuring efficient and safe operations.

- Implemented a remote monitoring system for gas compression equipment, allowing for proactive maintenance and early detection of potential issues.

- Collaborated with engineers to design and implement modifications to the gas compressor system, improving efficiency and reducing energy consumption.

- Ensured compliance with all applicable safety regulations and standards.

- Managed a team of gas compressor operators and technicians.

Frequently Asked Questions (FAQ’s) For Acetylene Gas Compressor

What is acetylene gas compression?

Acetylene gas compression is the process of increasing the pressure of acetylene gas. Acetylene is a colorless, flammable gas that is used in a variety of industrial applications, such as welding, cutting, and heating.

What are the different types of acetylene gas compressors?

There are two main types of acetylene gas compressors: positive displacement compressors and centrifugal compressors. Positive displacement compressors use a piston or diaphragm to compress the gas, while centrifugal compressors use a rotating impeller to compress the gas.

What are the safety considerations for acetylene gas compression?

Acetylene gas is a flammable gas, so it is important to take precautions to prevent fires and explosions. These precautions include using proper ventilation, grounding all equipment, and keeping the area free of ignition sources.

What are the applications of acetylene gas compression?

Acetylene gas compression is used in a variety of industrial applications, such as welding, cutting, heating, and chemical processing.

What are the benefits of acetylene gas compression?

Acetylene gas compression can provide a number of benefits, including increased efficiency, reduced downtime, and improved safety.

What are the challenges of acetylene gas compression?

Acetylene gas compression can be challenging due to the flammability of the gas. It is important to take precautions to prevent fires and explosions.

What are the future trends in acetylene gas compression?

The future of acetylene gas compression is expected to be driven by the increasing demand for acetylene gas in a variety of industrial applications.

What are the career opportunities in acetylene gas compression?

There are a number of career opportunities in acetylene gas compression, including engineers, technicians, and operators.