Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tandem Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

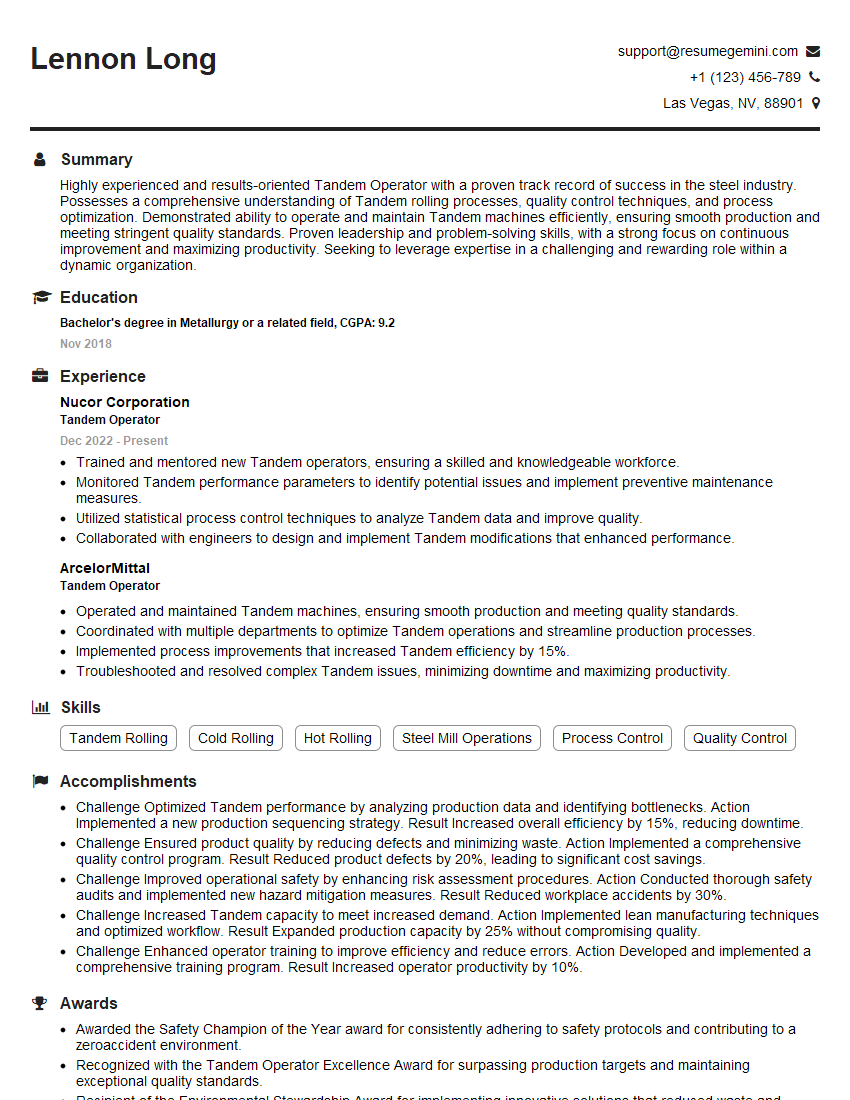

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tandem Operator

1. What are the key responsibilities of a Tandem Operator?

The key responsibilities of a Tandem Operator typically include:

- Operating and monitoring tandem rolling mill equipment to produce steel products.

- Adjusting mill settings and controls to ensure product quality and efficiency.

- Monitoring and maintaining equipment to prevent breakdowns and ensure safety.

- Troubleshooting and resolving production issues.

- Working with other operators and maintenance personnel to ensure smooth production flow.

2. Describe the different types of tandem rolling mills and their applications.

There are several types of tandem rolling mills, including:

Cold Rolling Mills:

- Used to reduce the thickness of steel strip at room temperature.

- Produces high-quality, precision-rolled products.

Hot Rolling Mills:

- Used to reduce the thickness of steel slabs or blooms at high temperatures.

- Produces semi-finished products for further processing.

Continuous Tandem Mills:

- Used for high-volume production of thin steel strip.

- Consists of multiple rolling stands arranged in series.

3. What are the safety precautions that must be followed when operating a tandem rolling mill?

Safety precautions for operating a tandem rolling mill include:

- Wearing appropriate personal protective equipment (PPE).

- Following lockout/tagout procedures before performing maintenance.

- Maintaining a clean and organized work area.

- Being aware of pinch points and other potential hazards.

- Receiving proper training and certification.

4. How do you calibrate and maintain the accuracy of tandem rolling mill equipment?

To calibrate and maintain the accuracy of tandem rolling mill equipment:

- Use precision measuring instruments, such as micrometers and thickness gauges.

- Follow manufacturer’s instructions for calibration procedures.

- Perform regular maintenance and inspections to identify and correct any deviations.

- Use statistical process control (SPC) techniques to monitor and improve accuracy.

5. What are the common quality defects that can occur during tandem rolling and how do you prevent them?

Common quality defects and prevention measures include:

- Edge cracking: Use proper lubrication and ensure uniform strip tension.

- Centerline cracking: Control rolling speed and temperature.

- Surface defects: Maintain clean rolling surfaces and optimize roll temperature.

- Dimensional variations: Calibrate equipment regularly and monitor process parameters.

6. How do you troubleshoot and resolve production issues on a tandem rolling mill?

To troubleshoot and resolve production issues:

- Identify the problem and its potential causes.

- Check equipment settings, sensors, and actuators.

- Inspect the material and process parameters.

- Consult with maintenance personnel or engineers if necessary.

- Implement corrective actions and monitor results.

7. How do you optimize the performance of a tandem rolling mill to improve productivity and efficiency?

To optimize performance:

- Maintain equipment in peak condition.

- Use advanced process control systems.

- Optimize rolling parameters, such as speed, tension, and temperature.

- Minimize downtime and improve setup times.

- Implement lean manufacturing principles.

8. Describe your experience with process control systems used in tandem rolling mills.

I have experience with various process control systems, including:

- Automated gauge control (AGC) systems.

- Tension control systems.

- Temperature control systems.

- Data acquisition and analysis systems.

9. How do you stay up-to-date on the latest technologies and best practices in tandem rolling?

To stay up-to-date:

- Attend industry conferences and workshops.

- Read technical publications and journals.

- Participate in online forums and discussions.

- Consult with equipment manufacturers and service providers.

10. What are your career goals and how does this position align with them?

My career goal is to become a highly skilled and experienced Tandem Operator. I am confident that this position will provide me with the opportunity to develop my skills, contribute to the company’s success, and advance my career in the steel industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tandem Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tandem Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tandem Operators are responsible for operating tandem bicycles, which are two bicycles connected together. They typically work in a team of two, with one operator in the front and the other in the back. Tandem Operators must be able to work well together and communicate effectively to ensure the safety of the passengers.

1. Pre-Ride Inspection

Before each ride, Tandem Operators are responsible for inspecting the tandem bicycle to ensure that it is safe to operate. This includes checking the tires, brakes, and gears. They must also make sure that the passengers are properly fitted to the bicycle and that they are wearing helmets.

2. Passenger Safety

Tandem Operators are responsible for the safety of the passengers. They must be aware of the surroundings and potential hazards, and they must take steps to avoid accidents. They must also be able to communicate clearly with the passengers to ensure that they understand the instructions.

3. Route Navigation

Tandem Operators are responsible for navigating the route. They must be familiar with the area and be able to make decisions about the best way to get to the destination. They must also be able to communicate with the passengers to let them know about upcoming turns or hazards.

4. Customer Service

Tandem Operators are responsible for providing excellent customer service. They must be friendly and helpful, and they must be able to answer any questions that the passengers may have. They must also be able to resolve any problems that may arise during the ride.

Interview Tips

Tandem Operators should prepare carefully for their interviews to increase their chances of making a positive impression and landing the job.

1. Research the Company and the Position

Before the interview, Tandem Operators should research the company and the position to learn about the company’s culture, values, and goals. They should also review the job description and make note of the required qualifications and skills.

2. Practice Your Answers to Common Interview Questions

Tandem Operators should practice answering common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. They should also be prepared to talk about their experience and skills, and how they can contribute to the company.

3. Dress Professionally

Tandem Operators should dress professionally for their interview. This means wearing a suit, dress, or other business attire. They should also make sure that their hair is neat and their nails are clean.

4. Be Enthusiastic and Positive

Tandem Operators should be enthusiastic and positive during their interview. They should show the interviewer that they are excited about the opportunity to work for the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tandem Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tandem Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.