Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Seed Cleaning Manager position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

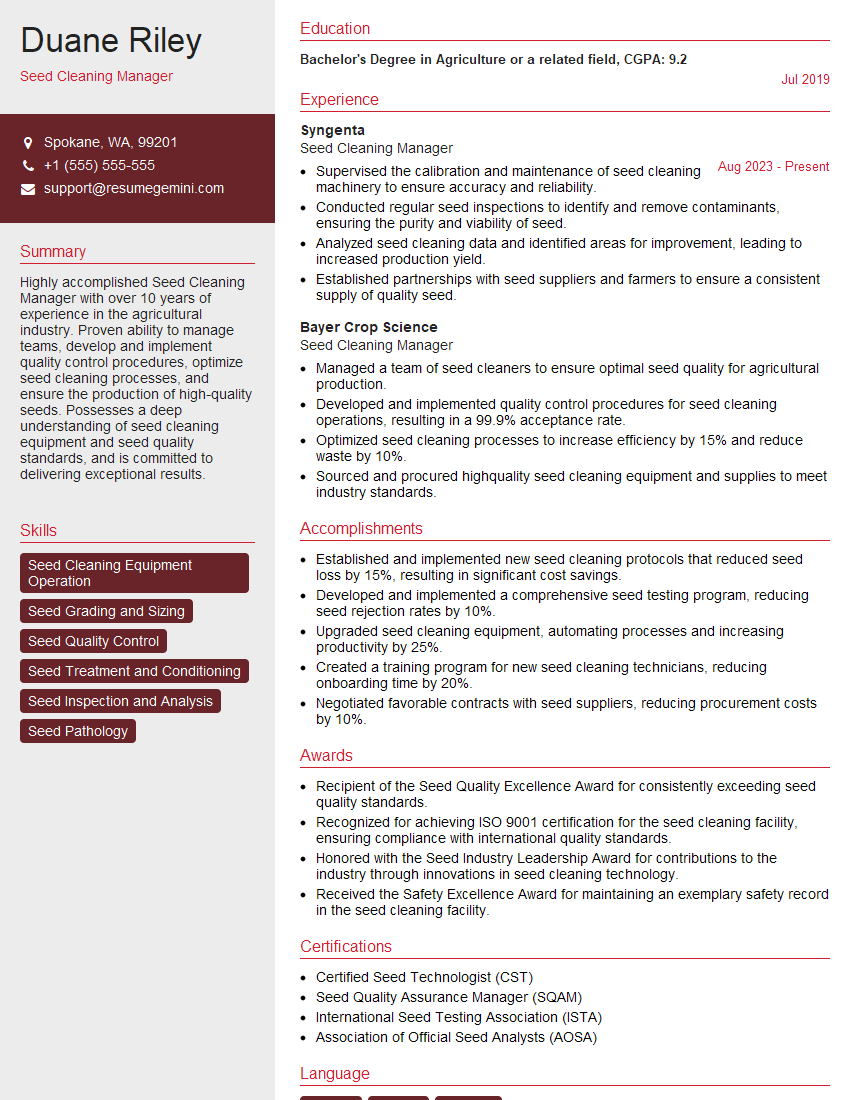

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Seed Cleaning Manager

1. Describe the different types of seed cleaning equipment you have experience using.

As a Seed Cleaning Manager, I have extensive experience utilizing a variety of seed cleaning equipment, including:

- Gravity separators: These machines separate seeds based on their weight and density, removing lighter impurities like chaff and dust.

- Air screen cleaners: These devices use an air current to remove lighter impurities and separate seeds by size.

- Magnetic separators: These machines remove ferrous metal impurities from seed lots, ensuring the safety and quality of the final product.

- Color sorters: These advanced machines utilize optical technology to detect and remove discolored or damaged seeds, improving seed quality and maximizing yield.

- Seed treaters: These devices apply protective coatings or treatments to seeds, enhancing their resistance to pests and diseases.

2. What are the key factors to consider when selecting seed cleaning equipment?

Factors to Consider:

- Type and quantity of seed being processed

- Desired level of purity and quality

- Budget and space constraints

- Required efficiency and throughput

- Maintenance and operating costs

Additional Considerations:

- Compatibility with existing equipment

- Availability of spare parts and technical support

- Environmental regulations and safety standards

3. How do you develop and implement seed cleaning protocols for different seed types?

To develop and implement effective seed cleaning protocols for different seed types, I follow a comprehensive process:

- Identify Seed Characteristics: Determine the specific characteristics of the seed type, including its size, shape, density, and impurities present.

- Equipment Selection: Select the appropriate seed cleaning equipment based on the identified seed characteristics and desired cleaning objectives.

- Protocol Development: Establish specific settings and operating parameters for each piece of equipment used in the cleaning process.

- Testing and Optimization: Conduct trial runs to fine-tune the protocol and optimize the efficiency and effectiveness of the cleaning process.

- Documentation and Monitoring: Document the developed protocols clearly and monitor the cleaning process regularly to ensure consistent results.

4. How do you ensure the quality of cleaned seeds and maintain compliance with industry standards?

To ensure the quality of cleaned seeds and maintain compliance with industry standards, I implement the following measures:

- Quality Control Measures: Establish rigorous quality control procedures throughout the cleaning process, including sampling and testing at various stages.

- Industry Standards Compliance: Adhere to established industry standards and regulations, such as those set by the International Seed Testing Association (ISTA).

- Traceability and Documentation: Maintain detailed records of all cleaning processes, including equipment used, settings, and results, ensuring traceability and accountability.

- Continuous Improvement: Regularly review and update quality control measures and protocols based on industry best practices and feedback from customers.

5. How do you handle and resolve unexpected issues or challenges during seed cleaning?

When faced with unexpected issues or challenges during seed cleaning, I adopt a systematic and proactive approach:

- Assessment and Diagnosis: Promptly identify and assess the issue, determining its root cause and potential impact on the cleaning process.

- Solution Development: Develop and implement appropriate solutions to address the issue, considering factors such as equipment settings, process optimization, or maintenance requirements.

- Communication and Coordination: Communicate the issue and the proposed solution to relevant stakeholders, including management, team members, and customers.

- Monitoring and Evaluation: Monitor the effectiveness of the implemented solution and make adjustments as needed to ensure optimal results.

6. Describe your experience in managing seed cleaning operations and optimizing productivity.

In managing seed cleaning operations, I focus on optimizing productivity and efficiency through:

- Process Optimization: Analyze and improve existing processes to identify and address bottlenecks, reducing downtime and maximizing throughput.

- Equipment Maintenance: Implement a comprehensive maintenance program to ensure equipment reliability and minimize disruptions.

- Team Management: Lead and motivate a team effectively, providing clear instructions, training, and support to maintain high productivity levels.

- Performance Monitoring: Establish key performance indicators (KPIs) to track productivity, identify areas for improvement, and make data-driven decisions.

7. How do you stay up-to-date on the latest seed cleaning technologies and best practices?

To stay current with the latest seed cleaning technologies and best practices, I actively engage in the following activities:

- Attending Conferences and Workshops: Regularly attend industry events to learn about new advancements and network with experts.

- Reading Technical Publications: Subscribe to industry journals and publications to stay informed about research and emerging technologies.

- Online Research and Networking: Utilize online resources, forums, and discussion groups to connect with peers and access the latest information.

- Collaboration with Suppliers and Partners: Collaborate with equipment suppliers and industry partners to gain insights into new technologies and best practices.

8. How do you ensure a safe and healthy work environment for your team and adhere to safety regulations?

To ensure a safe and healthy work environment for my team and adhere to safety regulations, I implement the following measures:

- Regular Safety Training: Conduct comprehensive safety training sessions for all team members, covering potential hazards and proper safety protocols.

- Equipment Inspections: Regularly inspect and maintain equipment to ensure it meets safety standards and operates properly.

- Personal Protective Equipment (PPE): Provide and enforce the use of appropriate PPE, such as respirators, gloves, and eye protection.

- Hazard Identification and Risk Assessment: Identify potential hazards and conduct risk assessments to develop and implement mitigation strategies.

9. How do you manage inventory to ensure the availability of seeds for cleaning and maintain optimal stock levels?

To manage inventory effectively and ensure the availability of seeds for cleaning while maintaining optimal stock levels, I implement the following strategies:

- Demand Forecasting: Utilize historical data and market trends to forecast demand and plan inventory levels accordingly.

- Supplier Relationships: Establish strong relationships with suppliers to secure reliable and timely deliveries.

- Inventory Tracking: Implement a robust inventory tracking system to monitor stock levels, identify potential shortages, and optimize ordering.

- Just-in-Time (JIT) Inventory Management: Adopt JIT principles to minimize inventory holding costs while ensuring the availability of seeds when needed.

10. How do you collaborate with other departments, such as sales and production, to ensure smooth operations?

To foster effective collaboration with other departments and ensure smooth operations, I adopt the following approaches:

- Regular Communication: Maintain open and frequent communication with sales and production teams to stay informed about market demands and production schedules.

- Shared Goals and Objectives: Align goals and objectives with other departments to ensure that everyone is working towards a common purpose.

- Cross-Functional Meetings: Participate in regular cross-functional meetings to facilitate information sharing, problem-solving, and decision-making.

- Process Integration: Work with other departments to integrate processes and streamline operations, eliminating potential bottlenecks and inefficiencies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Seed Cleaning Manager.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Seed Cleaning Manager‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Seed Cleaning Manager is a critical role within the seed industry, responsible for overseeing and managing the cleaning and processing of seed crops. They play a vital role in ensuring the quality, purity, and viability of seeds, which are essential for successful crop production.

1. Seed Cleaning Operations Management

Oversee and manage all aspects of seed cleaning operations, including planning, scheduling, and monitoring.

- Develop and implement quality control procedures to ensure the production of clean, high-quality seeds.

- Supervise and train seed cleaning staff on equipment operation and maintenance.

2. Seed Testing and Quality Control

Conduct or oversee seed testing to determine seed quality, viability, and purity according to established standards.

- Interpret test results and make recommendations for seed cleaning adjustments to improve quality.

- Establish and maintain records of seed quality and testing results.

3. Equipment Maintenance and Management

Manage and maintain seed cleaning equipment to ensure optimal performance and efficiency.

- Monitor equipment usage, identify maintenance needs, and schedule repairs.

- Supervise equipment upgrades and installations to improve cleaning efficiency.

4. Seed Storage and Inventory Control

Oversee the proper storage of cleaned seeds to maintain seed quality and viability.

- Manage seed inventory, including receiving, storing, and distributing seeds.

- Implement pest control measures to prevent seed contamination and damage.

Interview Tips

Preparing for an interview for the Seed Cleaning Manager position requires a combination of industry knowledge, technical expertise, and effective communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the seed industry, the company’s seed cleaning operations, and their mission and values.

- Visit the company website and industry news sources to gather information.

- Connect with industry professionals on LinkedIn to gain insights into the company.

2. Showcase Your Technical Skills

Demonstrate your expertise in seed cleaning techniques, seed testing methods, and equipment maintenance.

- Provide specific examples of successful seed cleaning projects you have managed.

- Discuss your understanding of quality control standards and seed testing methodologies.

3. Emphasize Communication and Leadership Abilities

Highlight your ability to lead a team, communicate effectively with stakeholders, and resolve issues efficiently.

- Describe your experience in managing teams and delegating responsibilities.

- Share examples of how you have successfully resolved challenges in seed cleaning operations.

4. Prepare Questions to Ask

Asking thoughtful questions demonstrates your interest in the position and the company.

- Inquire about the company’s future plans for seed cleaning operations.

- Ask about opportunities for professional development and growth within the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Seed Cleaning Manager, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Seed Cleaning Manager positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.