Are you gearing up for a career in Food Production Manager? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Food Production Manager and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

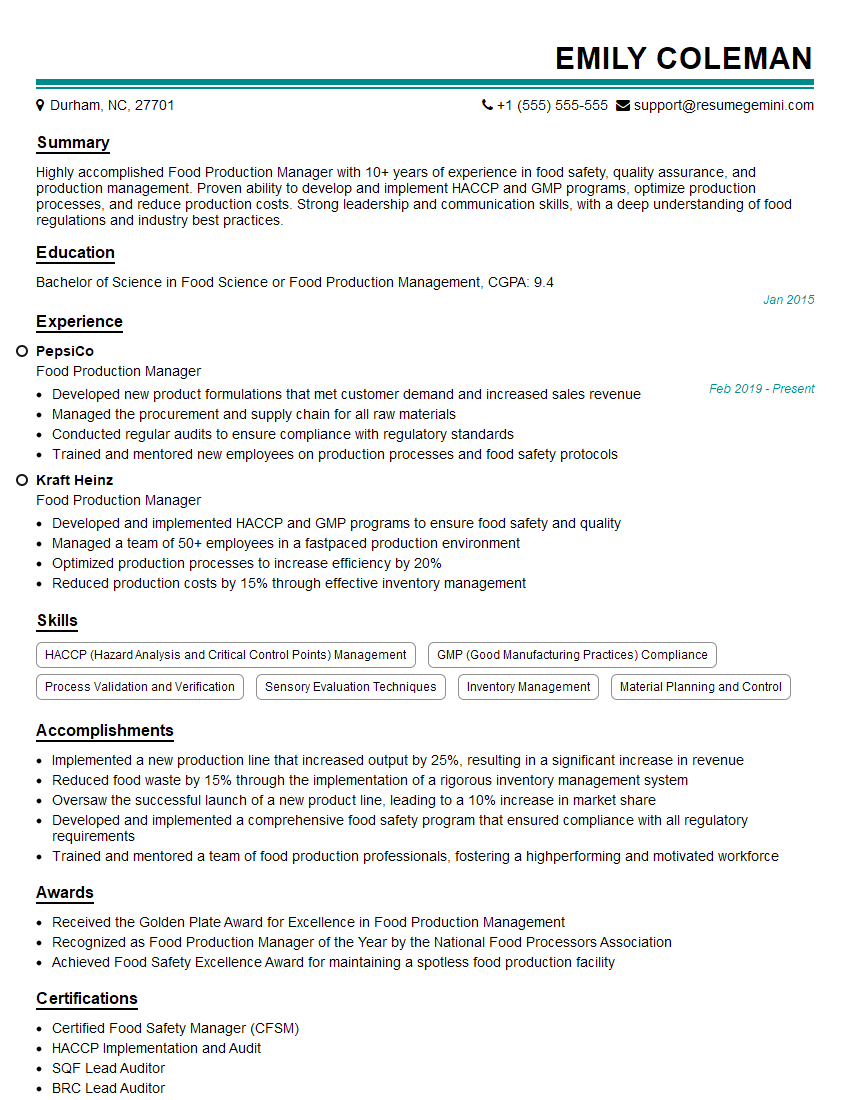

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Food Production Manager

1. How do you stay up-to-date on the latest food production trends and technologies?

I make it a priority to stay current on the latest food production trends and technologies. I regularly attend industry conferences, webinars, and trade shows to learn about new developments. I also subscribe to industry publications and online resources to stay informed about the latest news and research. In addition, I actively seek out opportunities to network with other food production professionals to exchange ideas and best practices.

2. What strategies have you successfully implemented to improve food safety and quality in previous roles?

HACCP and GMP Implementation

- Developed and implemented HACCP (Hazard Analysis and Critical Control Points) plans to identify and control food safety hazards throughout the production process.

- Established GMP (Good Manufacturing Practices) programs to ensure compliance with food safety regulations and industry standards.

Employee Training and Inspections

- Conducted regular food safety training for employees to enhance their knowledge and awareness of food safety principles.

- Implemented a comprehensive inspection program to monitor and verify adherence to food safety standards and procedures.

3. How do you manage production schedules and ensure efficient use of resources in a fast-paced food production environment?

- Utilize advanced planning techniques, such as production scheduling software, to optimize production schedules and resource allocation.

- Implement lean manufacturing principles to identify and eliminate waste and improve overall efficiency.

- Foster a collaborative work environment where employees are empowered to suggest and implement process improvements.

- Continuously monitor production data and identify areas for improvement to enhance efficiency and reduce costs.

4. How do you approach inventory management to minimize waste and maintain adequate stock levels?

- Implement an inventory management system to track inventory levels, manage stock replenishment, and optimize inventory turnover.

- Utilize just-in-time (JIT) principles to reduce inventory holding costs and improve supply chain efficiency.

- Conduct regular inventory audits to identify and address discrepancies, ensuring accuracy and preventing waste.

- Establish strong relationships with suppliers to ensure reliable deliveries and minimize the risk of stockouts.

5. What experience do you have in managing a team of food production employees and how do you motivate them?

- Successfully led and motivated teams of food production employees in previous roles, fostering a positive and productive work environment.

- Utilized various motivational techniques, such as recognition and rewards, to enhance employee engagement and productivity.

- Established clear goals and expectations, providing regular feedback and support to team members.

- Encouraged open communication and collaboration to promote teamwork and problem-solving.

6. How do you handle and resolve complaints or quality issues related to food products?

- Established a comprehensive complaint handling procedure to promptly and effectively address customer concerns.

- Thoroughly investigate complaints to identify root causes and develop corrective actions to prevent recurrence.

- Communicate openly and transparently with customers throughout the complaint resolution process.

- Implement quality control measures to ensure that products meet specifications and customer expectations.

7. What steps do you take to ensure compliance with regulatory requirements and industry standards in food production?

- Stay updated on regulatory changes and industry best practices through ongoing education and training.

- Develop and implement policies and procedures to ensure compliance with all applicable regulations.

- Conduct regular internal audits to identify and address any areas of non-compliance.

- Work closely with regulatory agencies to ensure that the production facility meets all requirements.

8. How do you manage and allocate resources efficiently in a food production environment, especially during periods of high demand or unexpected events?

- Utilize resource management software and techniques to optimize resource allocation and minimize waste.

- Implement flexible production schedules and cross-training programs to ensure that resources are available where and when needed.

- Collaborate with other departments, such as procurement and logistics, to ensure timely and cost-effective resource acquisition.

- Identify and address bottlenecks and inefficiencies to improve resource utilization and productivity.

9. How do you stay informed about emerging food technologies and their potential impact on the food production industry?

- Actively participate in industry organizations and attend conferences to learn about new technologies and trends.

- Subscribe to industry publications and online resources to stay up-to-date on the latest advancements.

- Collaborate with research institutions and technology providers to explore and evaluate emerging technologies.

- Assess the potential impact of new technologies on food production processes, product development, and consumer preferences.

10. What are your strategies for improving food production efficiency and reducing operational costs?

- Implement lean manufacturing principles to eliminate waste and streamline production processes.

- Utilize data analytics to identify areas for improvement and optimize production schedules.

- Invest in automation and robotics to increase efficiency and reduce labor costs.

- Negotiate favorable contracts with suppliers and vendors to minimize purchasing expenses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Food Production Manager.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Food Production Manager‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Food Production Manager is responsible for the overall operation of the production area, including planning, scheduling, and directing production activities. They ensure that all food is produced in a safe and efficient manner, and that it meets all quality standards.

1. Plan and schedule production activities

The Food Production Manager works with other departments to develop production plans and schedules. They must consider factors such as demand, availability of ingredients, and production capacity. They must also ensure that production is efficient and that all products are produced on time.

- Develop and implement production plans and schedules.

- Coordinate with other departments to ensure that all production needs are met.

2. Supervise production staff

The Food Production Manager supervises a team of production staff. They must provide training and guidance, and ensure that all staff members are following production procedures. They must also address any problems that arise and ensure that production is running smoothly.

- Supervise and train production staff.

- Ensure that all production procedures are followed.

3. Monitor food safety and quality

The Food Production Manager is responsible for food safety and quality. They must ensure that all food is produced in a safe and sanitary manner, and that it meets all quality standards. They must also conduct regular inspections and audits to ensure that all food production procedures are being followed.

- Monitor food safety and quality.

- Conduct regular inspections and audits.

4. Control costs

The Food Production Manager is responsible for controlling costs. They must ensure that production is efficient and that all costs are minimized. They must also work with other departments to identify and implement cost-saving measures.

- Control costs and identify cost-saving measures.

- Work with other departments to improve efficiency.

Interview Tips

Before the interview, it is important to research the company and the position. You should also practice answering common interview questions. Here are some additional tips for a successful interview:

1. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed.

2. Be on time

Punctuality shows that you are respectful of the interviewer’s time. Make sure to arrive at the interview location on time, or even a few minutes early.

3. Be prepared to answer common interview questions

Some of the most common interview questions include: “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” It is important to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

4. Ask questions

Asking questions shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role. Some good questions to ask include: “What are the biggest challenges facing the company right now?” and “What are the company’s goals for the next year?”

5. Follow up

After the interview, it is important to follow up with the interviewer. This shows that you are still interested in the position and that you appreciate their time. You can send a thank-you note or email, or you can call the interviewer to check on the status of your application.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Food Production Manager, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Food Production Manager positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.