Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Machine Stoppage Frequency Checker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Machine Stoppage Frequency Checker so you can tailor your answers to impress potential employers.

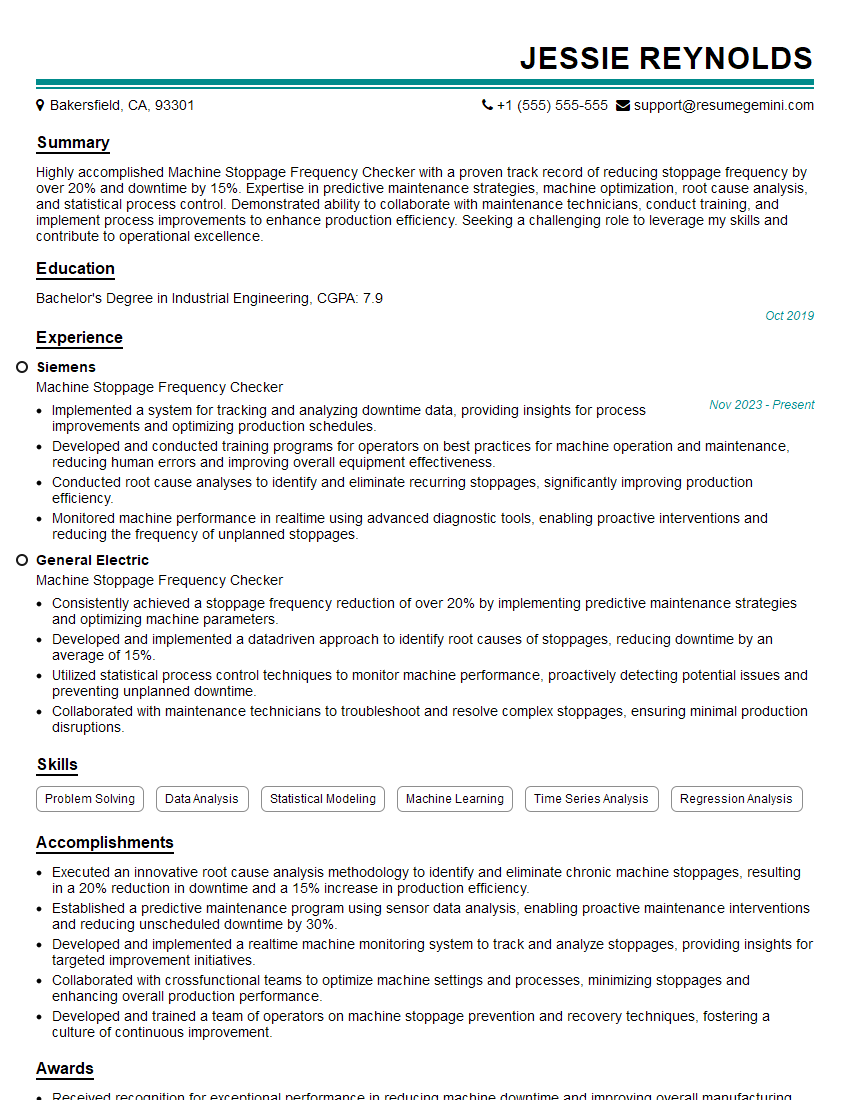

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Stoppage Frequency Checker

1. How do you perform a visual inspection of machines to identify potential issues that may lead to stoppages?

- Inspect all critical components for signs of wear, damage, or misalignment.

- Check for any loose connections, broken wires, or leaking fluids.

- Listen for unusual noises or vibrations that may indicate a problem.

- Use a checklist or inspection form to ensure thorough and consistent inspections.

2. Describe the different types of data you collect during machine stoppage frequency analysis.

Types of Data Collected

- Machine downtime duration and frequency

- Reason for stoppage (e.g., mechanical failure, setup, operator error)

- Failure mode and severity (e.g., catastrophic, major, minor)

- Operator notes or observations

- Environmental factors (e.g., temperature, humidity)

Methods of Data Collection

- Machine logs and sensors

- Manual observations and checklists

- Interviews with operators and maintenance personnel

- Statistical analysis software

3. How do you analyze data to identify patterns and trends in machine stoppages?

- Use statistical methods to calculate downtime metrics, such as mean time between failures (MTBF) and mean time to repair (MTTR).

- Create Pareto charts and other visual aids to identify the most common reasons for stoppages.

- Perform root cause analysis to determine the underlying causes of stoppages.

- Use regression analysis to identify relationships between stoppages and potential influencing factors (e.g., operator skill, maintenance schedules).

4. What are some common causes of machine stoppages and how can they be prevented?

- Mechanical failures: Regular maintenance, predictive maintenance, and proper lubrication can help prevent mechanical breakdowns.

- Operator errors: Training, clear operating procedures, and ergonomic improvements can reduce human-related stoppages.

- Material issues: Ensuring the quality of raw materials, proper storage, and handling can prevent stoppages caused by defective materials.

- Process variability: Standardization of processes, optimization of process parameters, and control of environmental factors can minimize process-related stoppages.

- Electrical issues: Regular inspections, proper grounding, and surge protection can prevent electrical failures.

5. Describe the role of predictive maintenance in reducing machine stoppages.

- Predictive maintenance involves monitoring machine parameters (e.g., vibration, temperature) to detect early signs of potential problems.

- By identifying and addressing these issues before they cause failures, predictive maintenance can significantly reduce downtime and improve machine reliability.

- Common predictive maintenance techniques include vibration analysis, thermography, oil analysis, and ultrasonic testing.

6. How do you communicate your findings and recommendations to management and other stakeholders?

- Prepare clear and concise reports that summarize the data analysis, identify root causes, and provide recommendations.

- Use visual aids, such as charts and graphs, to present findings in a visually appealing and impactful way.

- Present findings and recommendations to management and other stakeholders in person or through meetings.

- Be prepared to answer questions and discuss the implications of your findings.

7. What are some best practices for continuous improvement in machine stoppage reduction?

- Establish a culture of continuous improvement where employees are encouraged to identify and report machine issues.

- Regularly review and update machine maintenance schedules and procedures.

- Implement a system for tracking and analyzing machine stoppage data.

- Use statistical process control techniques to monitor machine performance and identify areas for improvement.

- Provide ongoing training to operators and maintenance personnel.

8. What are the key performance indicators (KPIs) that you track to measure the effectiveness of your machine stoppage reduction efforts?

- Mean time between failures (MTBF)

- Mean time to repair (MTTR)

- Overall equipment effectiveness (OEE)

- Percentage of downtime due to different reasons

- Number of stoppages per shift or per hour

9. Describe a situation where you successfully implemented a strategy to reduce machine stoppages in a manufacturing environment.

- Problem: Frequent machine stoppages due to bearing failures.

- Analysis: Vibration analysis identified excessive vibration in the bearings.

- Solution: Implemented a predictive maintenance program to monitor bearing vibration and replace bearings before failure.

- Result: Machine stoppages due to bearing failures reduced by 70%.

10. How do you stay up-to-date on the latest industry trends and best practices in machine stoppage reduction?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Participate in online forums and discussion groups.

- Network with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Stoppage Frequency Checker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Stoppage Frequency Checker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Stoppage Frequency Checkers are responsible for monitoring and recording the frequency of machine stoppages in a production environment. Their key responsibilities include:

1. Data Collection and Analysis

They collect data on machine stoppages, including the time, duration, and reason for each stoppage.

- Observing and recording machine stoppages

- Identifying and classifying the causes of stoppages

2. Reporting and Analysis

They prepare and present reports on machine stoppage frequency, identifying trends and patterns.

- Compiling and analyzing data on machine stoppages

- Identifying areas for improvement in machine performance

3. Troubleshooting and Problem Solving

They assist in troubleshooting and resolving machine stoppage issues, working with maintenance teams to identify and address root causes.

- Identifying and resolving machine stoppage issues

- Collaborating with maintenance teams to improve machine efficiency

4. Process Improvement

They participate in process improvement initiatives aimed at reducing machine stoppages and enhancing production efficiency.

- Developing and implementing strategies to reduce machine stoppages

- Optimizing machine performance through data analysis and process improvements

Interview Tips

Preparing for an interview for the role of Machine Stoppage Frequency Checker requires a comprehensive approach that includes researching the position, practicing common interview questions, and showcasing relevant skills and experience.

1. Research the Role and Company

Familiarize yourself with the job description, the company’s website, and industry-specific publications to gain a thorough understanding of the role and the company’s culture and values.

- Review the job description thoroughly, paying attention to the key responsibilities and qualifications

- Visit the company’s website to learn about their products, services, and company culture

2. Practice Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and motivation for the role. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Tell me about your experience in collecting and analyzing data on machine stoppages.

- Describe a time when you successfully identified and resolved a machine stoppage issue.

3. Showcase Relevant Skills and Experience

Highlight your skills and experience that are directly relevant to the role. Quantify your accomplishments whenever possible to demonstrate your impact.

- Emphasize your proficiency in data collection and analysis techniques

- Provide examples of your problem-solving abilities and experience in troubleshooting machine issues

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest in the role and the company. Prepare questions that seek to clarify the company’s goals, challenges, and opportunities.

- What are the company’s current goals and priorities for reducing machine stoppages?

- Can you provide more details about the team I would be working with?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Stoppage Frequency Checker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!