Are you gearing up for an interview for a Metal Flow Coordinator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Metal Flow Coordinator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

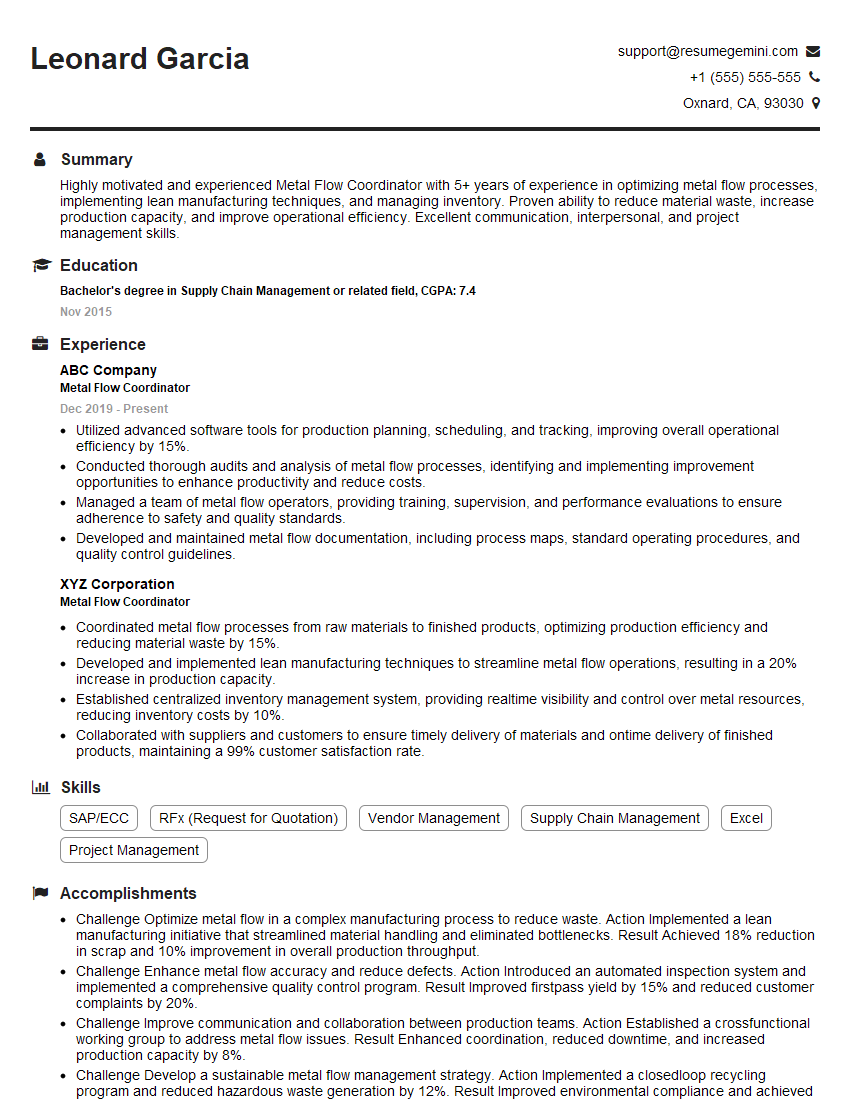

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Flow Coordinator

1. Describe your understanding of the primary responsibilities of a Metal Flow Coordinator?

As a Metal Flow Coordinator, my key responsibilities encompass:

- Managing the flow of metal materials throughout the production process

- Coordinating with suppliers, production teams, and quality control to ensure timely delivery and quality of materials

- Monitoring inventory levels and forecasting future requirements

- Optimizing production schedules to minimize waste and maximize efficiency

- Developing and implementing continuous improvement initiatives to enhance metal flow processes

2. How do you ensure the efficient flow of metal materials within a complex production environment?

Coordinating with stakeholders

- Maintain regular communication with suppliers, production managers, and quality control personnel

- Coordinate delivery schedules and resolve any issues promptly

- Provide timely updates on material availability and production progress

Tracking and monitoring

- Utilize inventory management systems to track metal flow in real-time

- Conduct regular audits to identify bottlenecks and inefficiencies

- Monitor production schedules and adjust material flow accordingly

Continuous improvement

- Analyze data to identify areas for improvement

- Implement corrective actions and track their effectiveness

- Collaborate with cross-functional teams to optimize metal flow processes

3. How do you manage the inventory of metal materials to prevent shortages or surpluses?

Effective inventory management is crucial to ensure uninterrupted production. My approach includes:

- Establishing minimum and maximum inventory levels for each type of metal material

- Using forecasting techniques to predict future demand

- Collaborating with suppliers to optimize delivery schedules

- Implementing inventory control systems to track material usage and identify trends

- Conducting regular inventory audits to verify accuracy and prevent discrepancies

4. What optimization techniques do you employ to minimize waste and maximize efficiency in metal flow processes?

I utilize various optimization techniques to enhance efficiency and reduce waste. These include:

- Layout optimization: Designing production lines and storage areas for optimal material flow

- Scheduling optimization: Using algorithms to sequence production orders efficiently

- Lean manufacturing principles: Eliminating waste and improving productivity

- Six Sigma: Identifying and eliminating defects in metal flow processes

- Collaboration with production and engineering teams: Sharing insights and identifying opportunities for process improvements

5. Describe your experience in implementing continuous improvement initiatives to enhance metal flow processes.

Process analysis

- Conducting value stream mapping to identify areas for improvement

- Analyzing data to identify bottlenecks and inefficiencies

- Gathering feedback from stakeholders to understand process challenges

Improvement implementation

- Developing and implementing corrective actions to address identified issues

- Collaborating with cross-functional teams to implement process improvements

- Monitoring the effectiveness of implemented changes

Continuous monitoring

- Tracking key performance indicators to measure the impact of improvements

- Conducting regular audits to identify any deviations from established standards

- Seeking feedback from stakeholders to evaluate the effectiveness of implemented changes

6. How do you prioritize and manage multiple projects and tasks in a fast-paced production environment?

Prioritization and task management are critical in a demanding production environment. My approach involves:

- Utilizing project management tools to organize and track tasks

- Establishing clear deadlines and assigning responsibilities

- Prioritizing tasks based on urgency and impact

- Delegating tasks to team members when appropriate

- Communicating regularly with stakeholders to provide updates and resolve issues

7. Describe how you ensure the quality of metal materials used in production.

Supplier qualification

- Conducting thorough supplier assessments to evaluate their quality systems and capabilities

- Establishing clear quality standards and specifications for metal materials

- Collaborating with quality control to develop inspection and testing procedures

Material inspection

- Inspecting incoming materials against established standards

- Utilizing non-destructive testing techniques to ensure material integrity

- Identifying and segregating any non-conforming materials

Continuous monitoring

- Monitoring production processes to ensure adherence to quality standards

- Conducting regular audits to identify any quality issues

- Collaborating with production and quality control teams to resolve any quality deviations

8. How do you handle unexpected disruptions or challenges in the metal flow process?

In the event of disruptions or challenges, I take the following steps:

- Assessing the situation and identifying the root cause

- Communicating the issue to stakeholders and providing updates

- Developing and implementing contingency plans to minimize impact

- Collaborating with cross-functional teams to find solutions

- Implementing corrective actions to prevent similar disruptions in the future

9. What software tools and technologies are you proficient in using for metal flow management?

I am well-versed in the following software tools and technologies:

- Enterprise Resource Planning (ERP) systems for inventory management and production scheduling

- Material requirements planning (MRP) software for forecasting and planning

- Computer-aided manufacturing (CAM) software for optimizing production processes

- Data analytics tools for analyzing metal flow data and identifying improvement opportunities

- Quality control software for managing inspections and testing

10. Describe your understanding of the safety regulations and best practices related to metal flow management.

I am fully aware of the safety regulations and best practices associated with metal flow management. These include:

- Proper handling and storage of metal materials

- Compliance with OSHA and other regulatory standards

- Use of personal protective equipment (PPE)

- Emergency response procedures

- Continuous training and education on safety protocols

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Flow Coordinator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Flow Coordinator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Flow Coordinators play a crucial role in optimizing metal flow within a manufacturing facility. They serve as the central point of coordination for all metal-related activities, ensuring that materials are efficiently received, processed, and delivered throughout the production process.

1. Metal Procurement and Vendor Management

Manage relationships with metal suppliers and negotiate favorable contracts.

- Forecast material requirements and place timely orders.

- Monitor vendor performance and resolve any issues.

2. Inventory Control and Management

Track and manage metal inventory levels.

- Receive and process incoming metal shipments.

- Maintain accurate inventory records.

3. Production Scheduling and Coordination

Coordinate with production planners to ensure timely delivery of metal to production lines.

- Allocate metal to specific production orders.

- Monitor production progress and make adjustments as needed.

4. Quality Control and Inspection

Inspect incoming and outgoing metal to ensure quality standards are met.

- Perform visual inspections and verify metal specifications.

- Coordinate with quality assurance department to investigate any issues.

Interview Tips

Preparing thoroughly for an interview is essential to impress the hiring manager and increase your chances of success. Here are some tips to help you ace the interview for a Metal Flow Coordinator position:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends.

- Visit the company website and social media pages.

- Read industry news and reports.

2. Practice Answering Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and the job responsibilities.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Quantify your accomplishments to demonstrate your impact.

3. Highlight Your Relevant Experience

Emphasize your experience in metal procurement, inventory management, production planning, or quality control.

- Provide specific examples of your accomplishments.

- Explain how your skills align with the job requirements.

4. Ask Thoughtful Questions

Asking well-informed questions during the interview shows that you are engaged and interested in the position.

- Prepare questions about the company’s metal flow process.

- Inquire about opportunities for professional development.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Metal Flow Coordinator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.