Are you gearing up for an interview for a Melter Clerk position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Melter Clerk and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

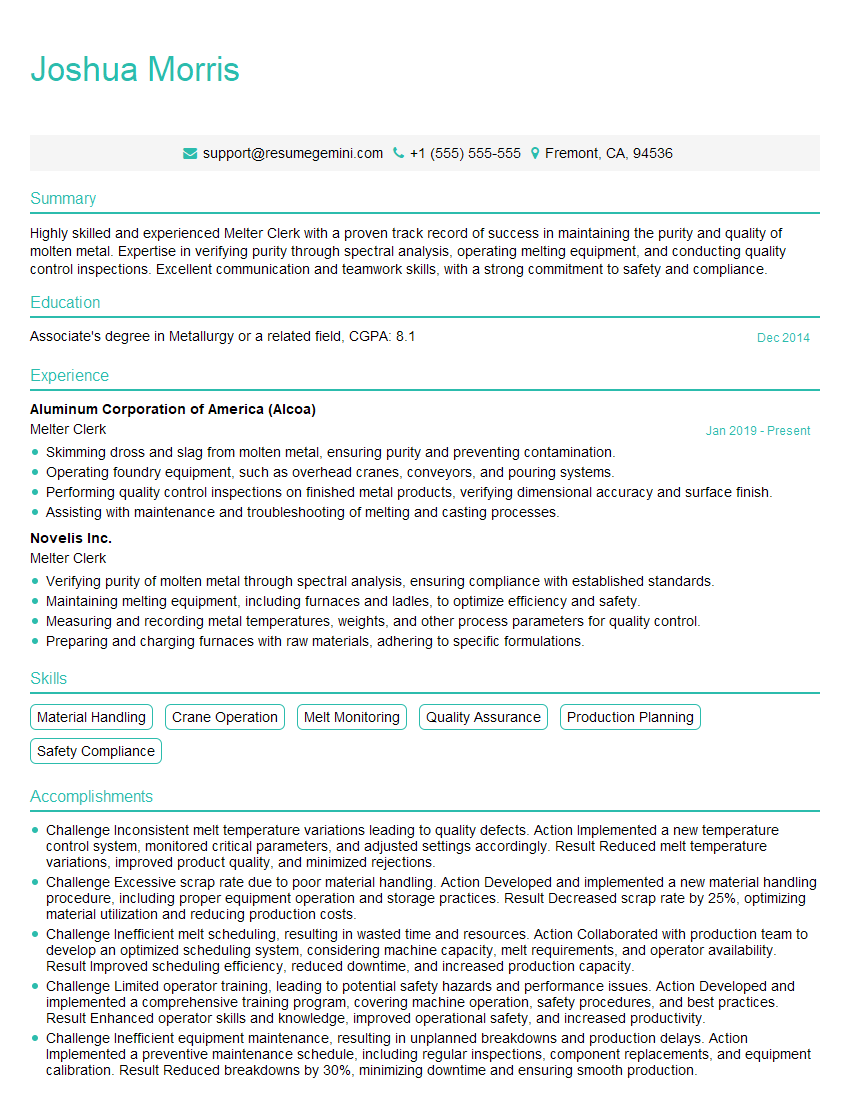

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Melter Clerk

1. Describe the process of melting metal in a furnace.

The process of melting metal in a furnace involves several steps:

- Charging the Furnace: The furnace is loaded with the metal scraps or raw materials to be melted.

- Heating: The furnace is heated using fuel sources such as natural gas, electricity, or oil. The temperature is gradually raised to reach the melting point of the metal.

- Melting: As the temperature rises, the metal begins to melt and form a molten pool at the bottom of the furnace.

- Superheating: The molten metal is further heated beyond its melting point to achieve the desired temperature and fluidity.

- Holding: The molten metal is held at the desired temperature for a specific period to ensure uniformity and remove any impurities or gases.

- Tapping: Once the metal is ready, it is tapped or drained out of the furnace into molds or containers for further processing.

2. What are the different types of furnaces used for metal melting?

Electric Arc Furnace (EAF):

- Uses electric arcs to generate heat.

- Melts scrap metal using high-power electrodes.

Induction Furnace:

- Uses electromagnetic induction to generate eddy currents in the metal.

- Melts metal without direct contact with heating elements.

Cupola Furnace:

- Uses coke to generate heat and melt iron.

- Suitable for large-scale iron production.

Open-Hearth Furnace:

- Uses a shallow hearth and regenerative burners to heat metal.

- Produces high-quality steel.

3. What are the key parameters to control during metal melting?

- Temperature: Maintaining the correct temperature is crucial to ensure proper melting and prevent overheating or freezing.

- Atmosphere: Controlling the atmosphere inside the furnace is essential to prevent oxidation and impurities in the molten metal.

- Chemical Composition: Monitoring and adjusting the chemical composition of the molten metal is necessary to meet the desired specifications.

- Holding Time: Ensuring sufficient holding time allows for homogenization and removal of impurities.

- Melt Rate: Controlling the rate of melting optimizes furnace efficiency and prevents overheating or incomplete melting.

4. What safety precautions should be taken during metal melting operations?

- Wear appropriate personal protective equipment (PPE) such as heat-resistant clothing, gloves, and masks.

- Follow established operating procedures and safety guidelines.

- Maintain a clean and organized work area.

- Use proper ventilation and extraction systems to remove fumes and gases.

- Have an emergency plan in place for potential accidents or incidents.

- Be aware of the hazards associated with handling molten metal and high temperatures.

5. What are the common defects that can occur during metal melting and how can they be prevented?

Porosity:

Shrinkage Cavities:

Cold Shut:

Hot Tears:

6. How do you measure and control the temperature of molten metal?

- Thermocouples: Inserted into the molten metal to measure temperature directly.

- Pyrometers: Measure temperature by detecting infrared radiation emitted from the molten metal.

- Optical Temperature Sensors: Use cameras to capture images of the molten metal and determine temperature based on the emitted light.

- Control Systems: Automated systems that regulate the furnace temperature based on sensor inputs.

7. What is the role of fluxes in metal melting?

- Remove Impurities: Fluxes react with impurities in the molten metal, forming slag that floats to the surface and can be removed.

- Protect the Molten Metal: Fluxes create a protective layer that prevents oxidation and contamination.

- Control Surface Tension: Fluxes can alter the surface tension of the molten metal, making it more fluid and easier to pour.

8. How do you maintain the quality of molten metal?

- Chemical Analysis: Regular sampling and analysis to ensure the metal meets the desired composition.

- Temperature Control: Maintaining the correct temperature range to prevent defects and ensure proper solidification.

- Flux Usage: Using appropriate fluxes to remove impurities and protect the molten metal.

- Degassing: Removing dissolved gases from the molten metal to prevent porosity.

- Proper Pouring Techniques: Correct pouring practices minimize defects and ensure the desired metal properties.

9. What are the environmental considerations in metal melting operations?

- Air Pollution: Emissions of fumes, gases, and particulates can be controlled using filters and scrubbers.

- Water Pollution: Wastewater containing heavy metals or chemicals must be treated before discharge.

- Solid Waste: Slag, dross, and other byproducts need to be properly disposed of or recycled.

- Energy Efficiency: Optimizing furnace operations and using energy-efficient technologies can reduce environmental impact.

10. Describe your experience in troubleshooting common problems encountered during metal melting.

I have encountered various problems during metal melting and have developed a systematic approach to troubleshooting:

- Identify Symptoms: Observe the process and molten metal for any unusual behavior or defects.

- Check Parameters: Verify temperature, atmosphere, chemical composition, and other critical parameters.

- Review Process: Examine the melting procedure, equipment operation, and raw materials used.

- Identify Root Cause: Analyze the data to determine the most likely cause of the problem.

- Implement Solutions: Develop and implement appropriate solutions to address the root cause.

- Monitor and Evaluate: Track the effectiveness of the solutions and make adjustments as necessary.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Melter Clerk.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Melter Clerk‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Melter Clerk’s responsibilities typically include:

1. Melt planning and scheduling

Planning and scheduling the melting process to meet customer orders and production requirements.

- Determining the required metal alloys, quantities, and melting parameters.

- Coordinating with the production team to ensure the availability of raw materials and equipment.

2. Furnace operation

Operating and monitoring melting furnaces to produce molten metal according to specifications.

- Setting up and calibrating furnaces.

- Controlling temperature, pressure, and other process parameters.

3. Quality control

Conducting quality checks on raw materials, molten metal, and finished products to ensure adherence to standards.

- Performing chemical analysis and physical testing.

- Maintaining records of quality control results.

4. Equipment maintenance

Performing routine maintenance and repairs on melting equipment to ensure optimal performance.

- Inspecting and cleaning furnaces.

- Replacing worn parts and making adjustments.

Interview Tips

To ace the interview for a Melter Clerk position, consider the following tips:

1. Research the industry and company

Familiarize yourself with the metals industry, melting processes, and the specific company you’re applying to. This knowledge will help you understand the role and demonstrate your interest.

- Visit the company’s website to learn about their products, services, and culture.

- Read industry publications and attend webinars to stay updated on the latest trends and technologies.

2. Highlight your technical skills

Emphasize your experience and proficiency in melting processes, quality control techniques, and equipment maintenance. Quantify your accomplishments with specific examples.

- Discuss your experience in operating and troubleshooting melting furnaces.

- Provide examples of successful quality control measures you’ve implemented.

3. Demonstrate your problem-solving abilities

Melter Clerks often encounter unexpected challenges. Showcase your ability to identify and resolve problems effectively.

- Share an experience where you faced a furnace malfunction and describe the steps you took to solve it.

- Explain how you troubleshoot and repair equipment issues.

4. Emphasize safety awareness

Safety is paramount in melting operations. Highlight your understanding and commitment to safety protocols.

- Describe your experience in following safety regulations and maintaining a safe work environment.

- Explain how you prioritize safety in all aspects of your work.

Next Step:

Now that you’re armed with the knowledge of Melter Clerk interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Melter Clerk positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini