Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Production Control Expediter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

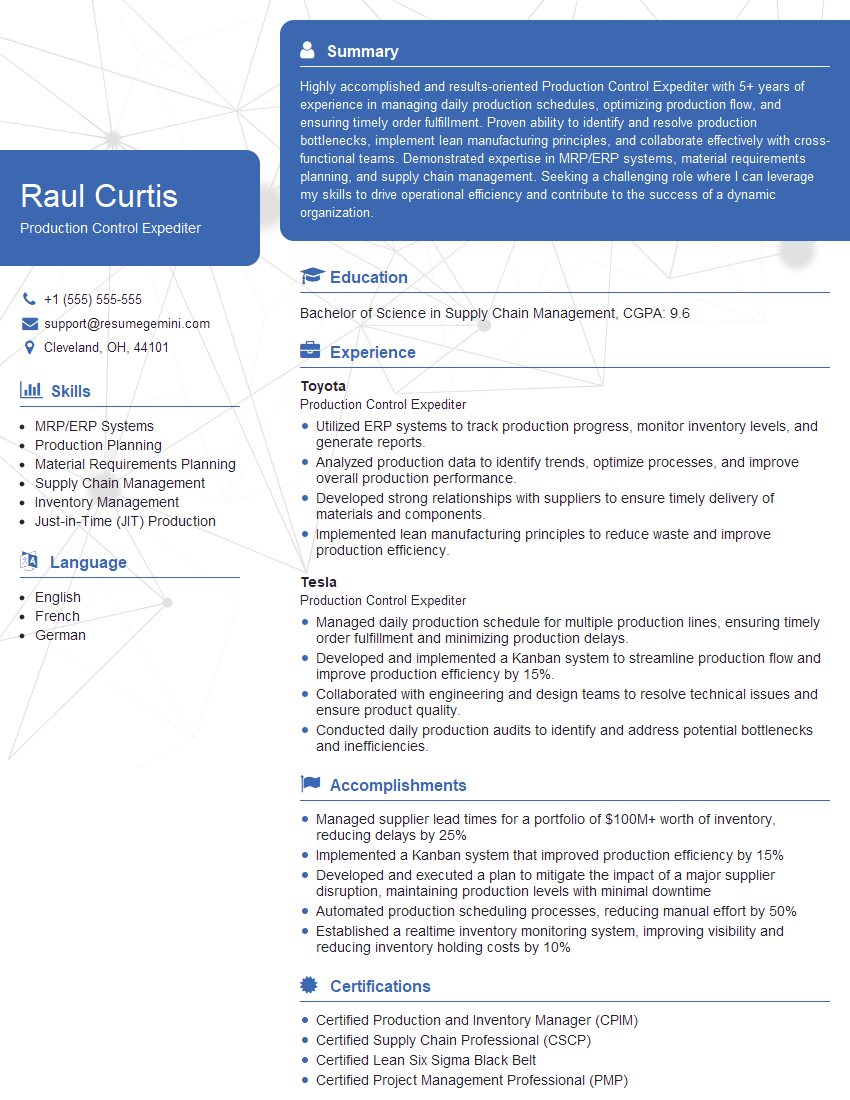

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Control Expediter

1. What is the role of a Production Control Expediter?

As a Production Control Expediter, my primary responsibility would be to ensure the smooth and efficient flow of production processes. This involves coordinating with various departments, monitoring progress, and resolving any issues that may arise.

- Coordinate with production, engineering, and purchasing departments to streamline production processes.

- Monitor production progress and identify potential bottlenecks or delays.

- Analyze production data and implement corrective actions to enhance efficiency and productivity.

- Resolve any issues or discrepancies that arise during the production process.

- Maintain accurate records and provide regular updates on production status to stakeholders.

2. How do you prioritize tasks and manage multiple projects simultaneously?

Prioritizing tasks effectively is crucial to managing multiple projects. I use a combination of techniques to ensure that the most critical tasks are addressed first.

Time-Sensitive Projects

- Identify projects or tasks with urgent deadlines and prioritize them accordingly.

- Break large projects into smaller, manageable tasks to make them less overwhelming.

Resource Allocation

- Assess the resources available and allocate them effectively to different projects.

- Collaborate with team members to delegate tasks and responsibilities based on their capabilities.

Regular Reviews

- Conduct regular reviews of project progress and adjust priorities as needed.

- Identify any potential overlaps or conflicts and proactively address them.

3. What is your experience in using MRP (Material Requirements Planning) systems?

I have extensive experience in utilizing MRP systems in various production environments. I am proficient in:

- Analyzing production plans and forecasting material requirements.

- Generating purchase orders and managing supplier relationships.

- Monitoring inventory levels and optimizing stock replenishment.

- Synchronizing production schedules with material availability.

- Identifying and resolving material shortages and surpluses.

4. How do you handle production delays?

- Assess the cause: Determine the root cause of the delay, whether it’s due to material shortages, equipment failures, or other factors.

- Communicate promptly: Inform stakeholders about the delay, providing clear details and the anticipated impact on production schedules.

- Replan and prioritize: Adjust production schedules and reprioritize tasks to minimize the impact of the delay.

- Find alternative solutions: Explore alternative suppliers or production methods to overcome material shortages or equipment issues.

- Monitor and track progress: Regularly monitor the situation and track progress to ensure that delays are minimized and production is back on track.

5. What are your strengths and weaknesses as a Production Control Expediter?

Strengths

- Strong analytical and problem-solving skills.

- Excellent communication and interpersonal skills.

- Proficient in using MRP and other production software.

- Proven ability to manage multiple projects simultaneously.

- Highly organized and detail-oriented.

Weaknesses

- I tend to be a perfectionist, which can sometimes lead to delays if I don’t manage my time effectively.

- I can be impatient when dealing with unforeseen challenges, but I am always willing to learn and improve.

6. How do you stay up-to-date on the latest production control technologies?

- Attend industry conferences and workshops: Stay informed about technological advancements and best practices by participating in industry events.

- Read industry publications and online resources: Keep up with the latest trends and developments through trade journals, white papers, and online articles.

- Network with professionals: Connect with other production control specialists and exchange ideas to learn about new technologies and approaches.

- Research and evaluate new software: Explore and evaluate emerging software solutions that can enhance production control processes.

- Participate in training and certification programs: Enhance your skills and knowledge through formal training and certification programs offered by industry organizations.

7. How do you ensure accuracy and maintain quality in production processes?

- Establish clear standards: Define and communicate clear quality standards and specifications for all production processes.

- Implement quality control measures: Implement regular inspections, testing, and monitoring procedures to ensure that products meet specifications.

- Empower employees: Train and empower employees to identify and resolve quality issues promptly.

- Use data to identify trends: Analyze production data to identify areas for improvement and eliminate potential quality problems.

- Seek continuous improvement: Regularly review and refine production processes to enhance quality and efficiency.

8. How do you measure and track production performance?

- Define key performance indicators (KPIs): Establish specific KPIs that measure the effectiveness and efficiency of production processes.

- Collect and analyze data: Gather data on production rates, downtime, material usage, and other relevant metrics.

- Monitor progress regularly: Track performance against KPIs and identify areas where improvements can be made.

- Provide feedback and make adjustments: Share performance results with stakeholders and implement necessary adjustments to optimize production processes.

- Use technology for tracking: Leverage production control software or other tools to automate data collection and provide real-time insights into performance.

9. How do you manage and motivate a team of production workers?

Communication

- Communicate clear expectations, goals, and instructions to the team.

- Provide regular feedback and updates on progress.

Recognition and Appreciation

- Recognize and reward employees for their achievements and contributions.

- Create a positive and supportive work environment.

Empowerment

- Empower employees to make decisions and take ownership of their tasks.

- Encourage teamwork and collaboration.

10. What are your career goals and aspirations in production control?

My career goal is to continuously contribute to the success of manufacturing organizations by optimizing production processes and enhancing efficiency. I aspire to take on leadership roles within production control, where I can leverage my skills to drive innovation and deliver exceptional results.

- Lead production control teams and implement best practices.

- Develop and implement strategies to improve production efficiency and reduce costs.

- Collaborate with other departments to ensure seamless integration of production processes.

- Stay abreast of industry advancements and embrace emerging technologies to enhance production capabilities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Control Expediter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Control Expediter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Production Control Expediter plays a pivotal role in ensuring smooth production operations by maintaining a steady flow of materials, parts, and components. Their primary responsibilities include:

1. Order Processing and Scheduling

Expedite the processing and scheduling of purchase orders and internal production orders.

- Analyze orders, identify potential bottlenecks, and devise strategies to mitigate delays.

- Coordinate with suppliers, vendors, and internal departments to establish realistic delivery timelines.

2. Inventory Management

Maintain accurate inventory records, track stock levels, and initiate replenishment orders as needed.

- Monitor inventory levels and identify items with low stock or high demand.

- Collaborate with Purchasing and Warehouse departments to ensure timely procurement and delivery of materials.

3. Production Monitoring and Control

Monitor production progress, identify potential problems, and take corrective actions promptly.

- Track production schedules, monitor equipment performance, and identify any deviations from planned timelines.

- Resolve production issues, coordinate with maintenance personnel to address equipment breakdowns, and implement contingency plans to minimize disruptions.

4. Material Expediting

Proactively expedite the delivery of critical materials, parts, and components to ensure timely production.

- Follow up with suppliers and vendors to track order status, identify delays, and negotiate expedited delivery.

- Coordinate with production teams to identify and prioritize materials based on criticality and production schedule.

5. Communication and Reporting

Communicate effectively with internal and external stakeholders to provide regular updates on production status and identify any roadblocks.

- Provide regular progress reports to management, production teams, and external customers.

- Identify and communicate potential problems, delays, and corrective actions to relevant parties.

Interview Tips

To ace the Production Control Expediter interview, candidates should prepare thoroughly and demonstrate their knowledge, skills, and enthusiasm for the role. Here are some tips to help them succeed:

1. Research the Company and Position

Candidates should research the company’s industry, business model, and production processes. They should also review the job description carefully to understand the specific requirements and responsibilities of the role.

2. Highlight Relevant Experience and Skills

Candidates should focus on highlighting their experience in production control, inventory management, and order processing. They should also emphasize their ability to schedule, monitor, and expedite production activities effectively.

3. Quantify Accomplishments

When discussing their past experiences, candidates should provide specific examples and quantify their accomplishments. For instance, they could mention how they reduced production lead times by 10% or improved inventory accuracy by 15%.

4. Demonstrate Problem-Solving Abilities

Candidates should be prepared to discuss how they handle problems and unexpected challenges in a production environment. They should provide examples of situations where they identified and resolved production issues, bottlenecks, or material shortages.

5. Emphasize Communication and Interpersonal Skills

Production Control Expediters need to communicate effectively with various stakeholders, including suppliers, vendors, production teams, and management. Candidates should emphasize their communication skills and ability to build strong relationships with colleagues and external partners.

6. Prepare for Common Interview Questions

Candidates should prepare for common interview questions related to their experience, skills, and understanding of production control principles. Some examples include:

- Tell me about your experience in production control and inventory management.

- How do you prioritize production orders and ensure timely delivery of critical materials?

- Describe a situation where you successfully resolved a major production problem.

- How do you communicate effectively with internal and external stakeholders to keep them updated on production progress?

- What are your key strengths and weaknesses as a Production Control Expediter?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Production Control Expediter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Production Control Expediter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.