Are you gearing up for an interview for a Retort Load Expediter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Retort Load Expediter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

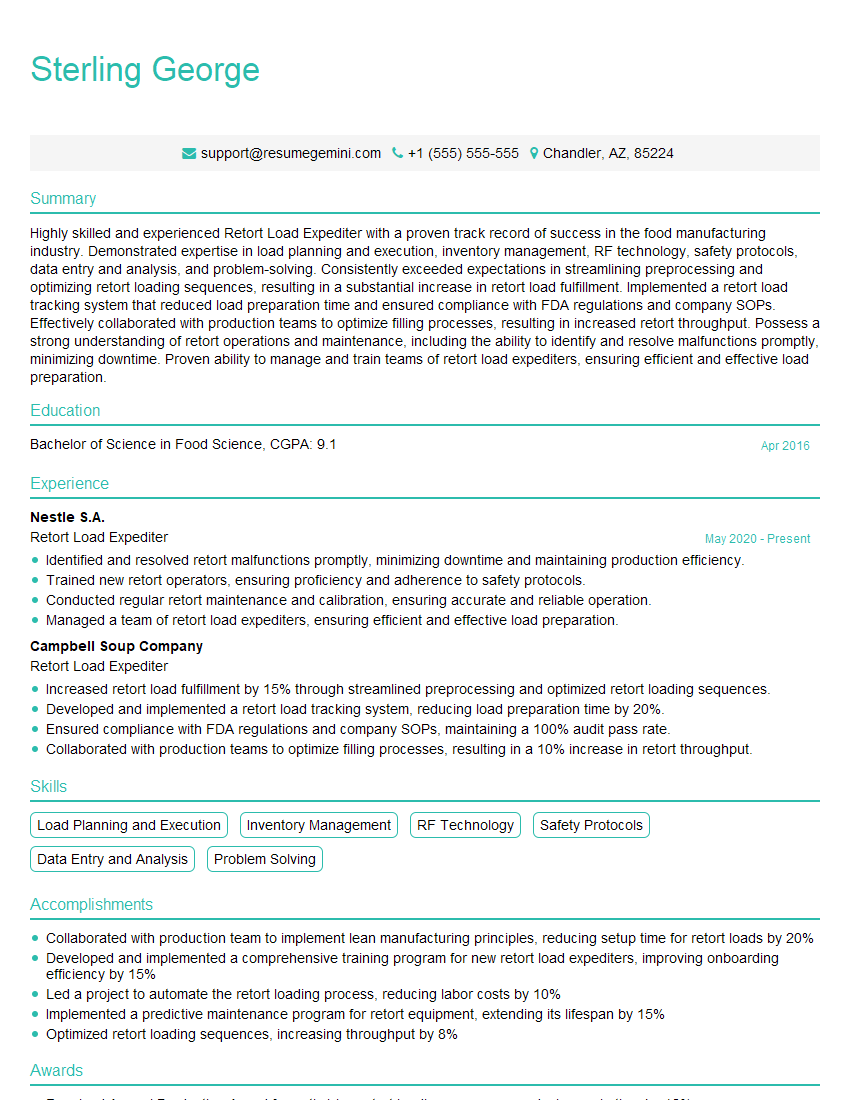

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Retort Load Expediter

1. what are the standard operating procedures you follow when loading a retort?

The standard operating procedures (SOPs) I follow when loading a retort include:

- Inspecting the retort and its components for any damage or wear.

- Ensuring that the retort is clean and free of any foreign objects.

- Loading the retort with the product to be processed, following the specified loading pattern.

- Closing the retort door and securing it properly.

- Connecting the retort to the appropriate utilities (e.g., steam, water, air).

- Starting the retort cycle and monitoring it closely throughout the process.

- Unloading the retort and inspecting the product for any damage or contamination.

- Cleaning and sanitizing the retort after use.

2. What are the critical control points (CCPs) in the retort process?

HACCP Principles

- Conduct a hazard analysis to identify potential hazards associated with the process.

- Determine the critical control points (CCPs) at which control measures can be applied to prevent or eliminate hazards.

- Establish critical limits for each CCP, which are the acceptable ranges for the process parameters.

- Monitor the CCPs and take corrective action when critical limits are exceeded.

- Verify that the CCPs are operating effectively and make adjustments as needed.

- Document and maintain records of CCP monitoring and corrective actions.

Specific CCPs in Retort Process

- Retort temperature and pressure.

- Retort cooling rate.

- Product fill weight.

- Container integrity.

- Retort process time.

3. How do you calculate the thermal process value (F0) for a retort process?

The thermal process value (F0) is a measure of the lethality of a retort process. It is calculated using the following formula:

F0 = ∫10min0min 10(T-Tref)/z dt

where:

- T is the temperature at any given time during the process

- Tref is the reference temperature (usually 250°F or 121°C)

- z is the z-value of the target microorganism

- dt is the time increment

The F0 value is expressed in minutes and represents the equivalent amount of time that the product would have to be exposed to a temperature of 250°F (121°C) to achieve the same level of lethality.

4. What are the different types of retort systems?

- Vertical retort systems are used for processing products in vertical containers, such as jars, bottles, and cans. They are typically used for high-acid products.

- Horizontal retort systems are used for processing products in horizontal containers, such as pouches and flexible bags. They are typically used for low-acid products.

- Hydrostatic retort systems use water pressure to create a uniform temperature distribution within the retort. They are typically used for processing large volumes of product.

- Agitation retort systems use agitation to create a more uniform temperature distribution within the retort. They are typically used for processing viscous products.

5. What are the advantages and disadvantages of using aseptic processing?

Advantages

- Products can be stored at ambient temperatures for extended periods of time.

- Products are free of spoilage microorganisms, which eliminates the need for preservatives.

- Aseptic processing can be used to produce a wide variety of products, including beverages, dairy products, and sauces.

Disadvantages

- Aseptic processing is more expensive than traditional processing methods.

- Aseptic processing requires specialized equipment and training.

- Aseptic processing can be more time-consuming than traditional processing methods.

6. What is the difference between a commercial and a pilot-scale retort?

- Commercial retorts are large, production-scale retorts that are used to process large volumes of product.

- Pilot-scale retorts are small, laboratory-scale retorts that are used to develop and test retort processes.

Pilot-scale retorts are typically used to determine the optimal retort temperature, time, and pressure for a particular product. They can also be used to test the effects of different packaging materials and container sizes.

7. What are the most common problems that can occur during retort processing?

- Underprocessing, which occurs when the product is not exposed to a sufficient amount of heat to kill all of the microorganisms

- Overprocessing, which occurs when the product is exposed to too much heat, which can damage the product and its nutritional value

- Container integrity problems, which can occur if the container is damaged during processing, allowing microorganisms to enter the product

- Equipment malfunctions, which can occur if the retort is not properly maintained or operated

8. What are the safety precautions that must be followed when operating a retort?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Do not operate a retort that is not properly maintained or calibrated.

- Never open a retort door while it is under pressure.

- Be aware of the potential for steam burns and other hazards when operating a retort.

- Follow all written procedures and safety protocols.

9. How do you troubleshoot a retort that is not heating properly?

- Check the power supply to the retort.

- Check the retort’s heating element for any damage.

- Check the retort’s thermostat for proper operation.

- Check the retort’s pressure gauge for proper operation.

- Check the retort’s water supply for any leaks.

If you are unable to troubleshoot the problem yourself, contact a qualified technician.

10. What are the latest trends in retort technology?

- The use of radio frequency (RF) heating to reduce processing time and energy consumption.

- The use of ohmic heating to improve heat transfer and reduce processing time.

- The development of new retort control systems to improve process accuracy and efficiency.

- The use of computer modeling to optimize retort processes.

- The development of new packaging materials that are more resistant to heat and pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Retort Load Expediter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Retort Load Expediter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Retort Load Expediters play a crucial role in ensuring the efficient and timely processing of food products in retort cookers.

1. Load and Unload Retort Cookers

The primary responsibility of a Retort Load Expediter is to load and unload retort cookers with food products.

- Load products into the retort cooker according to established procedures.

- Unload processed products from the retort cooker and inspect them for quality.

2. Monitor Retort Cooking Process

Retort Load Expediters are responsible for monitoring the retort cooking process to ensure that it meets the required temperature, pressure, and time parameters.

- Monitor temperature, pressure, and time parameters throughout the cooking cycle.

- Record process data and maintain accurate logs.

3. Maintain Retort Cookers and Equipment

To ensure proper functioning and safety, Retort Load Expediters are responsible for maintaining retort cookers and related equipment.

- Clean and maintain retort cookers and equipment.

- Perform minor repairs and calibrate equipment as needed.

4. Adhere to Safety Procedures

Retort Load Expediters must adhere to strict safety procedures to protect themselves and others in the workplace.

- Follow all safety protocols and wear appropriate personal protective equipment (PPE).

- Handle heavy equipment with care and follow proper lifting techniques.

Interview Tips

Preparing for an interview for a Retort Load Expediter position requires a thorough understanding of the role and the industry. Here are some tips to help candidates ace the interview:

1. Research the Company and Industry

Research the company you are interviewing with, their products, and the industry as a whole. This will demonstrate your interest and knowledge of the field.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are relevant to the Retort Load Expediter role. Quantify your accomplishments and use specific examples to illustrate your abilities.

- Highlight your experience in loading and unloading retort cookers, monitoring the cooking process, and maintaining equipment.

- Provide examples of how you have followed safety protocols and ensured a safe work environment.

3. Demonstrate a Strong Work Ethic

Retort Load Expediters are responsible for ensuring the smooth and efficient operation of the retort cooking process. Emphasize your strong work ethic and commitment to quality.

- Describe your ability to work independently and as part of a team.

- Share examples of how you have gone above and beyond to meet production goals.

4. Prepare for Common Interview Questions

There are several common interview questions that candidates should be prepared for. Practice answering these questions concisely and professionally.

- Tell me about yourself and your experience.

- Why are you interested in this role?

- What are your strengths and weaknesses?

- How do you handle stress and pressure?

5. Ask Questions at the End

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Prepare questions that demonstrate your understanding of the role and the company.

- Ask about the company’s safety protocols and quality standards.

- Inquire about opportunities for professional development and advancement.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Retort Load Expediter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.