Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Biodiesel Plant Manager position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

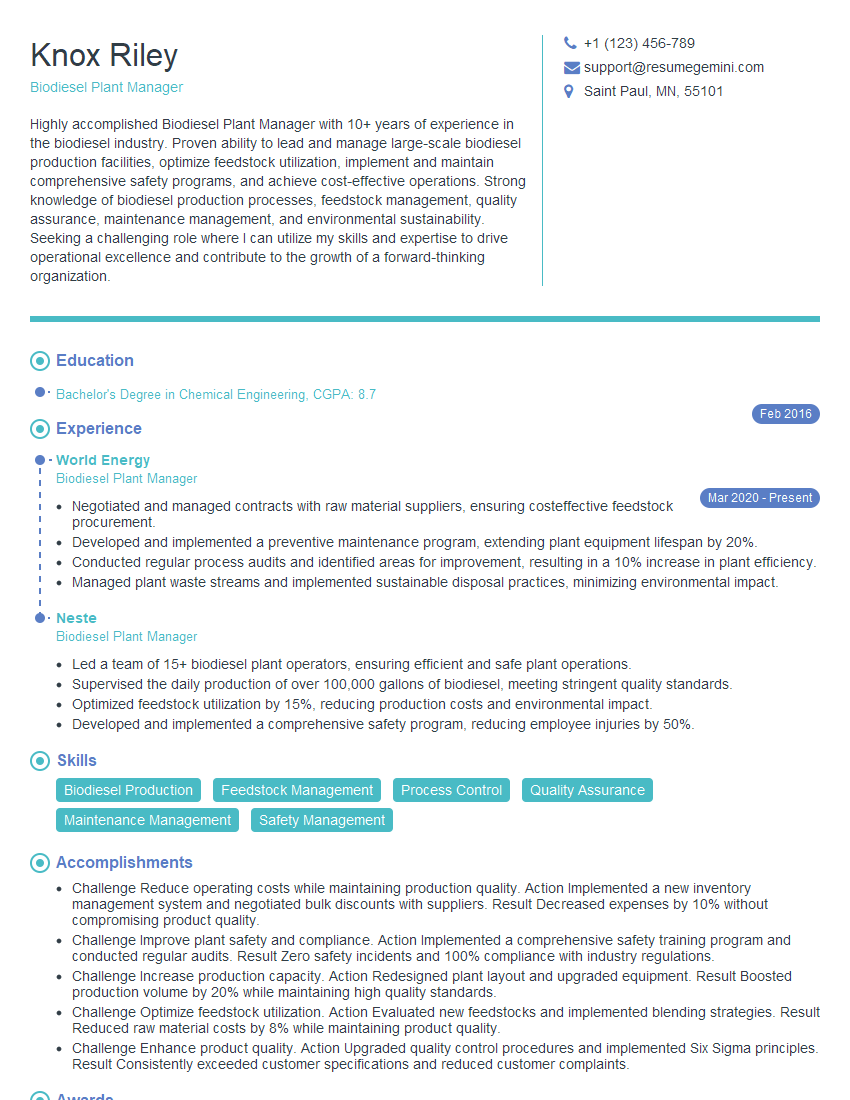

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Biodiesel Plant Manager

1. What are the key performance indicators (KPIs) for a biodiesel plant, and how do you monitor and track them?

- Production output (volume of biodiesel produced per unit of time)

- Feedstock utilization efficiency (amount of biodiesel produced per unit of feedstock consumed)

- Energy efficiency (amount of energy required to produce a unit of biodiesel)

- Yield (amount of biodiesel produced relative to the theoretical maximum)

- Quality (adherence to specifications, such as cetane number, acid number, and sulfur content)

- Equipment uptime (percentage of time that production equipment is operational)

- Safety (number and severity of accidents and incidents)

- Environmental compliance (adherence to regulations governing emissions, waste disposal, and water usage)

2. Describe the different types of feedstocks that can be used for biodiesel production, and discuss their advantages and disadvantages.

Vegetable oils

- Advantages: Renewable, environmentally friendly, high yield

- Disadvantages: High cost, limited availability, competition with food production

Animal fats

- Advantages: Lower cost than vegetable oils, readily available

- Disadvantages: Lower yield than vegetable oils, potential for contamination

Waste oils

- Advantages: Low cost, environmentally friendly

- Disadvantages: Lower yield than vegetable oils, potential for contamination

3. Discuss the different technologies used for biodiesel production, and explain the advantages and disadvantages of each.

Transesterification

- Advantages: Simple process, high yield, low cost

- Disadvantages: Requires high-quality feedstocks, produces glycerol as a byproduct

Hydrolysis

- Advantages: Can use low-quality feedstocks, produces less glycerol

- Disadvantages: More complex process, lower yield, higher cost

Enzymatic transesterification

- Advantages: Uses enzymes as catalysts, produces high-quality biodiesel

- Disadvantages: Slow process, higher cost

4. Discuss the quality control procedures that are essential for biodiesel production.

- Feedstock quality control: Ensuring that the feedstocks meet the required specifications

- Process control: Monitoring and controlling the process parameters to ensure optimal conditions for biodiesel production

- Product quality control: Testing the biodiesel to ensure that it meets the required specifications

5. What are the safety hazards associated with biodiesel production, and how can they be mitigated?

- Fire and explosion hazard: Biodiesel is flammable, and the production process involves the use of flammable solvents

- Chemical hazard: Biodiesel production involves the use of corrosive chemicals, such as lye and methanol

- Physical hazard: Biodiesel production involves the use of heavy equipment, which can pose a crushing or cutting hazard

- Mitigation measures: Use of fire-resistant materials, proper ventilation, training of employees, use of personal protective equipment

6. What are the environmental impacts of biodiesel production, and how can they be minimized?

- Emissions: Biodiesel production can emit greenhouse gases, such as carbon dioxide and nitrous oxide

- Water pollution: Biodiesel production can generate wastewater, which can contain pollutants, such as oil and grease

- Land use: Biodiesel production requires land for feedstock cultivation

- Mitigation measures: Use of renewable energy sources, wastewater treatment, sustainable land use practices

7. What are the current trends and future prospects for the biodiesel industry?

- Growing demand for biodiesel due to concerns about climate change and energy security

- Development of new technologies for biodiesel production, such as enzymatic transesterification and hydrothermal liquefaction

- Expansion of biodiesel production capacity in developing countries

8. What are the challenges facing the biodiesel industry, and how can they be overcome?

- Feedstock availability and cost

- Competition from other renewable fuels, such as ethanol

- Regulatory hurdles

- Overcoming challenges: Research and development of new feedstocks, policy support for biodiesel production, investment in infrastructure

9. What are the key qualities and skills that you believe are essential for a successful Biodiesel Plant Manager?

- Technical expertise in biodiesel production

- Strong leadership and management skills

- Excellent communication and interpersonal skills

- Ability to work independently and as part of a team

- Commitment to safety and environmental sustainability

10. What motivates you to pursue a career as a Biodiesel Plant Manager?

- Passion for renewable energy and sustainability

- Desire to make a positive impact on the environment

- Interest in the technical challenges of biodiesel production

- Opportunity to lead a team and contribute to the success of a growing industry

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Biodiesel Plant Manager.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Biodiesel Plant Manager‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Biodiesel Plant Manager has overall responsibility for the operation of a biodiesel plant, ensuring efficient production, quality control, safety compliance, and environmental sustainability.

1. Production Management

Oversees all aspects of biodiesel production, including feedstock acquisition, process optimization, and quality control.

- Develop and implement production plans to meet demand and minimize costs.

- Supervise and train production staff to ensure adherence to safety protocols.

2. Quality Control

Ensures the production of high-quality biodiesel that meets industry standards and customer specifications.

- Establish and maintain quality control systems throughout the production process.

- Conduct regular testing and analysis to monitor product quality and identify areas for improvement.

3. Safety Compliance

Maintains a safe and compliant work environment by enforcing safety regulations and implementing risk mitigation strategies.

- Develop and implement safety protocols and training programs for employees.

- Conduct regular safety inspections and audits to identify and address potential hazards.

4. Environmental Sustainability

Promotes environmental sustainability by minimizing waste, reducing emissions, and implementing sustainable practices.

- Develop and implement environmental management systems to comply with regulations and reduce the plant’s environmental impact.

- Monitor emissions and implement strategies to reduce greenhouse gases and other pollutants.

Interview Tips

Preparing thoroughly for a Biodiesel Plant Manager interview is crucial to demonstrate your expertise and make a lasting impression.

1. Research the Company and Industry

- Learn about the specific company’s values, mission, and history.

- Research the biodiesel industry, including current trends, technologies, and market conditions.

2. Highlight Relevant Experience and Skills

- Emphasize your experience in biodiesel production, quality control, safety management, or environmental sustainability.

- Quantify your accomplishments using specific metrics, such as production efficiency improvements or waste reduction.

3. Prepare for Technical Questions

- Practice answering questions about biodiesel production processes, quality control methods, and environmental regulations.

- Be prepared to discuss your approach to problem-solving and decision-making in a technical environment.

4. Demonstrate Leadership and Communication Skills

- Highlight your ability to lead and motivate a team in a fast-paced industrial setting.

- Emphasize your excellent communication skills, both written and verbal, as you will need to interact with stakeholders within and outside the organization.

Next Step:

Now that you’re armed with the knowledge of Biodiesel Plant Manager interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Biodiesel Plant Manager positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini