Are you gearing up for an interview for a Gas Well Drilling Manager position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Gas Well Drilling Manager and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

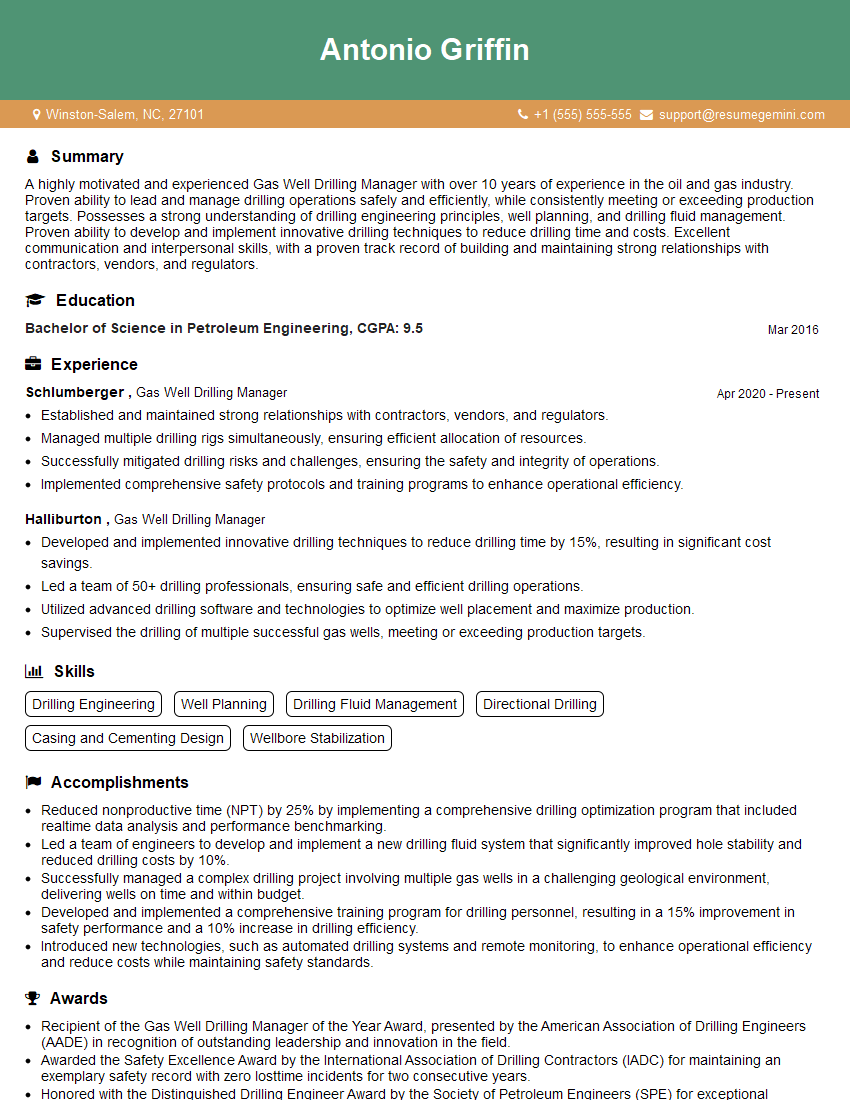

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Well Drilling Manager

1. How do you plan and execute a successful gas well drilling operation?

- Thorough planning and preparation, including geological and geophysical studies, environmental impact assessments, and drilling program design.

- Rig selection and mobilization, considering drilling depth, wellbore trajectory, and formation characteristics.

- Drill bit and bottom hole assembly (BHA) selection to optimize drilling efficiency and hole stability.

- Drilling fluid and cementing program design to ensure wellbore stability, prevent fluid loss, and protect formations.

- Real-time data monitoring and analysis to identify and mitigate drilling hazards and optimize operations.

- Effective communication and coordination with drilling crew, rig contractors, and other stakeholders.

- Compliance with industry standards, regulations, and safety protocols throughout the operation.

2. How do you manage and mitigate drilling risks, such as lost circulation, stuck pipe, and blowouts?

subheading of the answer

- Conduct thorough risk assessments and implement preventive measures.

- Monitor drilling parameters closely and adjust operations accordingly.

- Use appropriate drilling fluids and additives to control formation pressure and prevent lost circulation.

- Inspect and maintain drilling equipment regularly to minimize the risk of stuck pipe.

- Establish clear emergency response plans and train crew members on blowout prevention.

- Coordinate with well control specialists and have necessary equipment on standby.

- Foster a culture of safety and adherence to best practices.

subheading of the answer

- Have a comprehensive understanding of well control techniques and equipment.

- Conduct regular drills and simulations to prepare for emergency situations.

- Promote open communication and encourage crew members to report any potential hazards.

- Continuously evaluate and improve safety procedures and protocols.

3. How do you optimize drilling efficiency while ensuring borehole integrity?

- Use high-quality drilling bits and BHA to minimize drilling time and improve borehole quality.

- Optimize drilling parameters, such as weight on bit and rotary speed, to maximize penetration rates.

- Monitor and manage drilling fluid properties to ensure hole stability and prevent formation damage.

- Use directional drilling techniques to accurately steer the wellbore and minimize the risk of borehole deviation.

- Perform casing and liner operations timely to protect the borehole and prevent collapse.

4. How do you evaluate drilling performance and identify areas for improvement?

- Track and analyze drilling parameters, such as penetration rates, torque, and mud flow rates.

- Compare actual performance to planned targets and industry benchmarks.

- Identify deviations from expected performance and investigate the underlying causes.

- Implement corrective actions and modifications to improve drilling efficiency and wellbore quality.

5. How do you manage a team of drilling professionals and maintain effective communication?

- Establish clear roles and responsibilities for team members.

- Foster open communication and encourage input from all team members.

- Provide regular updates and briefings on drilling progress and potential challenges.

- Create a positive and supportive work environment to promote teamwork and collaboration.

6. How do you stay up-to-date with the latest advancements in drilling technology and industry best practices?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Participate in online forums and discussion groups.

- Engage with vendors and drilling experts to learn about new technologies and equipment.

7. How do you ensure compliance with environmental regulations and protect the environment during drilling operations?

- Conduct environmental impact assessments and develop mitigation plans.

- Use environmentally friendly drilling fluids and chemicals.

- Manage waste streams properly, including cuttings, drilling fluids, and produced water.

- Implement erosion control measures to prevent soil loss.

- Monitor air and water quality during drilling operations.

8. How do you handle unforeseen geological or drilling challenges and make quick decisions under pressure?

- Consult with geologists and drilling engineers to assess the situation and evaluate options.

- Consider the risks and benefits of different courses of action.

- Gather and analyze available data to make informed decisions.

- Communicate the decision to the drilling team and ensure proper execution.

- Monitor the situation closely and adjust the decision as needed.

9. How do you communicate technical information and drilling plans to non-technical stakeholders, such as management and investors?

- Use clear and concise language.

- Provide analogies and examples to simplify complex concepts.

- Use visual aids, such as charts and diagrams, to support explanations.

- Tailor the communication to the specific audience.

- Answer questions and provide additional information as needed.

10. How do you measure your success as a Gas Well Drilling Manager?

- Safe and successful drilling of gas wells.

- Meeting drilling targets, including depth, trajectory, and production goals.

- Minimizing drilling costs and maximizing operational efficiency.

- Ensuring compliance with all relevant regulations and standards.

- Maintaining a positive and productive work environment for the drilling team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Well Drilling Manager.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Well Drilling Manager‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Gas Well Drilling Manager is responsible for the overall planning, execution, and evaluation of gas well drilling operations. They work closely with a team of engineers, geologists, and other professionals to ensure that wells are drilled safely, efficiently, and in compliance with all applicable regulations.

1. Planning and Preparation

The manager must develop and implement a drilling plan that outlines the specific steps and procedures to be followed during the drilling process. They must also procure all of the necessary equipment and materials, and ensure that the drilling crew is properly trained and certified.

2. Drilling Operations

The manager is responsible for overseeing all aspects of the drilling operation, including the selection of drilling equipment, the monitoring of drilling progress, and the evaluation of drilling data. They must also make decisions regarding wellbore trajectory, casing design, and fluid selection.

3. Safety and Environmental Management

The manager must ensure that all drilling operations are conducted in a safe and environmentally responsible manner. They must comply with all applicable safety regulations and develop and implement a comprehensive safety plan. They must also monitor environmental impacts and take steps to minimize the risk of pollution.

4. Cost Control and Reporting

The manager is responsible for controlling the costs of drilling operations and ensuring that all expenses are properly documented. They must also prepare and submit regular reports to management on the progress of drilling operations and the status of the well.

Interview Tips

To prepare for an interview for a Gas Well Drilling Manager position, it is important to have a strong understanding of the key job responsibilities and to be able to demonstrate your experience and qualifications in these areas. Here are some tips to help you ace the interview:

1. Research the company and the position

Before the interview, take some time to learn about the company and the specific position you are applying for. This will help you to understand the company’s culture and values, and to tailor your answers to the interviewer’s questions.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in a clear and concise way, and make sure to highlight your relevant experience and qualifications.

3. Be prepared to discuss your experience in detail

The interviewer will likely ask you about your experience in gas well drilling, so be prepared to discuss your role and responsibilities in detail. Be able to provide specific examples of your accomplishments, and explain how your experience has prepared you for this position.

4. Ask questions

Asking questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions to ask the interviewer about the company, the position, and the team you would be working with.

Next Step:

Now that you’re armed with the knowledge of Gas Well Drilling Manager interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Gas Well Drilling Manager positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini