Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Puller position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

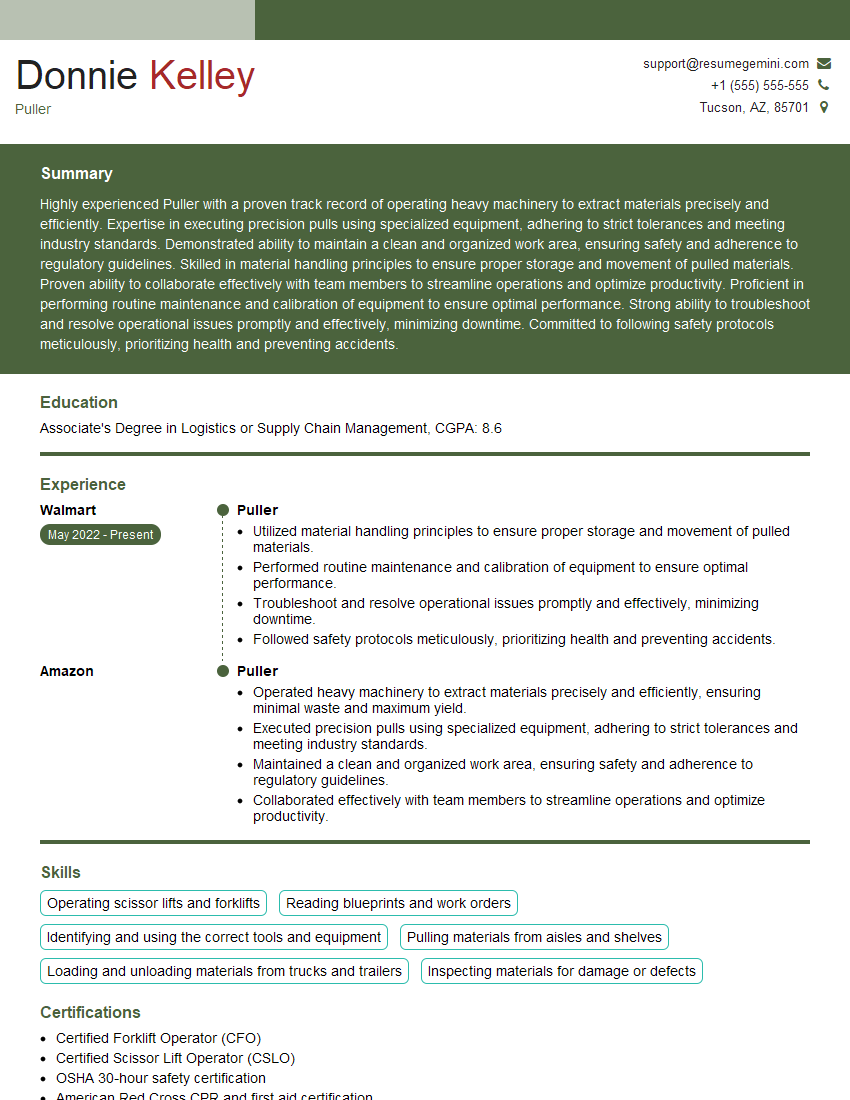

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Puller

1. How do you plan and prioritize your workload to ensure timely and efficient delivery?

- I begin by creating a prioritized task list based on urgency, importance, and deadlines.

- I utilize time management techniques like the Pomodoro Technique to stay focused and minimize distractions.

- I communicate regularly with stakeholders to ensure alignment and manage expectations.

- I leverage automation tools to streamline processes and free up time for more complex tasks.

- I constantly evaluate and adjust my approach to optimize efficiency and productivity.

2. Describe your experience in implementing and optimizing rigging systems for varied applications.

1: Planning and Design

- I conduct thorough site assessments to identify potential hazards and determine appropriate rigging solutions.

- I utilize industry-standard design software to create detailed plans that meet safety regulations and performance requirements.

Subheading 2: Installation and Commissioning

- I oversee the installation of rigging equipment and ensure it is assembled and tested according to manufacturer specifications.

- I perform load testing and inspections to verify the integrity and functionality of the system.

Subheading 3: Maintenance and Inspection

- I develop and implement maintenance schedules to ensure the longevity and safety of the rigging system.

- I conduct regular inspections to identify any potential issues or areas for improvement.

3. How do you ensure compliance with industry regulations and safety protocols when working with rigging equipment?

- I maintain a comprehensive understanding of industry regulations, codes, and standards.

- I actively participate in training programs and certifications to stay up-to-date with best practices.

- I conduct thorough risk assessments and implement appropriate mitigation measures.

- I ensure that all equipment is regularly inspected and certified.

- I foster a safety-first culture among my team and emphasize the importance of proper handling and maintenance.

4. How do you approach troubleshooting and resolving technical issues related to rigging equipment?

- I begin by identifying the symptoms and potential causes of the issue.

- I conduct thorough inspections and diagnostic testing to pinpoint the root cause.

- I research technical manuals and consult with industry experts to explore possible solutions.

- I implement appropriate repairs or adjustments based on the identified cause.

- I verify the effectiveness of the solution through testing and monitoring.

5. Describe your experience in working collaboratively with engineers, architects, and other professionals on rigging projects.

- I actively participate in project planning meetings and provide technical input.

- I collaborate with engineers to review designs and ensure feasibility.

- I work closely with architects to understand their design intent and translate it into practical rigging solutions.

- I maintain open communication channels and proactively address any queries or concerns.

- I foster a collaborative environment that values diverse perspectives and encourages knowledge sharing.

6. How do you stay abreast of advancements and emerging trends in the field of rigging and lifting?

- I attend industry conferences and workshops to stay informed about new technologies and methodologies.

- I subscribe to industry publications and online resources to access the latest research and best practices.

- I engage in ongoing professional development and pursue certifications to expand my knowledge and skills.

- I network with other professionals in the field and share ideas.

- I explore emerging technologies and evaluate their potential applicability to rigging and lifting operations.

7. Describe a challenging rigging project you have worked on and how you overcame the obstacles encountered.

- The project involved rigging a heavy piece of machinery in a confined space with limited access.

- I conducted a thorough site assessment and identified potential challenges, such as overhead obstructions and weight constraints.

- I developed a customized rigging plan that utilized specialized equipment and techniques.

- I coordinated with a team of skilled operators to safely and efficiently execute the rigging operation.

- I adapted to unexpected changes in conditions and found innovative solutions to overcome obstacles.

8. How do you handle situations where there are multiple stakeholders with conflicting requirements?

- I actively listen to the perspectives of all stakeholders and strive to understand their needs.

- I facilitate discussions to identify common ground and areas of compromise.

- I present clear and well-reasoned recommendations based on technical expertise and industry best practices.

- I work collaboratively to develop solutions that balance the interests of all parties.

- I maintain a professional and respectful demeanor throughout the process.

9. How do you prioritize safety and risk management in your approach to rigging operations?

- I conduct thorough risk assessments to identify potential hazards and develop mitigation strategies.

- I ensure that all equipment is regularly inspected and maintained to meet safety standards.

- I develop and implement safe work procedures that prioritize the well-being of workers and third parties.

- I train my team on safety protocols and ensure they have the necessary knowledge and skills.

- I actively monitor operations and intervene to address any unsafe practices.

10. What are your career goals and how do you see this role contributing to your professional development?

- I aspire to become a recognized leader in the rigging industry.

- This role will provide me with the opportunity to expand my technical expertise and gain exposure to complex projects.

- I am eager to contribute my skills and knowledge to the team and support the company’s growth.

- I believe that my passion for rigging and commitment to safety will make me a valuable asset to your organization.

- I am confident that this role will provide me with a strong foundation for my future career aspirations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Puller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Puller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Puller plays a vital role in supporting the smooth operations of a warehouse or manufacturing facility by handling and transporting materials efficiently. Key job responsibilities include:

1. Material Handling

Pullers are responsible for the safe and efficient movement of various materials within the warehouse or facility. This includes:

- Operating forklifts, pallet jacks, and other material handling equipment

- Loading and unloading materials

- Stacking and unstacking pallets

- Transferring materials between different areas of the warehouse or facility

2. Inventory Control

Pullers assist in maintaining accurate inventory records by:

- Scanning and tracking materials

- Verifying inventory levels

- Reporting discrepancies or shortages

3. Quality Control

Pullers help ensure the quality of materials by:

- Inspecting incoming materials for damage or defects

- Identifying and segregating damaged or defective materials

- Following quality control procedures

4. Safety and Compliance

Pullers prioritize safety in the workplace by:

- Adhering to safety regulations and guidelines

- Using equipment safely and properly

- Reporting any safety hazards or concerns

- Maintaining a clean and organized work area

Interview Tips

To ace an interview for a Puller position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This shows that you are genuinely interested in the role and have taken the time to learn about the organization.

- Visit the company’s website and social media pages.

- Read industry news and articles.

2. Highlight Relevant Skills and Experience

In your resume and interview, emphasize your skills and experience in material handling, inventory control, and safety. Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- If you have used material handling equipment in the past, describe your experience in detail, including the types of equipment you have operated.

- If you have experience in inventory management, highlight your knowledge of inventory systems and procedures.

3. Demonstrate Safety Awareness

Safety is paramount in a warehouse or manufacturing environment. Emphasize your commitment to safety by describing your understanding of safety protocols and your track record of working safely.

- Mention any safety certifications or training you have received.

- Provide examples of how you have identified and mitigated safety hazards in previous roles.

4. Prepare for Common Interview Questions

Be prepared to answer common interview questions related to the Puller role, such as:

- Tell me about your experience in material handling.

- How do you ensure accuracy in inventory management?

- What are your safety priorities in the workplace?

- How do you handle heavy or bulky materials safely?

5. Practice Your Answers

Practice your answers to the common interview questions mentioned above and any other questions you think you might be asked. This will help you feel more confident and prepared during the interview.

6. Dress Professionally and Arrive on Time

Make a positive first impression by dressing professionally and arriving on time for the interview. This shows that you respect the interviewer and the opportunity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Puller, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Puller positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.