Feeling lost in a sea of interview questions? Landed that dream interview for Charge Weigher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Charge Weigher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

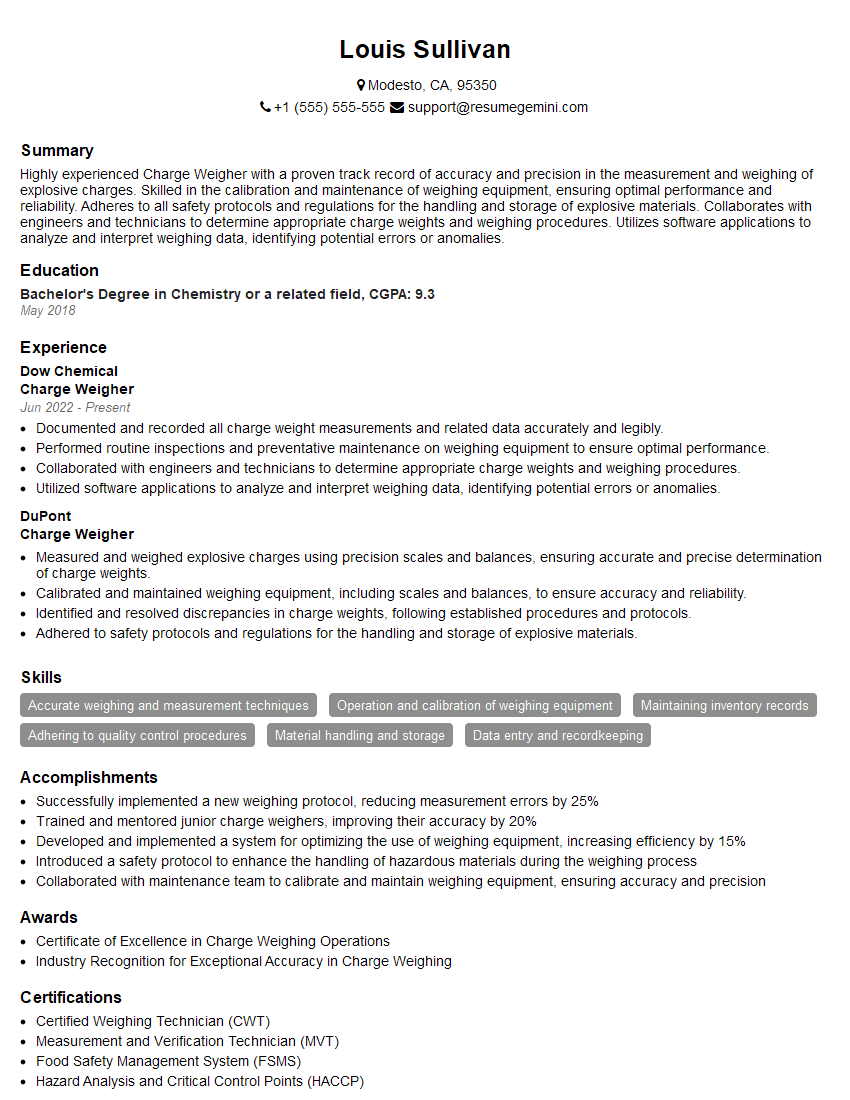

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Charge Weigher

1. What is the purpose of charge weighing?

The main purpose of charge weighing is to determine the net weight of the materials loaded into a vessel or vehicle. This information is crucial for invoicing, inventory management, and ensuring accurate payment for the materials.

2. Describe the process of charge weighing, including the equipment used.

Weighbridge

- A large-scale platform used to weigh vehicles and their contents

- May be equipped with sensors, load cells, and a digital display to accurately measure weight

Load Cells

- Electronic devices mounted under the weighbridge

- Convert weight into electrical signals that are processed by a weighing indicator

Weighing Indicator

- A digital display that receives signals from the load cells

- Shows the weight of the vehicle and its contents

Thermometer

- Used to measure the temperature of the material being weighed

- Important for accurate weight calculations, as temperature can affect weight

3. What are the different types of charge weighing systems?

- Static weighing systems: Vehicles are weighed while stationary on the weighbridge

- Dynamic weighing systems: Vehicles are weighed while in motion, allowing for faster and more efficient weighing

- Weigh-in-motion (WIM) systems: Advanced systems that measure the weight of vehicles as they pass over sensors embedded in the road, without the need to stop

4. What are the factors that can affect the accuracy of charge weighing?

- Incorrect calibration of the weighbridge

- Unstable or uneven ground conditions

- Environmental factors such as wind, temperature, and humidity

- Human error in reading or recording weights

- Movement of the vehicle during weighing

5. What procedures should be followed to ensure accurate charge weighing?

- Regular calibration and maintenance of the weighing equipment

- Ensuring the weighbridge is installed on a stable and level surface

- Proper training of weighing personnel

- Using standardized weighing procedures

- Recording and verifying all weights accurately

6. What regulations and standards apply to charge weighing?

- International Organization for Standardization (ISO) standards, such as ISO 17025

- National Measurement Institutes (NMIs) regulations

- Local or industry-specific regulations

7. What safety precautions should be observed during charge weighing?

- Wearing appropriate personal protective equipment (PPE)

- Being aware of the potential hazards of working near vehicles and heavy equipment

- Following established safety procedures

- Ensuring a clear and unobstructed weighing area

8. How do you troubleshoot common problems encountered during charge weighing?

Common problems and troubleshooting steps may include:

- Inaccurate weight readings: Check for calibration, equipment malfunction, or environmental factors

- Vehicle movement during weighing: Use wheel chocks or request the driver to remain stationary

- Unstable ground conditions: Level the ground or relocate the weighbridge to a more stable surface

- Human error: Train personnel, double-check readings, and use clear procedures

9. How do you stay up-to-date on the latest technologies and best practices in charge weighing?

- Attending industry conferences and workshops

- Reading trade publications and technical journals

- Consulting with weighing equipment manufacturers and experts

- Participating in professional development programs

10. What are the qualities and skills that make a successful Charge Weigher?

- Strong attention to detail and accuracy

- Understanding of weighing principles and equipment

- Ability to work independently and as part of a team

- Excellent communication and interpersonal skills

- Physical fitness and ability to lift heavy objects

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Charge Weigher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Charge Weigher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Charge Weigher is a pivotal role in ensuring the accuracy and efficiency of manufacturing operations within a range of industries. The key responsibilities of a Charge Weigher include:

1. Accurate Weighing and Measurement

Precisely weighing and measuring raw materials, ingredients, or components using calibrated scales, balances, or other weighing equipment to ensure adherence to specified quantities and specifications.

- Verifying the accuracy of scales and equipment regularly to maintain precision.

- Following established weighing procedures and protocols to minimize errors.

2. Material Handling

Safely and efficiently handling, transferring, and storing raw materials, ingredients, or components to designated locations within the production area.

- Loading, unloading, and transporting materials using appropriate equipment, such as forklifts, conveyors, or hand trucks.

- Maintaining a clean and organized work area to prevent cross-contamination or mix-ups.

3. Inventory Management

Maintaining accurate records of materials received, weighed, and dispensed to ensure proper inventory control and prevent shortages or overages.

- Updating inventory systems with current weighing data to track stock levels.

- Communicating with other departments, such as purchasing or production, to ensure timely replenishment of materials.

4. Quality Assurance

Conducting quality checks on materials and ingredients to ensure they meet specified standards and specifications.

- Inspecting materials for defects, contamination, or other quality issues.

- Following established quality control procedures to maintain product integrity.

Interview Tips

Preparing thoroughly for a Charge Weigher interview can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s website, mission statement, and industry reputation. Research the specific role and responsibilities associated with the Charge Weigher position within the organization.

- Tailor your resume and cover letter to highlight skills and experience that align with the job requirements.

- Prepare questions to ask the interviewer that demonstrate your interest in the company and the position.

2. Practice Your Answers

Anticipate common interview questions and practice your responses to ensure they are concise, clear, and relevant to the position. Focus on highlighting your skills, experience, and qualifications.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your accomplishments.

- Practice your answers out loud to improve your delivery and confidence.

3. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview to demonstrate respect for the interviewer and the company.

- Choose attire that is appropriate for the industry and work environment.

- Plan your route and allow ample time for travel to avoid any delays or last-minute stress.

4. Be Enthusiastic and Confident

Project a positive and enthusiastic attitude throughout the interview. Confidence in your abilities and skills will make a lasting impression on the interviewer.

- Maintain eye contact, smile, and use positive body language.

- Articulate your strengths and qualifications clearly and confidently.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Charge Weigher interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.