Feeling lost in a sea of interview questions? Landed that dream interview for Cane Weigher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cane Weigher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

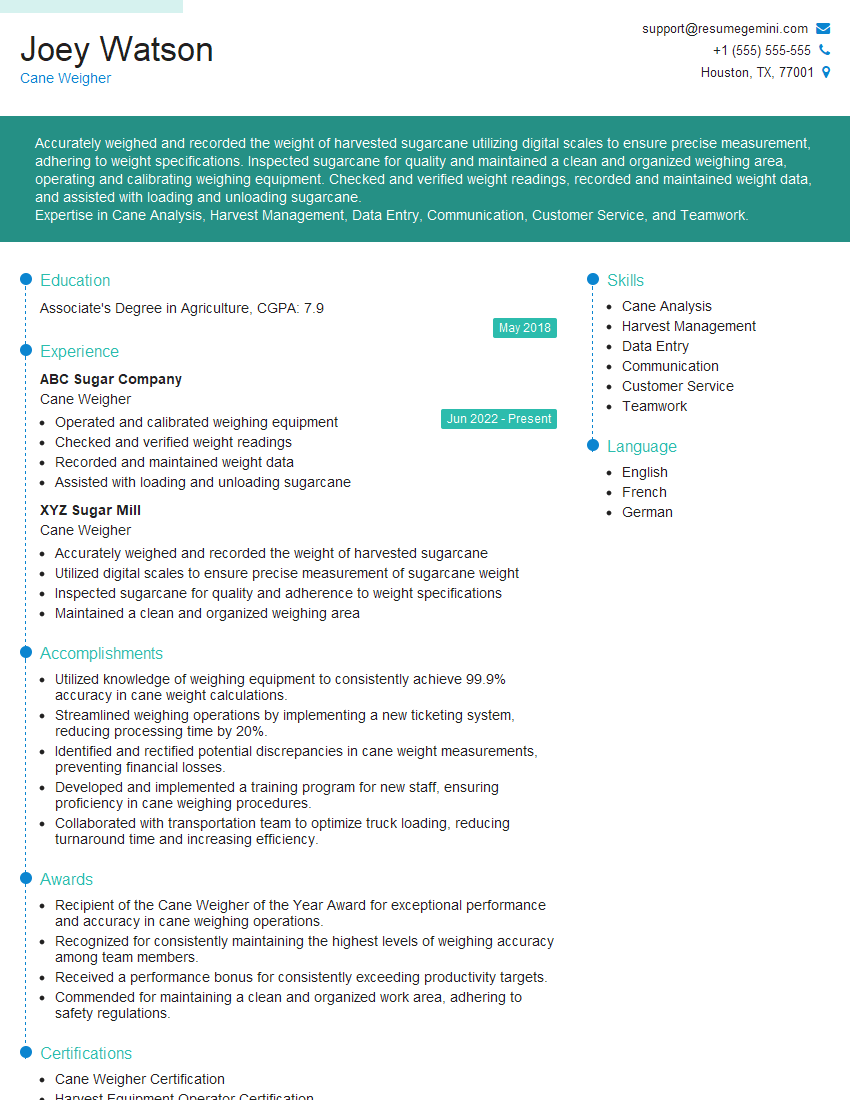

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cane Weigher

1. Explain the process of weighing cane trucks?

The process of weighing cane trucks involves several key steps:

- Truck arrival: When a cane truck arrives at the weighing station, the driver presents a weigh ticket to the weigher.

- Gross weighing: The truck is driven onto the weighbridge, and the weigher records the gross weight of the truck and its contents.

- Tare weighing: After the truck is unloaded, the driver moves it back onto the weighbridge for a tare weigh to determine the weight of the empty truck.

- Net weight calculation: The weigher subtracts the tare weight from the gross weight to calculate the net weight of the cane.

- Ticket issuance: The weigher prints a new weigh ticket showing the net weight and other relevant information and hands it to the driver.

2. What are the different types of weighbridges used for cane weighing?

Mechanical Weighbridges

- Lever weighbridges: Use a system of levers and weights to measure weight.

- Hydraulic weighbridges: Use hydraulic pressure to measure weight.

Electronic Weighbridges

- Strain gauge weighbridges: Use strain gauges to measure weight.

- Piezoelectric weighbridges: Use piezoelectric crystals to measure weight.

3. What factors can affect the accuracy of cane weighing?

- Calibration: Regular calibration is crucial to ensure accuracy.

- Environmental factors: Temperature fluctuations, wind, and vibration can affect readings.

- Operator error: Human errors in reading, recording, or computing weights can occur.

- Truck condition: Factors such as uneven tire pressure or uneven loading can impact accuracy.

- Weighbridge condition: Faulty or damaged weighbridges can provide inaccurate readings.

4. How do you ensure the safety of cane trucks during weighing?

- Clear instructions: Provide clear instructions to drivers before they drive onto the weighbridge.

- Safety barriers: Use barriers to prevent trucks from falling off the weighbridge.

- Proper lighting: Ensure adequate lighting for drivers to navigate safely.

- Emergency protocols: Establish emergency protocols in case of accidents or malfunctions.

- Driver visibility: Ensure drivers have good visibility of the weighing area.

5. What are the different methods of sampling cane for quality assessment?

- Grab sampling: A representative sample is taken manually from the truck.

- Mechanical sampling: A mechanical sampler automatically collects samples as the truck unloads.

- Composite sampling: Samples are collected from multiple locations and combined to form a representative sample.

- Random sampling: Samples are collected at random intervals during unloading.

6. How do you calibrate a weighbridge?

- Test weights: Use certified test weights to check the accuracy of the weighbridge.

- Load cells: Adjust the load cells to ensure they are providing accurate readings.

- Linearity test: Test the weighbridge’s accuracy over a range of weights.

- Documentation: Keep a record of all calibration procedures and results.

7. What are the common issues that can occur with weighbridges and how do you troubleshoot them?

- Zeroing errors: Check the zero point of the weighbridge and adjust as necessary.

- Drifting readings: Check the load cells and wiring for loose connections or damage.

- Inaccurate readings: Calibrate the weighbridge and check for environmental factors that may affect accuracy.

- Mechanical issues: Inspect the weighbridge’s mechanical components for damage or wear.

8. How do you maintain and clean a weighbridge?

- Regular inspection: Inspect the weighbridge regularly for any damage or wear.

- Cleaning: Clean the weighbridge deck and load cells to remove debris and dirt.

- Lubrication: Lubricate moving parts to ensure smooth operation.

- Load testing: Conduct periodic load tests to assess the weighbridge’s accuracy and functionality.

9. What safety precautions should be taken while operating a weighbridge?

- Wear appropriate safety gear: Wear safety shoes, gloves, and a high-visibility vest.

- Stay clear of moving vehicles: Keep a safe distance from trucks while they are on the weighbridge.

- Use proper lifting techniques: Lift heavy objects safely to avoid injuries.

- Be aware of surroundings: Pay attention to your surroundings and potential hazards.

- Report any issues: Immediately report any safety concerns or malfunctions to the supervisor.

10. How do you handle disputes or discrepancies in cane weighing?

- Listen to the driver’s concerns: Actively listen to the driver’s perspective and try to understand their point of view.

- Review records: Check the weighbridge records and previous weighings to identify any potential errors.

- Recalibrate the weighbridge: If necessary, recalibrate the weighbridge to ensure accuracy.

- Contact the supervisor: If the issue cannot be resolved, involve the supervisor for guidance and support.

- Maintain a professional demeanor: Remain calm and professional throughout the dispute resolution process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cane Weigher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cane Weigher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Cane Weigher

Cane Weighers play a crucial role in the sugar production process, ensuring accurate weighing and recording of sugarcane deliveries to the mill. Their primary responsibilities include:

1. Weighing and Recording Cane Deliveries

The Cane Weigher operates a weighbridge or other weighing device to determine the gross weight of incoming sugarcane trucks.

- Accurately weigh each truckload of sugarcane using a certified scale.

- Record the gross weight, tare weight, and net weight (weight of sugarcane excluding the truck) in a logbook or digital system.

2. Maintaining Weighing Equipment

Cane Weighers are responsible for the proper functioning of the weighing equipment.

- Perform daily checks of the weighbridge to ensure accuracy and calibration.

- Inspect and maintain weighing equipment, such as scales, indicators, and sensors.

- Report any equipment malfunctions or irregularities to the supervisor.

3. Collecting and Reporting Data

Cane Weighers gather and analyze data related to sugarcane deliveries.

- Collect data on truck numbers, delivery dates, and weights (gross, tare, and net).

- Calculate average weights and track trends in sugarcane deliveries.

- Prepare reports and provide data to supervisors, management, and other relevant parties.

4. Maintaining a Clean and Safe Work Environment

Cane Weighers are responsible for ensuring a safe and clean work area.

- Maintain a clean and organized weighing area, free from debris and hazards.

- Follow safety protocols and wear appropriate personal protective equipment (PPE).

- Report any safety concerns or incidents to the supervisor immediately.

Interview Tips for Cane Weigher Candidates

To ace an interview for a Cane Weigher position, it is essential to present a strong understanding of the role and demonstrate your relevant skills and experience. Here are some tips:

1. Research the Company and Position

Read about the sugar industry, the company’s history, and the specific requirements of the Cane Weigher position. This information will help you tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages.

- Read industry publications and articles.

- Review job descriptions and descriptions of similar positions.

2. Highlight Relevant Experience and Skills

Emphasize your experience in weighing operations, data collection, and customer service. Highlight your attention to detail, accuracy, and ability to work independently.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Provide examples of your ability to maintain accurate records, solve problems, and communicate effectively.

3. Prepare for Common Interview Questions

Review common interview questions related to the Cane Weigher role. Prepare thoughtful answers that demonstrate your knowledge, skills, and enthusiasm for the position.

- Why are you interested in this role?

- Tell me about your experience in weighing operations.

- How do you handle errors or discrepancies in weighing data?

- Describe your understanding of the sugar production process.

- What are your strengths and weaknesses as a Cane Weigher?

4. Be Enthusiastic and Professional

Show your passion for the sugar industry and your commitment to accuracy and efficiency. Dress professionally, arrive on time, and maintain a positive and enthusiastic attitude throughout the interview.

- Make eye contact, smile, and greet the interviewer confidently.

- Ask thoughtful questions to show your interest in the company and the position.

- Thank the interviewer for their time and follow up promptly after the interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cane Weigher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cane Weigher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.