Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tank Calibrator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tank Calibrator so you can tailor your answers to impress potential employers.

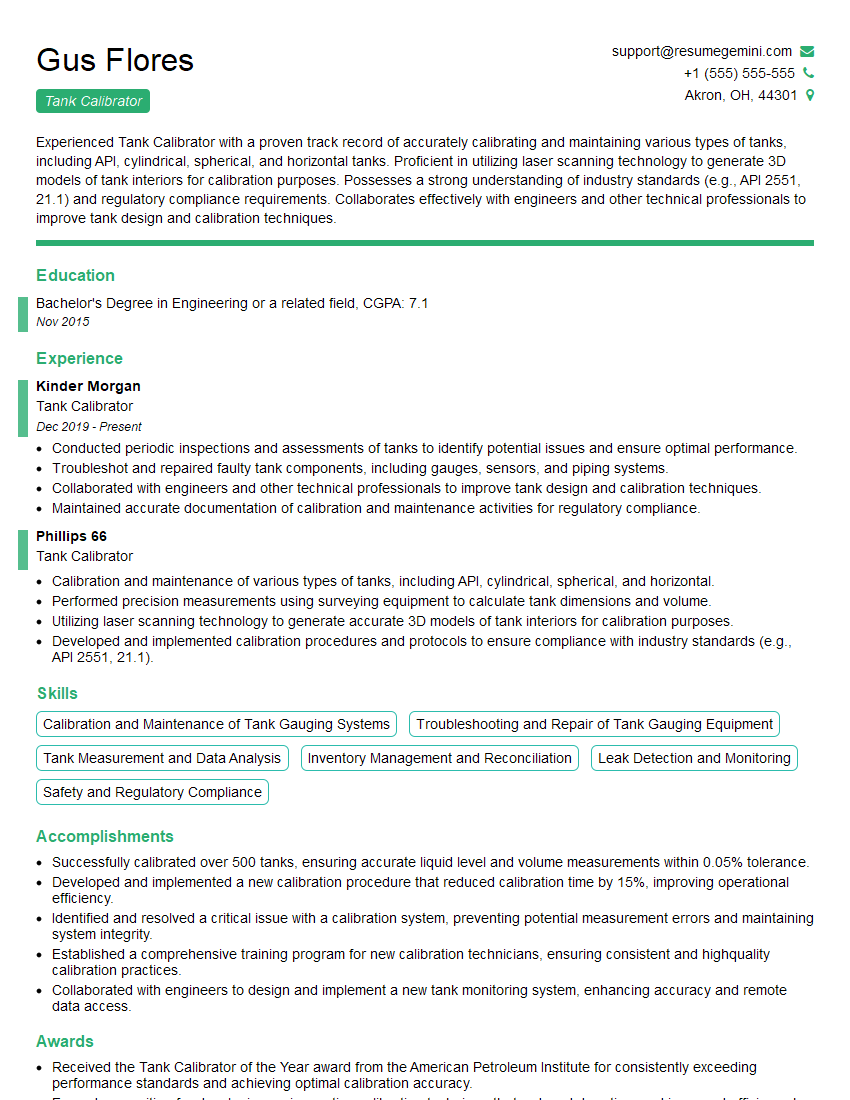

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tank Calibrator

1. What are the key responsibilities of a Tank Calibrator?

The primary responsibilities of a Tank Calibrator include:

- Calibrating and checking the accuracy of storage tanks, ensuring they meet industry standards and regulations.

- Using specialized equipment, such as laser levelers, tape measures, and plumb bobs.

- Calculating tank volumes and capacities.

- Preparing and maintaining calibration reports.

2. Describe the different methods used for tank calibration.

Manual Calibration

- Using a measuring tape or laser to measure the tank’s dimensions.

- Calculating the tank’s volume using mathematical formulas.

Hydrostatic Calibration

- Filling the tank with water and measuring the mass of the water.

- Calculating the tank’s volume based on the density of water.

Laser Calibration

- Using a laser scanner to create a 3D model of the tank’s interior.

- Calculating the tank’s volume based on the model.

3. What are the industry standards and regulations for tank calibration?

The industry standards and regulations for tank calibration vary depending on the jurisdiction. Some common standards include:

- API Standard 2555, “Tank Calibration and Measurement.”

- ASTM Standard D1220, “Standard Test Method for Calibrating Upright Cylindrical Tanks.”

- EPA Regulation 40 CFR Part 280, “Underground Storage Tanks.”

4. What is the importance of maintaining accurate tank calibration?

Maintaining accurate tank calibration is essential for:

- Ensuring the accuracy of inventory management.

- Preventing overfilling and underfilling of tanks.

- Complying with industry standards and regulations.

- Avoiding fines and penalties for inaccurate readings.

5. Describe the steps involved in calibrating a horizontal cylindrical tank.

- Measuring the tank’s length, diameter, and height.

- Calculating the tank’s volume using the formula V = π(d/2)²L.

- Marking the tank’s capacity at various levels.

- Verifying the calibration using a hydrostatic test.

6. What are the common errors that can occur during tank calibration?

Common errors that can occur during tank calibration include:

- Inaccurate measurements.

- Incorrect calculation of tank volume.

- Improper marking of tank capacity.

- Equipment malfunction.

- Human error.

7. What are the safety precautions that must be observed during tank calibration?

Safety precautions that must be observed during tank calibration include:

- Wearing appropriate safety gear, such as gloves, safety glasses, and coveralls.

- Using barricades and warning signs to prevent unauthorized access to the calibration area.

- Properly grounding all equipment.

- Following the manufacturer’s instructions for the calibration equipment.

- Being aware of potential hazards, such as spills, leaks, and fumes.

8. What are the different types of tank calibration equipment used in the industry?

- Laser levelers.

- Tape measures.

- Plumb bobs.

- Measuring tapes.

- Hydrostatic test kits.

9. How do you ensure the accuracy of your calibration measurements?

To ensure the accuracy of my calibration measurements, I take the following steps:

- Using calibrated and certified equipment.

- Following standardized calibration procedures.

- Taking multiple measurements and averaging the results.

- Verifying the calibration using a hydrostatic test.

10. What are your strengths and weaknesses as a Tank Calibrator?

My strengths as a Tank Calibrator include:

- Strong technical skills and knowledge of tank calibration methods.

- Attention to detail and accuracy.

- Experience in calibrating various types of tanks.

- Excellent communication and interpersonal skills.

My weaknesses include:

- I am still relatively new to the industry.

- I am not yet certified as a Tank Calibrator.

However, I am actively working on addressing these weaknesses by pursuing certification and gaining more experience in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tank Calibrator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tank Calibrator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tank Calibrator is responsible for the calibration, maintenance, and repair of tanks used in various industries, ensuring the accuracy and reliability of these vessels.

1. Calibration and Verification

Calibrate and verify tanks using advanced equipment and techniques, ensuring they meet industry standards and regulations.

- Conduct volume calibration on volumetric tanks using water or product displacement methods.

- Verify tank measurements and dimensions using laser scanners or other precision instruments.

2. Maintenance and Repair

Perform regular maintenance and repairs on tanks to ensure optimal performance and longevity.

- Inspect tanks for any damage, leaks, or wear and tear.

- Repair and replace damaged tank components, such as valves, seals, and gaskets.

3. Documentation and Reporting

Maintain accurate documentation and records related to tank calibration and maintenance activities.

- Prepare calibration reports detailing the calibration procedures, results, and any discrepancies.

- Report any maintenance or repair issues to management.

4. Safety and Compliance

Adhere to all safety protocols and industry regulations related to tank calibration and maintenance.

- Ensure compliance with OSHA and other safety standards.

- Use appropriate personal protective equipment (PPE) during calibration and maintenance activities.

Interview Tips

Preparing for an interview for a Tank Calibrator position requires thorough research and understanding of the job responsibilities and industry best practices. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Gather information about the company you’re applying for and the industry in which they operate. This will help you understand their specific requirements and challenges.

- Visit the company website to learn about their products, services, and company culture.

- Read industry publications and news articles to stay up-to-date on the latest trends and technologies.

2. Highlight Relevant Experience and Skills

Emphasize your experience in tank calibration and maintenance, even if it is in a different industry. Transferable skills, such as attention to detail, problem-solving, and safety awareness, are highly valued.

- Quantify your accomplishments using specific numbers and metrics whenever possible.

- Provide examples of how you have successfully calibrated and maintained tanks in a safe and efficient manner.

3. Demonstrate Industry Knowledge

Show that you are knowledgeable about the latest tank calibration techniques and industry regulations. This can be done by attending industry conferences, completing training programs, or obtaining certifications.

- Discuss your understanding of tank calibration methods, such as water displacement, laser scanning, and ultrasonic testing.

- Explain your knowledge of safety protocols and industry standards, such as OSHA and API.

4. Be Prepared for Technical Questions

Expect to be asked technical questions related to tank calibration and maintenance. Practice answering these questions clearly and concisely, using industry-specific terminology.

- Prepare for questions about calibration procedures, equipment, and safety protocols.

- Be ready to discuss your experience with troubleshooting and repairing tank issues.

5. Ask Thoughtful Questions

Asking insightful questions at the end of the interview shows that you are engaged and interested in the position. Prepare questions that demonstrate your curiosity and understanding of the company and industry.

- Ask about the specific responsibilities and challenges of the role.

- Inquire about the company’s commitment to safety and environmental compliance.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tank Calibrator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!