Are you gearing up for an interview for a Inserter Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Inserter Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

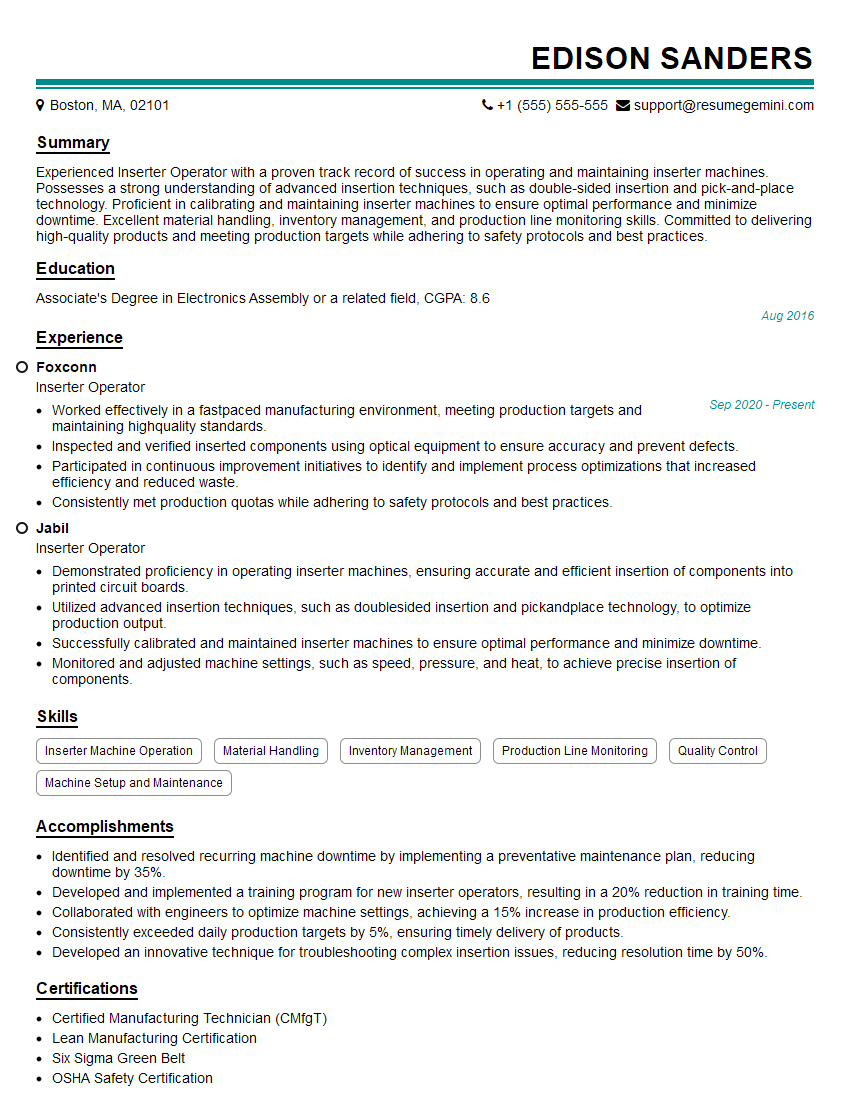

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Inserter Operator

1. Explain the basic principles of inserter machine operation?

The inserter machine operates on the principle of inserting components into a printed circuit board (PCB). The machine picks and places components onto the PCB, following a predetermined program. The basic steps involved in inserter machine operation are:

- Component loading: The components are loaded into the machine’s feeder system.

- Component pickup: The machine’s nozzle picks up a component from the feeder.

- Component placement: The machine places the component onto the PCB, at a specified location and orientation.

- Solder paste application: The machine applies solder paste to the component leads or pads.

- Component reflow soldering: The PCB is passed through a reflow oven, which melts the solder paste and permanently attaches the components to the PCB.

2. Describe the different types of components that can be inserted by an inserter machine?

Types of Components

- Axial components: These components have two leads that are parallel to each other. Examples include resistors, capacitors, and diodes.

- Radial components: These components have two leads that are perpendicular to each other. Examples include transistors, diodes, and capacitors.

- Surface mount components (SMCs): These components are small, leadless components that are mounted directly onto the PCB. Examples include resistors, capacitors, and transistors.

Shapes and Sizes

- Discrete components: These components are individual, standalone components.

- Arrays: These components are groups of components that are mounted together on a single substrate. Examples include resistor arrays and capacitor arrays.

- Odd-form components: These components have non-standard shapes or sizes. Examples include connectors and heat sinks.

3. What are the factors that affect the accuracy of an inserter machine?

- Machine calibration: The machine must be properly calibrated to ensure that it places components at the correct locations and orientations.

- Component tolerance: The accuracy of the machine is also affected by the tolerance of the components being inserted. Components that are not within tolerance may not be placed correctly.

- PCB design: The design of the PCB can also affect the accuracy of the machine. PCBs that are not properly designed may not allow the machine to place components correctly.

- Environmental factors: Environmental factors, such as temperature and humidity, can also affect the accuracy of the machine.

4. What are the different types of feeders used in inserter machines?

- Tape feeders: Tape feeders use a continuous strip of tape to hold and feed components.

- Tube feeders: Tube feeders use a tube to hold and feed components.

- Stick feeders: Stick feeders use a stick to hold and feed components.

- Bulk feeders: Bulk feeders use a large bin or hopper to hold and feed components.

- Tray feeders: Tray feeders use a tray to hold and feed components.

5. What are the different types of nozzles used in inserter machines?

- Standard nozzles: Standard nozzles are used to insert axial and radial components.

- Vacuum nozzles: Vacuum nozzles are used to insert SMCs.

- Odd-form nozzles: Odd-form nozzles are used to insert components with non-standard shapes or sizes.

6. What are the safety precautions that should be taken when operating an inserter machine?

- Wear appropriate safety gear: Wear safety glasses, gloves, and a lab coat when operating the machine.

- Keep the work area clean: Clean the work area regularly to prevent the buildup of dust and debris.

- Do not operate the machine if it is not properly calibrated: The machine must be properly calibrated to ensure that it places components at the correct locations and orientations.

- Do not insert components that are not within tolerance: Components that are not within tolerance may not be placed correctly.

- Do not operate the machine in an unsafe environment: The machine should not be operated in an environment that is wet, dusty, or has excessive vibration.

7. What are the maintenance procedures that should be performed on an inserter machine?

- Regular cleaning: The machine should be cleaned regularly to prevent the buildup of dust and debris.

- Calibration: The machine should be calibrated regularly to ensure that it places components at the correct locations and orientations.

- Feeder maintenance: The feeders should be inspected and maintained regularly to ensure that they are functioning properly.

- Nozzle maintenance: The nozzles should be inspected and replaced regularly to ensure that they are in good condition.

- Software updates: The machine software should be updated regularly to ensure that it is up-to-date with the latest features and bug fixes.

8. What are the troubleshooting procedures that should be performed when an inserter machine is not functioning properly?

- Check the power supply: Ensure that the machine is plugged in and that the power switch is turned on.

- Check the air supply: Ensure that the machine has a sufficient air supply.

- Check the feeders: Ensure that the feeders are filled with components and that they are functioning properly.

- Check the nozzles: Ensure that the nozzles are in good condition and that they are properly aligned.

- Check the software: Ensure that the machine software is up-to-date and that there are no error messages.

9. What are the quality control procedures that should be followed to ensure that components are inserted correctly?

- Visual inspection: The components should be visually inspected to ensure that they are placed at the correct locations and orientations.

- Automated optical inspection (AOI): AOI is a machine vision system that can automatically inspect components to ensure that they are placed correctly.

- X-ray inspection: X-ray inspection can be used to inspect components to ensure that they are properly soldered.

10. What are the different types of inserter machines?

- Axial inserter machines: Axial inserter machines are used to insert axial components.

- Radial inserter machines: Radial inserter machines are used to insert radial components.

- Surface mount inserter machines (SMIMs): SMIMs are used to insert SMCs.

- Multi-function inserter machines: Multi-function inserter machines can insert a variety of component types, including axial, radial, and SMCs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Inserter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Inserter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Inserter Operators play a crucial role in the production process, ensuring the smooth and efficient operation of inserter machines.

1. Machine Operation

Operate inserter machines to insert components into printed circuit boards (PCBs) or other electronic assemblies.

- Set up and adjust inserter machines according to production specifications.

- Load and unload PCBs or components into and out of the inserter machines.

- Monitor machine operation and make necessary adjustments or repairs to ensure optimal performance.

2. Quality Control

Inspect PCBs and components before and after insertion to ensure accuracy and quality.

- Check for correct component placement, orientation, and soldering.

- Identify and resolve any defects or errors promptly.

3. Production Monitoring

Track production output and identify areas for improvement.

- Monitor machine performance and production rates.

- Record and analyze data to identify bottlenecks and optimize processes.

4. Maintenance and Troubleshooting

Perform routine maintenance and troubleshoot minor issues with inserter machines.

- Clean and lubricate machines.

- Replace worn or damaged parts.

- Resolve minor mechanical or electrical issues.

Interview Tips

Preparing thoroughly for an Inserter Operator interview is essential to showcase your skills and increase your chances of success.

1. Research the Company and Industry

Gather information about the company’s products, services, and industry trends. This knowledge will demonstrate your interest and enthusiasm for the role.

- Visit the company’s website and LinkedIn page.

- Read industry news and articles.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating inserter machines, including any certifications or experience with specific models or software.

- Describe your process for setting up and calibrating inserter machines.

- Explain your experience in troubleshooting and resolving machine issues.

3. Showcase Your Quality Control Mindset

Demonstrate your understanding of quality control principles and your commitment to delivering high-quality products.

- Explain your methods for inspecting PCBs and components before and after insertion.

- Describe your experience in identifying and correcting defects.

4. Emphasize Your Problem-Solving Skills

Highlight your ability to analyze issues, identify solutions, and make informed decisions under pressure.

- Provide examples of situations where you resolved production problems.

- Explain how you approach and prioritize tasks.

5. Prepare for Common Interview Questions

Anticipate and prepare for common interview questions related to your experience, skills, and career goals.

- Example Outline:

- “Can you describe your experience operating inserter machines?”

- “What are your strengths and weaknesses as an Inserter Operator?”

- “Where do you see yourself in the next 5 years?”

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Inserter Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Inserter Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.