Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Microfilm Mounter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

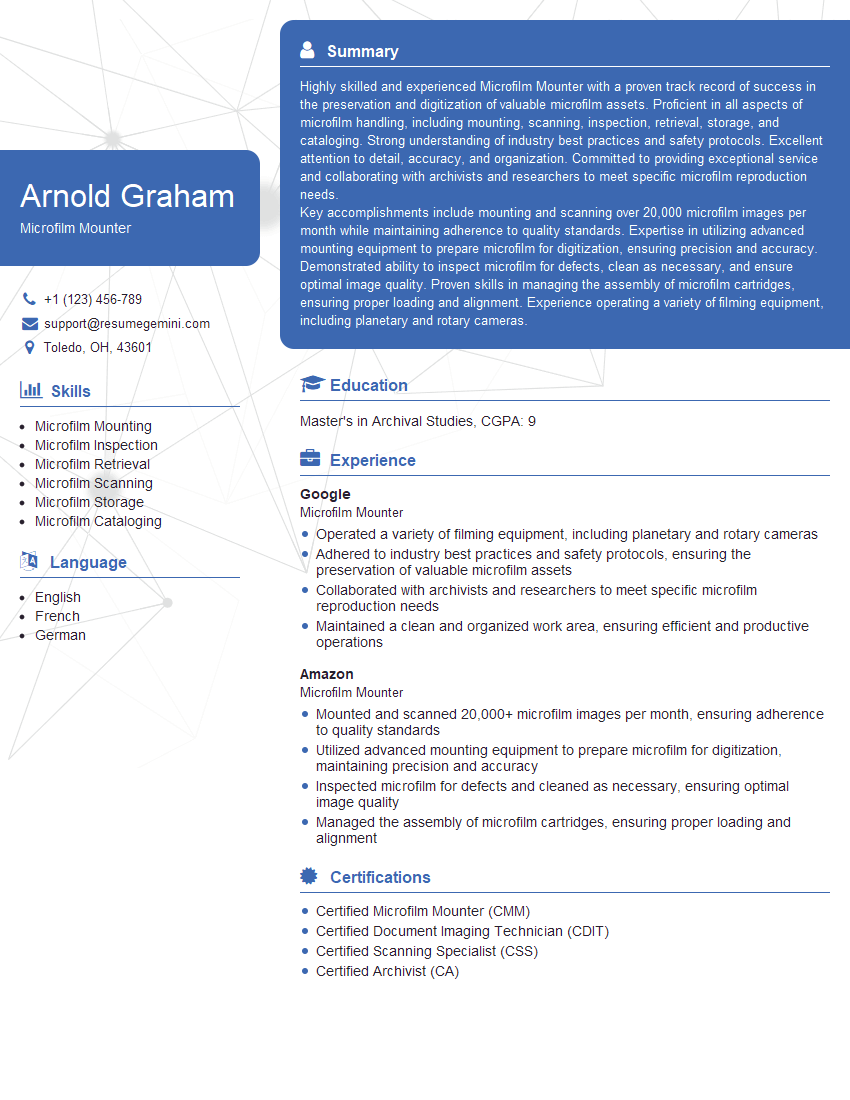

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Microfilm Mounter

1. What is the function of a vacuum flattening table?

A vacuum flattening table is used to flatten and smooth microfilm before mounting it. The table has a vacuum chamber that suctions the microfilm down, which helps to remove wrinkles and creases. The table also has a heated surface that helps to soften the microfilm and make it more pliable.

2. What are the different types of mounting machines?

Dry mounting machines

- Dry mounting machines use heat and pressure to adhere microfilm to a mounting board.

- These machines are typically used for mounting larger pieces of microfilm, such as rolls or sheets.

Wet mounting machines

- Wet mounting machines use a liquid adhesive to adhere microfilm to a mounting board.

- These machines are typically used for mounting smaller pieces of microfilm, such as microfiche or aperture cards.

3. What are the different types of mounting boards?

- Acid-free mounting boards are made from materials that will not damage microfilm over time.

- Lignin-free mounting boards are made from materials that do not contain lignin, which is a chemical that can cause microfilm to yellow and deteriorate.

- Buffered mounting boards are made from materials that have been treated with a buffer to neutralize acids and prevent microfilm from damage.

4. What is the purpose of a mounting press?

A mounting press is used to apply pressure to microfilm that is being mounted to a mounting board. The pressure helps to adhere the microfilm to the board and prevents it from curling or buckling.

5. What are the different types of microfilm cutting tools?

There are three main types of microfilm cutting tools:

- Rotary cutters are used to cut microfilm in a straight line.

- Guillotine cutters are used to cut microfilm in a straight line or at an angle.

- Microfilm scissors are used to cut microfilm in a variety of shapes and sizes.

6. What are the different types of microfilm splicing tapes?

- Polyester splicing tape is a strong and durable tape that is used to splice microfilm together.

- Paper splicing tape is a less durable tape that is used to splice microfilm together temporarily.

- Mylar splicing tape is a clear tape that is used to splice microfilm together and is invisible when applied.

7. What are the different types of microfilm storage containers?

- Acid-free storage containers are made from materials that will not damage microfilm over time.

- Lignin-free storage containers are made from materials that do not contain lignin, which is a chemical that can cause microfilm to yellow and deteriorate.

- Buffered storage containers are made from materials that have been treated with a buffer to neutralize acids and prevent microfilm from damage.

8. What are the different types of microfilm retrieval systems?

- Manual retrieval systems are used to retrieve microfilm from a storage container by hand.

- Semi-automatic retrieval systems use a machine to retrieve microfilm from a storage container.

- Automatic retrieval systems use a computer to retrieve microfilm from a storage container.

9. What are the different types of microfilm duplicating machines?

- Contact duplicators make a direct copy of microfilm by exposing a new piece of film to the light from the original film.

- Optical duplicators make a copy of microfilm by using a lens to focus the light from the original film onto a new piece of film.

- Digital duplicators make a copy of microfilm by scanning the original film and then creating a digital file that can be used to produce a new piece of film.

10. What are the different types of microfilm scanning equipment?

- Flatbed scanners are used to scan microfilm that is mounted on a flat surface.

- Roll scanners are used to scan microfilm that is rolled up into a roll.

- Continuous-feed scanners are used to scan microfilm that is fed through the scanner continuously.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Microfilm Mounter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Microfilm Mounter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Microfilm Mounters are responsible for creating and maintaining microfilm records. These records are used in a variety of industries, from healthcare to finance, and it is essential that they are accurate and complete. Microfilm Mounters work in a variety of settings, including offices, libraries, and archives.

1. Mounting Microfilm

The primary responsibility of a Microfilm Mounter is to mount microfilm images onto aperture cards or other media. This involves carefully aligning the images and securing them in place using a specialized mounting machine. Microfilm Mounters must be able to work with a variety of microfilm formats, including 16mm, 35mm, and 70mm. They must also be able to handle delicate materials and work in a clean and dust-free environment.

2. Indexing Microfilm

In addition to mounting microfilm, Microfilm Mounters are also responsible for indexing the images. This involves creating a system for organizing and retrieving the images, so that they can be easily located and accessed. Microfilm Mounters may use a variety of indexing systems, including numerical, alphabetical, and keyword-based systems.

3. Maintaining Microfilm Records

Microfilm Mounters are also responsible for maintaining microfilm records. This involves storing the records in a climate-controlled environment and ensuring that they are protected from damage. Microfilm Mounters may also be responsible for repairing or replacing damaged records.

4. Quality Control

Microfilm Mounters must adhere to strict quality control standards. This involves inspecting the mounted microfilm for defects, such as misalignment, scratches, or tears. Microfilm Mounters must also ensure that the indexed images are accurate and complete.

Interview Tips

Preparing for an interview for a Microfilm Mounter position can be a daunting task. However, by following a few simple tips, you can increase your chances of success.

1. Research the Company

Before your interview, take the time to research the company you are applying to. This will give you a good understanding of their business, their values, and their culture. You can also use this information to tailor your answers to the interviewer’s questions.

2. Practice Your Answers

Once you have researched the company, take the time to practice your answers to common interview questions. This will help you to feel more confident and prepared during the interview.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or dress pants and a button-down shirt or blouse. You should also make sure your shoes are clean and polished.

4. Be on Time

Punctuality is important, so make sure you arrive for your interview on time. If you are running late, be sure to call or email the interviewer to let them know.

5. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Microfilm Mounter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!