Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Head Sawyer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

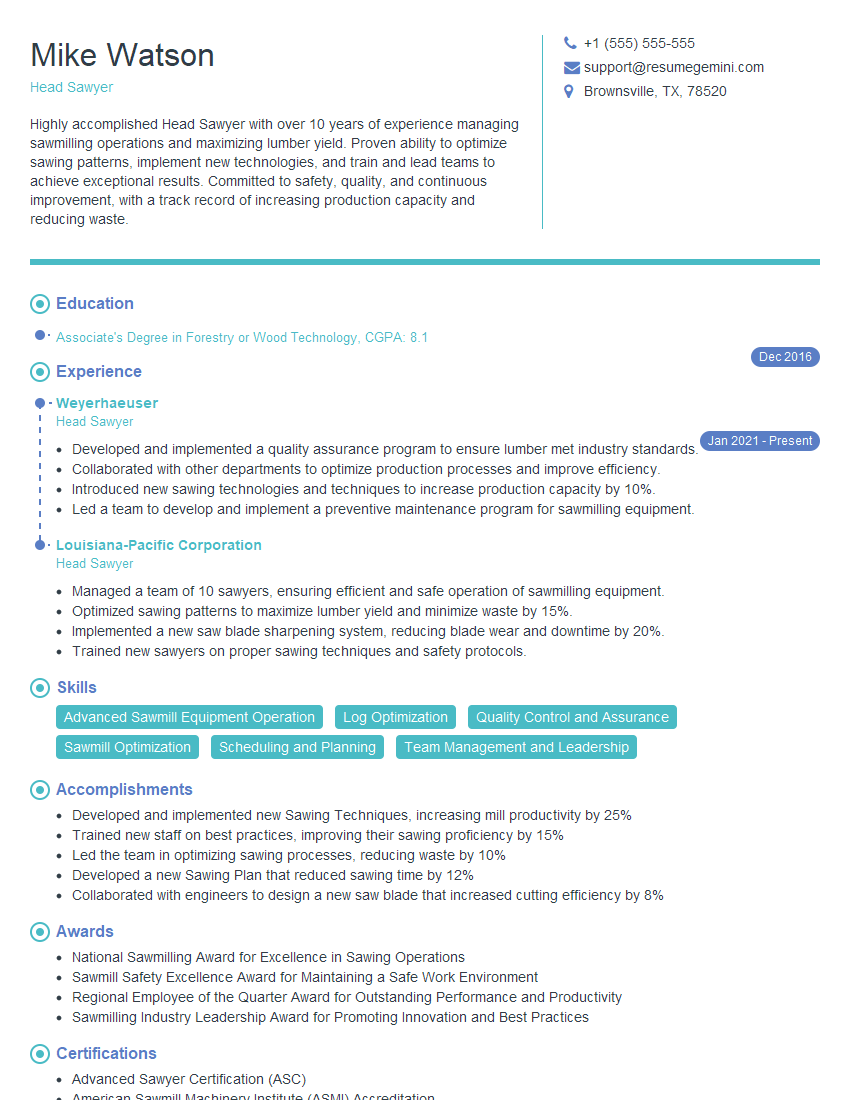

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Head Sawyer

1. Describe the key responsibilities and challenges of a Head Sawyer in a sawmill operation?

As the Head Sawyer in a sawmill operation, my key responsibilities include:

- Operating and maintaining sawmill machinery, including headrigs and resaws

- Setting up and adjusting sawblades to achieve desired lumber dimensions and quality

- Monitoring and controlling the flow of logs and lumber through the sawmill

- Ensuring the safety and efficiency of the sawing operation

- Training and supervising sawyers and other sawmill personnel

One of the primary challenges in this role is optimizing lumber yield while maintaining quality standards. This requires a deep understanding of wood properties, saw blade selection, and machine settings.

2. What factors influence the quality of sawn lumber?

Saw Blade Selection and Maintenance

- Selecting the appropriate saw blade type, tooth geometry, and sharpness for the desired lumber quality

- Ensuring proper saw blade tension and alignment to prevent vibration and saw blade deflection

Machine Settings

- Setting and maintaining optimal headrig and resaw feed rates, carriage speeds, and saw blade RPM to achieve desired lumber dimensions and surface finish

- Adjusting machine settings to minimize waste and maximize lumber recovery

Log Characteristics

- Assessing log diameter, shape, grain orientation, and defects to determine optimal sawing patterns

- Adjusting machine settings and saw blade selection based on log characteristics to achieve desired lumber quality

3. How do you ensure the safety of the sawing operation?

Ensuring the safety of the sawing operation is paramount. I prioritize the following measures:

- Regularly inspecting and maintaining sawmill machinery to identify and устранение potential hazards

- Implementing and enforcing safety protocols, including proper use of personal protective equipment (PPE)

- Providing comprehensive training to sawyers and other sawmill personnel on safe work practices

- Regularly monitoring and assessing the sawing environment to identify and mitigate any potential risks

- Maintaining a clean and organized work area to prevent tripping and other accidents

4. How do you stay up-to-date on the latest advancements in sawmilling technology?

To stay current with industry advancements, I actively engage in the following:

- Attending industry conferences, workshops, and trade shows

- Reading industry publications and technical journals

- Networking with other sawmill professionals and experts

- Seeking opportunities for professional development and training

- Collaborating with equipment manufacturers and suppliers to evaluate and implement new technologies

5. How do you handle situations where the desired lumber quality is not being achieved?

When the desired lumber quality is not being achieved, I follow a systematic approach:

- Assess the lumber quality issues and identify potential causes

- Inspect the sawing machinery, saw blades, and machine settings to identify any deviations from optimal parameters

- Analyze log characteristics and adjust sawing patterns or machine settings accordingly

- Consult with other sawmill personnel, including sawyers and maintenance technicians, to gather different perspectives and insights

- Implement corrective actions and monitor the results to ensure the desired lumber quality is achieved

6. How do you optimize lumber yield while maintaining quality standards?

Optimizing lumber yield while maintaining quality standards requires a balanced approach:

- Selecting the most appropriate sawing patterns based on log characteristics to minimize waste

- Fine-tuning machine settings, such as feed rates and saw blade RPM, to maximize lumber recovery

- Ensuring proper saw blade maintenance to prevent excessive kerf loss

- Implementing quality control measures to identify and remove defective lumber

- Monitoring lumber yield and quality data to identify areas for improvement

7. How do you effectively train and supervise sawyers and other sawmill personnel?

Effective training and supervision are crucial for maintaining a skilled and efficient sawmill workforce:

- Develop comprehensive training programs that cover all aspects of sawing operations, including safety protocols

- Provide hands-on training and supervision to ensure proper sawyer techniques and machine operation

- Regularly assess sawyer performance and provide feedback to identify areas for improvement

- Create a positive and supportive work environment that encourages teamwork and continuous learning

- Empower sawyers and other sawmill personnel to take ownership of their responsibilities and contribute to overall sawmill efficiency.

8. How do you manage and resolve conflicts that may arise within the sawmill team?

Conflict resolution is an essential aspect of maintaining a harmonious and productive work environment:

- Establish clear communication channels and encourage open dialogue to address concerns or disagreements promptly

- Actively listen to all perspectives involved in the conflict to gain a comprehensive understanding of the situation

- Identify common ground and areas of agreement to facilitate compromise and resolution

- Develop and implement fair and equitable solutions that address the concerns of all parties involved

- Monitor the situation and provide support to ensure that conflicts are resolved effectively and do not recur

9. How do you measure and evaluate the performance of the sawing operation?

Performance evaluation is crucial for continuous improvement:

- Establish key performance indicators (KPIs) such as lumber yield, quality, and production efficiency

- Regularly collect and analyze data related to these KPIs to identify areas of strength and weakness

- Compare performance against industry benchmarks and best practices to identify opportunities for improvement

- Provide feedback to sawyers and other sawmill personnel based on performance evaluation results

- Use performance evaluation as a basis for training, development, and resource allocation decisions

10. How do you stay motivated and maintain a positive attitude in a demanding work environment?

Maintaining motivation and a positive attitude is essential in a demanding work environment:

- Set clear and achievable goals to provide a sense of purpose and direction

- Continuously seek opportunities for professional growth and development to enhance skills and knowledge

- Foster a positive and supportive work environment that promotes collaboration and teamwork

- Recognize and appreciate the contributions of sawyers and other sawmill personnel to boost morale

- Maintain a work-life balance to prevent burnout and maintain overall well-being

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Head Sawyer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Head Sawyer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Head Sawyer is responsible for overseeing the operations of a saw mill, ensuring efficient and safe production of lumber. The key job responsibilities include:

1. Production Management

Managing the production schedule, ensuring timely completion of orders

- Monitoring production processes and making adjustments to optimize efficiency

- Maintaining inventory of raw materials and finished goods

2. Equipment Maintenance

Ensuring proper maintenance and upkeep of all sawing equipment

- Identifying and resolving equipment malfunctions promptly

- Coordinating with maintenance personnel to ensure smooth operations

3. Quality Control

Monitoring the quality of lumber produced, ensuring it meets specifications

- Conducting regular inspections and implementing quality control measures

- Addressing any quality issues promptly

4. Safety Management

Prioritizing the safety of employees and implementing safety protocols

- Conducting safety training and ensuring compliance with regulations

- Inspecting work areas and equipment regularly

Interview Tips

To ace the interview for a Head Sawyer position, it is crucial to:

1. Research the Company and Industry

Demonstrate your understanding of the company’s operations and the saw mill industry.

- Visit the company website and review their mission, values, and products.

- Read industry publications and attend trade shows to stay updated on trends and technologies.

2. Highlight Relevant Experience

Emphasize your experience in production management, equipment maintenance, and quality control within the saw mill industry.

- Quantify your accomplishments using specific metrics, such as percentage increases in production efficiency or reduction in equipment downtime.

- Provide examples of how you have implemented successful safety programs or resolved quality issues.

3. Showcase Leadership Abilities

Demonstrate your ability to lead and motivate a team, as well as make sound decisions.

- Share examples of how you have successfully managed a team and achieved production goals.

- Describe how you have handled challenging situations and made critical decisions.

4. Prepare for Technical Questions

Expect questions related to sawing equipment, production processes, and quality standards.

- Review common sawing methods, such as circular sawing, band sawing, and gang sawing.

- Understand the principles of lumber grading and quality control.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Head Sawyer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.