Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Turpentine Farmer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

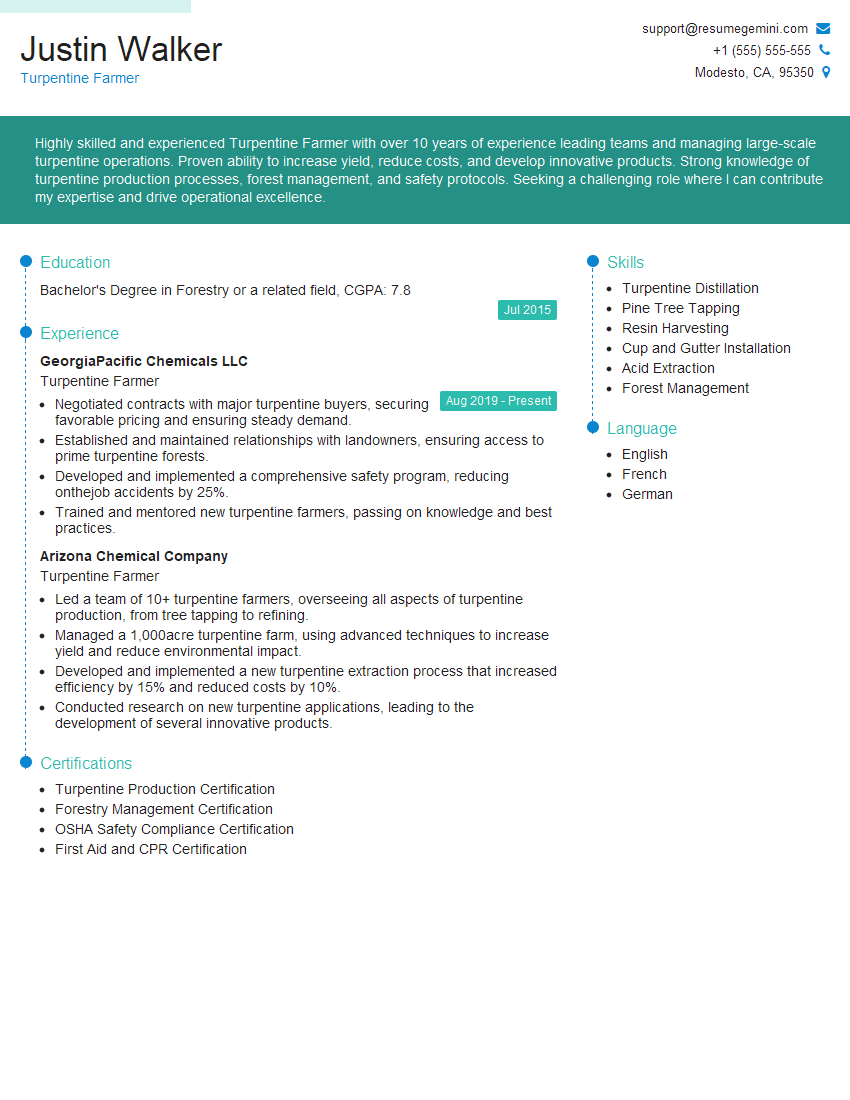

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Turpentine Farmer

1. Describe the process of tapping pine trees for turpentine.

The turpentine tapping process typically involves the following steps:

- Making a “face” on the tree: A rectangular section of bark is removed from the trunk of the tree, typically around knee height.

- Installing a gutter: A metal or plastic gutter is attached to the face to collect the flowing turpentine.

- Creating streaks: Diagonal cuts are made into the face of the tree to encourage the flow of turpentine.

- Collecting the turpentine: The turpentine flows down the streaks into the gutter, where it is periodically collected.

2. How do you determine the optimal time to tap pine trees for turpentine?

Factors to Consider:

- Tree age and size: Younger and larger trees typically yield more turpentine.

- Season: Spring and early summer months are generally considered the best time for tapping.

- Climate: Warm and humid conditions promote turpentine flow.

- Tree health: Healthy trees with good resin production are ideal for tapping.

Additional Considerations:

- Foresters or experienced turpentine farmers may use tree growth rings and specific tapping seasons to optimize yields.

- The amount of time between tapping cycles also affects turpentine production.

3. What is the importance of controlling wildfires in turpentine farming operations?

Wildfires pose significant risks to turpentine farming operations:

- Destruction of trees: Fires can quickly spread and destroy pine forests, reducing the supply of trees for turpentine production.

- Loss of equipment: Wildfires can damage or destroy tapping equipment, such as gutters and collection tanks.

- Air pollution: Burning turpentine can release harmful pollutants into the atmosphere, impacting the environment and human health.

- Safety hazards: Wildfires can create dangerous conditions for firefighters and turpentine farmers working in the area.

4. How do you ensure the sustainability of turpentine farming operations?

Ensuring the sustainability of turpentine farming involves adopting practices that:

- Protect tree health: Using sustainable tapping techniques that minimize damage to trees.

- Conserve water resources: Implementing efficient water management practices during turpentine processing.

- Reduce waste: Recycling or repurposing materials used in turpentine production.

- Protect biodiversity: Maintaining healthy ecosystems around turpentine farming areas.

- Comply with regulations: Adhering to environmental and safety regulations governing turpentine farming.

5. Describe the different grades of turpentine and their uses.

Turpentine is classified into grades based on its purity and quality:

Gum turpentine

- Highest grade, derived from the distillation of turpentine collected directly from trees.

- Used in paints, varnishes, and other products requiring a solvent with high purity.

Steam-distilled turpentine

- Produced by steam distillation of pine wood chips or stumps.

- Used in industrial applications, cleaning products, and as a solvent.

Sulfate turpentine

- Byproduct of the paper-making process.

- Used as a solvent, diluent, and in the production of other chemicals.

6. How do you maintain and calibrate the equipment used in turpentine farming?

Properly maintaining and calibrating equipment is crucial in turpentine farming:

- Tapping tools: Regularly sharpen tapping tools to ensure efficient and accurate cuts.

- Gutters: Inspect gutters for damage and leaks, replace or repair as needed.

- Collection tanks: Calibrate collection tanks to accurately measure the volume of turpentine collected.

- Processing equipment: Follow manufacturer’s instructions for regular maintenance and calibration of distillation or extraction equipment.

7. What are the safety protocols for working in a turpentine farming environment?

Turpentine farming involves potential hazards:

- Flammable materials: Turpentine is highly flammable, so proper precautions are essential to prevent fires.

- Toxic vapors: Turpentine vapors can be harmful if inhaled, so adequate ventilation and respiratory protection are required.

- Sharp tools: Tapping tools can cause injuries if not handled carefully.

- Working in remote areas: Turpentine farming often takes place in isolated areas, so proper communication and emergency response plans are important.

8. Can you describe the market trends and demand for turpentine?

The market for turpentine is influenced by several factors:

Growing consumption:

- Increasing demand in developing countries for paints and solvents.

- Growth in the chemical industry for the production of synthetic flavors and fragrances.

Environmental concerns:

- Government regulations limiting the use of synthetic solvents in certain applications.

- Growing consumer preference for eco-friendly products.

Alternative sources:

- Rising production of turpentine substitutes, such as petroleum-based solvents.

- Development of biodegradable or sustainable alternatives.

9. What are the key challenges faced in the turpentine farming industry?

Turpentine farming faces several challenges:

- Declining tree populations: Diseases, pests, and deforestation can reduce the availability of pine trees for tapping.

- Competition from synthetic substitutes: Petroleum-based solvents are often cheaper and more readily available than turpentine.

- Climate change: Changing weather patterns can affect the yield and quality of turpentine.

- Environmental regulations: Restrictions on the use of turpentine can impact the industry’s profitability.

10. How do you stay updated on the latest advancements and best practices in turpentine farming?

Keeping up with industry trends and innovations is important:

- Attend industry conferences and workshops: Network with other turpentine farmers and learn about new techniques.

- Read industry publications and online resources: Stay informed about research and developments in tapping methods, equipment, and market trends.

- Consult with experts and extension services: Seek guidance from specialists who can provide valuable advice and support.

- Participate in industry organizations: Engage with organizations dedicated to promoting and supporting the turpentine farming sector.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Turpentine Farmer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Turpentine Farmer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Turpentine Farmers are responsible for the production and harvesting of turpentine, a natural solvent derived from pine trees. Their duties involve various aspects of the turpentine production process.

1. Pine Tree Cultivation

Turpentine Farmers play a crucial role in pine tree cultivation to ensure a steady supply of raw materials. They:

- Select, plant, and nurture pine trees suitable for turpentine production.

- Manage the growth and health of pine trees through fertilization, pruning, and pest control.

2. Turpentine Extraction

Turpentine extraction is the core responsibility of Turpentine Farmers. They:

- Use specialized equipment to tap pine trees, creating channels to collect resin.

- Monitor the flow of resin and adjust tapping techniques to optimize yield.

- Collect the resin from the tapping channels and process it to extract turpentine.

3. Turpentine Production

Turpentine production involves various processes to convert raw resin into usable turpentine. Turpentine Farmers:

- Operate distillation or solvent extraction equipment to separate turpentine from other components.

- Monitor and control the production process to ensure quality and yield.

- Package and store turpentine for transportation and distribution.

4. Safety and Environmental Compliance

Turpentine production involves potential hazards. Turpentine Farmers must:

- Maintain a safe working environment by following established safety protocols.

- Comply with environmental regulations and industry best practices to minimize the impact on the ecosystem.

Interview Tips

Thorough preparation can significantly enhance your chances of success in a Turpentine Farmer interview. Consider the following tips:

1. Research the Industry

Familiarize yourself with the turpentine production industry, including market trends, key players, and sustainable practices.

- Read industry publications, attend webinars, and connect with professionals in the field.

- Understand the different methods of turpentine extraction and production.

2. Highlight Relevant Skills

Showcase your skills and experience that align with the key responsibilities of a Turpentine Farmer. Emphasize your:

- Knowledge of pine tree cultivation and management

- Expertise in turpentine extraction and production techniques

- Ability to operate and maintain specialized equipment

- Commitment to safety and environmental compliance

3. Prepare for Industry-Specific Questions

Anticipate questions about your understanding of the industry and your ability to handle specific tasks. For example:

- Describe your experience in pine tree cultivation and how you ensure optimal resin yield.

- Explain the process of turpentine extraction and how you optimize quality and efficiency.

- Discuss the safety measures you implement to minimize risks in the workplace.

4. Practice Your Responses

Rehearse your answers to common interview questions, such as those related to your skills, experience, and motivation. Practice in front of a mirror or with a friend to improve your delivery and confidence.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Quantify your accomplishments whenever possible to demonstrate your impact.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Turpentine Farmer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!