Are you gearing up for a career in Tobacco Classer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tobacco Classer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

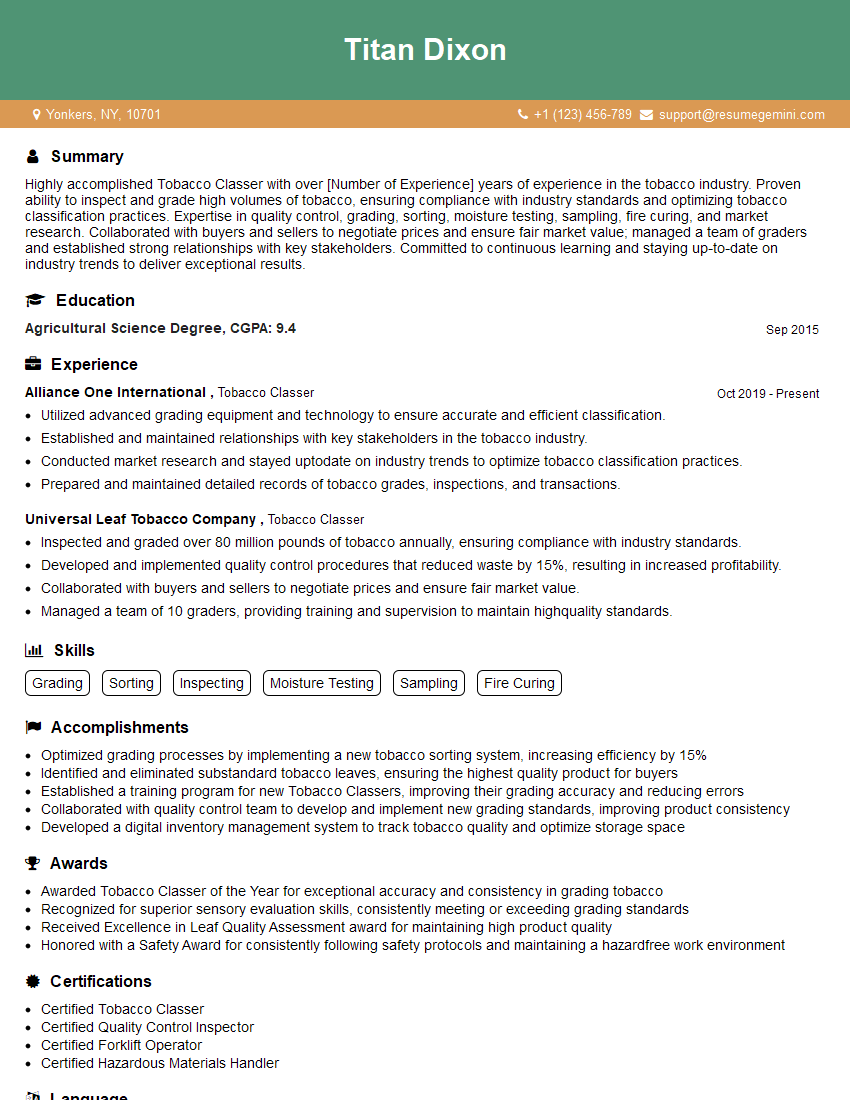

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tobacco Classer

1. Describe the process of tobacco classing?

- Identify the different grades of tobacco.

- Sort the tobacco into the appropriate grades.

- Grade the tobacco based on various quality factors, such as color, texture, and aroma.

- Inspect and identify any defects or impurities in the tobacco.

- Package and store the tobacco according to the grade and quality.

2. What are the key factors to consider when classifying tobacco?

Color and texture

- The color of the tobacco leaf can indicate its maturity and quality. Lighter-colored leaves are typically younger and more delicate, while darker leaves are older and more mature.

- The texture of the tobacco leaf can also indicate its quality. Smooth, even-textured leaves are typically of higher quality than rough, bumpy leaves.

Aroma and flavor

- The aroma of the tobacco leaf is an important factor to consider when classifying tobacco. Pleasant aromas, such as floral or fruity scents, are indicative of higher quality tobacco.

- The flavor of the tobacco leaf is also important to consider. Sweet, mild flavors are typically preferred over harsh, bitter flavors.

Defects and impurities

- Defects, such as holes, tears, or discoloration, can lower the quality of the tobacco leaf.

- Impurities, such as dirt, sand, or insects, can also lower the quality of the tobacco leaf.

3. What are the different grades of tobacco?

- Grade A: This is the highest grade of tobacco and is typically used in premium cigars and pipe tobaccos.

- Grade B: This is a medium-grade tobacco and is typically used in mid-priced cigars and pipe tobaccos.

- Grade C: This is a low-grade tobacco and is typically used in budget-friendly cigars and pipe tobaccos.

4. Describe the role of a tobacco classer in a tobacco processing facility.

- Classify tobacco leaves into different grades based on quality factors such as color, texture, aroma, and flavor.

- Inspect tobacco leaves for defects and impurities.

- Package and store tobacco leaves according to grade and quality.

- Maintain records of tobacco classification and quality.

- Assist in the development and implementation of tobacco quality control programs.

5. Explain the importance of accurate tobacco classing.

- Accurate tobacco classing ensures that tobacco products are of consistent quality.

- It helps to maintain the reputation of tobacco brands and products.

- It helps to maximize the value of tobacco crops.

6. Describe any recent advancements in tobacco classing technology.

- Optical sorting: This technology uses cameras and sensors to automatically sort tobacco leaves based on their color, texture, and other quality factors.

- Electronic noses: These devices can be used to identify and quantify the aroma and flavor compounds in tobacco leaves.

- Near-infrared spectroscopy: This technology can be used to measure the chemical composition of tobacco leaves and predict their quality.

7. Describe your experience in training and supervising other tobacco classers.

- I have over 10 years of experience in training and supervising other tobacco classers.

- I have developed and implemented training programs for new and experienced classers.

- I have provided ongoing coaching and support to classers to help them improve their skills and knowledge.

- I have a proven track record of success in developing and maintaining a team of highly skilled and motivated classers.

8. Describe your experience in developing and implementing tobacco quality control programs.

- I have over 15 years of experience in developing and implementing tobacco quality control programs.

- I have worked with growers, processors, and manufacturers to establish and maintain quality standards for tobacco products.

- I have developed and implemented testing methods to assess the quality of tobacco leaves and products.

- I have a proven track record of success in improving the quality of tobacco products.

9. Describe your experience in using tobacco classing equipment and software.

- I have over 10 years of experience in using tobacco classing equipment and software.

- I am proficient in using optical sorting machines, electronic noses, and near-infrared spectroscopy equipment.

- I am also proficient in using tobacco classing software to manage and analyze data.

10. Describe your experience in working with tobacco growers and processors.

- I have over 15 years of experience in working with tobacco growers and processors.

- I have provided guidance to growers on how to improve the quality of their tobacco crops.

- I have worked with processors to develop and implement quality control programs.

- I have a strong understanding of the challenges and opportunities facing the tobacco industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tobacco Classer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tobacco Classer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tobacco Classers are responsible for classifying and grading tobacco leaves based on their quality, color, texture, and other characteristics. Their primary duties include:

1. Tobacco Leaf Evaluation

Inspecting tobacco leaves to determine their grade and quality.

- Analyzing leaf size, shape, color, and texture.

- Identifying and assessing defects or blemishes.

2. Tobacco Leaf Sorting

Sorting and classifying tobacco leaves into different grades based on established standards.

- Using a hand-held grading device or automated machinery to classify leaves.

- Separating leaves into categories such as wrapper, binder, and filler.

3. Tobacco Leaf Packing

Packing and preparing tobacco leaves for storage or shipment.

- Bundling and grading leaves into bales or bundles.

- Labeling and documenting the contents of each bale.

4. Quality Control

Maintaining the quality of tobacco products by ensuring proper handling and storage.

- Monitoring temperature and humidity levels in storage facilities.

- Inspecting tobacco leaves for signs of damage or contamination.

Interview Tips

Preparing for an interview for a Tobacco Classer position requires thorough research and practice. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, values, and tobacco-related operations. Understanding the industry’s current trends and challenges will demonstrate your interest and knowledge.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Highlight Your Tobacco Expertise

Showcase your knowledge of tobacco leaf grading, classification, and quality assessment techniques. Quantify your experience and provide specific examples of your accomplishments.

- Describe your experience with different tobacco varieties and their characteristics.

- Discuss any certifications or training programs you have completed.

3. Emphasize Quality Control and Attention to Detail

Tobacco Classers are responsible for ensuring the quality of tobacco products. Highlight your ability to identify defects, maintain proper storage conditions, and follow established quality standards.

- Describe your experience with implementing and maintaining quality control procedures.

- Provide examples of how you have identified and resolved quality issues.

4. Prepare Industry-Specific Questions

Asking thoughtful questions related to the tobacco industry and the company’s operations shows your interest and engagement. Prepare questions about the company’s grading standards, sustainability practices, or market trends.

- Inquire about the company’s quality assurance processes.

- Ask how they stay up-to-date with industry regulations.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tobacco Classer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.