Feeling lost in a sea of interview questions? Landed that dream interview for Casing Grader but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Casing Grader interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

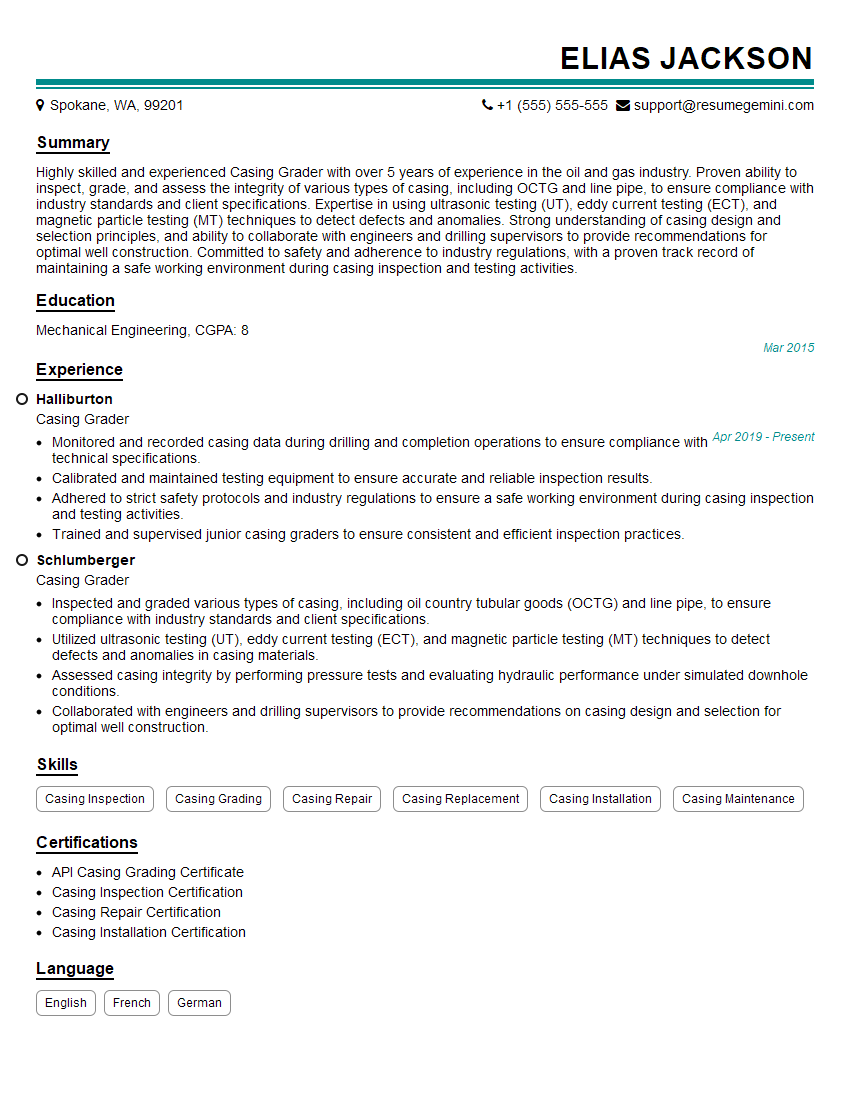

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casing Grader

1. What are the key factors to consider when grading casing?

When grading casing, the following key factors should be considered:

- Wall thickness: The wall thickness of the casing should be sufficient to withstand the pressure and loads it will be subjected to during its service life.

- Diameter: The diameter of the casing should be large enough to accommodate the production tubing and other equipment that will be installed inside it.

- Length: The length of the casing should be long enough to extend from the surface to the bottom of the wellbore.

- Material: The casing should be made of a material that is resistant to corrosion and wear.

- Grade: The grade of the casing should be appropriate for the application.

2. What are the different types of casing?

Types of casing:

- Conductor casing: This is the first casing string that is installed in a wellbore. It is typically made of large-diameter, low-grade steel and is used to protect the wellbore from collapse during drilling.

- Surface casing: This casing string is installed after the conductor casing and is used to protect the wellbore from collapse and fluid invasion.

- Intermediate casing: This casing string is installed after the surface casing and is used to protect the wellbore from collapse and fluid invasion in deeper sections of the wellbore.

- Production casing: This casing string is installed after the intermediate casing and is used to protect the wellbore from collapse and fluid invasion in the production zone.

3. What are the steps involved in grading casing?

The steps involved in grading casing are as follows:

- Visual inspection: The casing is visually inspected for any defects, such as cracks, dents, or corrosion.

- Dimensional inspection: The casing is measured to verify that it meets the specified dimensions.

- Material testing: The casing is tested to verify that it is made of the correct material and that it meets the specified material properties.

- Performance testing: The casing is tested to verify that it meets the specified performance requirements, such as pressure resistance and collapse resistance.

4. What are the consequences of using casing that is not properly graded?

Using casing that is not properly graded can have a number of consequences, including:

- Wellbore collapse: Casing that is not strong enough to withstand the pressure and loads it will be subjected to can collapse, which can lead to the loss of the wellbore and the production fluids.

- Fluid invasion: Casing that is not properly sealed can allow fluid to invade the wellbore, which can contaminate the production fluids and damage the equipment.

- Corrosion: Casing that is not made of a corrosion-resistant material can corrode, which can weaken the casing and lead to failure.

- Equipment damage: Casing that is not properly graded can damage the production tubing and other equipment that is installed inside it.

5. What are the latest trends in casing grading?

The latest trends in casing grading include the following:

- Automated grading: Automated grading systems are being used to improve the accuracy and efficiency of casing grading.

- Non-destructive testing: Non-destructive testing methods are being used to inspect casing without damaging it.

- Remote grading: Remote grading systems are being used to grade casing from a remote location.

- Data-driven grading: Data-driven grading systems are being used to identify trends and patterns in casing grading data.

6. What are the challenges facing casing graders?

Casing graders face a number of challenges, including:

- The increasing demand for casing: The increasing demand for oil and gas is leading to an increase in the demand for casing.

- The need for improved quality control: The increasing demand for casing is leading to a need for improved quality control to ensure that casing meets the required standards.

- The need for new technologies: The increasing demand for casing and the need for improved quality control are leading to a need for new technologies to improve the efficiency and accuracy of casing grading.

7. What are the opportunities for casing graders?

Casing graders have a number of opportunities, including:

- The increasing demand for casing: The increasing demand for oil and gas is leading to an increase in the demand for casing.

- The need for improved quality control: The increasing demand for casing is leading to a need for improved quality control to ensure that casing meets the required standards.

- The need for new technologies: The increasing demand for casing and the need for improved quality control are leading to a need for new technologies to improve the efficiency and accuracy of casing grading.

8. What are the key skills and qualifications for a casing grader?

The key skills and qualifications for a casing grader include:

- A strong understanding of casing design and specifications

- Experience in casing grading and inspection

- Knowledge of non-destructive testing methods

- Ability to work independently and as part of a team

9. What is the future of casing grading?

The future of casing grading is bright. The increasing demand for casing, the need for improved quality control, and the need for new technologies are all driving the development of new and innovative casing grading technologies.

10. What are the challenges in casing grading?

The challenges in casing grading include:

- The increasing demand for casing: The increasing demand for oil and gas is leading to an increase in the demand for casing.

- The need for improved quality control: The increasing demand for casing is leading to a need for improved quality control to ensure that casing meets the required standards.

- The need for new technologies: The increasing demand for casing and the need for improved quality control are leading to a need for new technologies to improve the efficiency and accuracy of casing grading.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casing Grader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casing Grader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Casing Graders play a crucial role in the oil and gas industry, ensuring the quality and integrity of casing used in drilling operations. Their responsibilities encompass a wide range of tasks, including:

1. Casing Inspection and Grading

Casing Graders meticulously inspect casing pipes for defects, flaws, and any irregularities that may compromise their structural integrity. They use various non-destructive testing methods, such as visual inspection, ultrasonic testing, and eddy current testing, to identify anomalies and determine the fitness of the casing for its intended application.

2. Quality Control and Assurance

Maintaining high standards of quality is paramount for Casing Graders. They establish and implement quality control procedures, ensuring that casing meets specifications and industry regulations. They supervise the testing process, analyze results, and prepare reports documenting the findings.

3. Collaboration and Documentation

Casing Graders collaborate closely with other professionals involved in drilling operations, including drilling engineers, field supervisors, and contractors. They effectively communicate inspection results, recommendations, and any potential issues to ensure timely decision-making. Comprehensive documentation of all inspection activities and findings is essential for maintaining an accurate record of the casing’s condition.

4. Training and Supervision

To ensure a skilled workforce, Casing Graders often provide training and supervision to junior inspectors or field personnel. They share their expertise, ensuring that proper inspection techniques and safety protocols are followed.

Interview Tips

Preparing thoroughly for a Casing Grader interview can significantly increase your chances of success. Consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s culture, values, and the specific requirements of the Casing Grader role. Researching the industry’s best practices and recent advancements in casing inspection techniques will demonstrate your commitment and enthusiasm.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in non-destructive testing methods, quality control procedures, and technical reporting. Quantify your accomplishments, using specific examples to showcase your ability to identify and resolve casing-related issues.

3. Prepare for Technical Questions

Anticipate questions related to casing inspection techniques, quality assurance standards, and troubleshooting procedures. Practice explaining your approach to problem-solving and decision-making in the field.

4. Demonstrate Communication and Teamwork Abilities

Casing Graders play a vital role in ensuring effective communication and collaboration among team members. Showcase your ability to clearly articulate technical findings, work effectively in a team environment, and maintain positive relationships with colleagues.

5. Ask Thoughtful Questions

Preparing insightful questions to ask the interviewer demonstrates your interest and engagement in the position. Ask about the company’s commitment to quality, industry trends, or opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Casing Grader interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!