Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Peanut Separator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Peanut Separator so you can tailor your answers to impress potential employers.

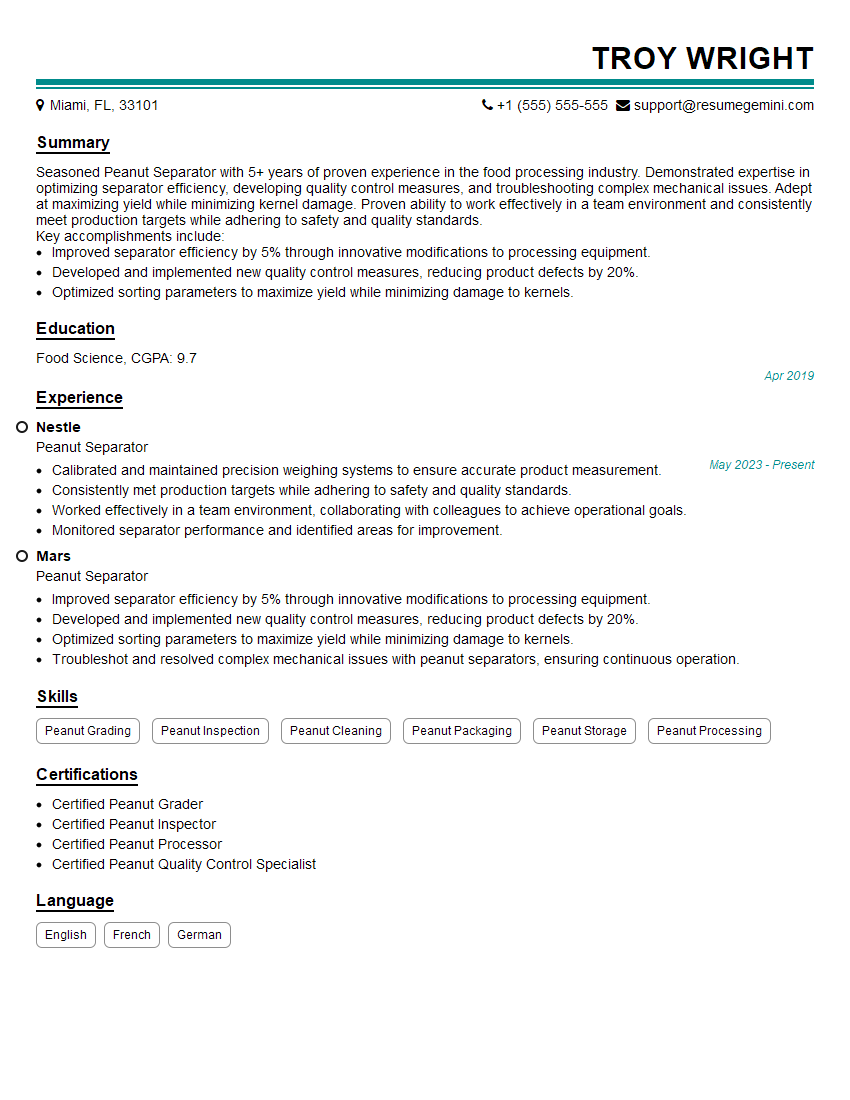

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Peanut Separator

1. As a Peanut Separator, what are the key steps involved in the peanut separation process?

- Receiving and cleaning the peanuts to remove any debris or impurities.

- Sorting the peanuts by size and quality using screens and conveyors.

- Separating the peanuts from their shells using mechanical shelling machines.

- Removing any remaining shells or debris from the peanuts using aspiration systems.

- Grading the peanuts based on size and quality for packaging and distribution.

2. What are the different types of peanut separators available, and how do they work?

Mechanical Separators

- Use rotating cylinders or discs with varying gaps to separate peanuts based on size.

- Can be used for both shelling and sorting.

Aspirator Separators

- Use a stream of air to remove lightweight shells and debris from peanuts.

- Can be used as a post-shelling step to enhance cleaning.

Electronic Separators

- Use sensors to detect and separate peanuts based on color, shape, or other characteristics.

- Provide precise separation for specific applications.

3. What are the common challenges faced in peanut separation, and how do you overcome them?

- Damaged or broken peanuts: Use gentle handling techniques and adjust machine settings to minimize damage.

- Foreign materials: Implement thorough cleaning and inspection processes to remove debris and impurities.

- Inefficient separation: Optimize machine settings, calibrate sensors, and perform regular maintenance to ensure optimal performance.

- Peanut quality variations: Grade peanuts based on size and quality to ensure consistent product specifications.

- Production bottlenecks: Enhance equipment efficiency, streamline processes, and implement automation to increase throughput.

4. What measures can be taken to ensure the quality and safety of peanuts during the separation process?

- Hygiene and sanitation: Maintain a clean and sanitized work environment to prevent contamination.

- Proper handling: Use appropriate equipment and techniques to avoid damaging peanuts.

- Equipment calibration: Calibrate equipment regularly to ensure accurate separation and grading.

- Inspection and sorting: Implement quality control measures to remove any defective or substandard peanuts.

- Traceability: Maintain records and documentation to track the origin and handling of peanuts for safety and quality assurance.

5. How do you maintain and troubleshoot peanut separators to ensure optimal performance?

- Regular maintenance: Follow manufacturer’s recommendations for cleaning, lubrication, and part replacement.

- Troubleshooting: Identify common issues, such as sensor malfunctions or mechanical failures, and implement appropriate solutions.

- Calibration and adjustments: Calibrate sensors and adjust machine settings to optimize separation efficiency and product quality.

- Preventative maintenance: Conduct regular inspections and perform minor repairs to prevent major breakdowns.

- Training: Provide training to operators on proper maintenance and troubleshooting procedures.

6. Are you familiar with the latest advancements and technologies in peanut separation?

- Optical sorting: Uses cameras and sensors to detect and remove peanuts with defects or foreign materials.

- Laser shelling: Utilizes lasers to precisely cut peanut shells, reducing damage and improving efficiency.

- Automation and robotics: Implements automated systems to streamline processes and enhance productivity.

- Data analytics: Collects and analyzes data from sensors and equipment to optimize performance and predict maintenance needs.

- Smart sensors: Monitors temperature, humidity, and other parameters to ensure ideal conditions for peanut storage and handling.

7. How do you ensure the safety of yourself and others while operating peanut separators?

- Follow safety protocols: Adhere to established safety guidelines and procedures.

- Wear appropriate PPE: Use personal protective equipment (PPE), such as gloves, safety glasses, and hearing protection.

- Inspect equipment regularly: Check equipment for any potential hazards or malfunctions before operation.

- Maintain a clean work area: Keep the work area free of debris or obstacles to prevent accidents.

- Be aware of surroundings: Pay attention to other workers and moving machinery to avoid collisions.

8. How do you stay updated with the latest advancements in peanut separation techniques and equipment?

- Attend industry events and conferences: Participate in workshops and presentations to learn about new technologies.

- Read trade publications and online resources: Stay informed through industry magazines and websites.

- Network with other professionals: Connect with peers and experts in the field to exchange knowledge and best practices.

- Seek training and certification: Pursue professional development opportunities to enhance skills and stay current with industry standards.

- Collaborate with equipment manufacturers: Engage with manufacturers to learn about product updates and advanced features.

9. What are the key performance indicators (KPIs) you use to monitor and evaluate the performance of peanut separators?

- Separation efficiency: Percentage of peanuts successfully separated from shells or foreign materials.

- Product quality: Grade and condition of peanuts after separation, meeting desired specifications.

- Throughput: Amount of peanuts processed per unit time, indicating productivity.

- Downtime: Frequency and duration of equipment breakdowns or maintenance.

- Energy consumption: Amount of energy required to operate separators, considering efficiency.

10. How do you handle situations where the peanut separator is not performing optimally?

- Troubleshoot the problem: Identify the cause of underperformance, such as sensor malfunctions or mechanical issues.

- Calibrate and adjust: Make necessary adjustments to sensors and equipment settings to optimize performance.

- Perform maintenance or repairs: Conduct repairs or maintenance tasks to address any faults or wear and tear.

- Contact the manufacturer: Seek assistance from the equipment manufacturer for complex issues or technical support.

- Monitor and evaluate: Observe the separator’s performance after troubleshooting to ensure it meets desired standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Peanut Separator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Peanut Separator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Peanut Separators are responsible for ensuring the quality of peanuts by removing foreign materials, such as dirt, stones, and other debris. They operate and maintain peanut separating machines, which use various methods to separate peanuts from these contaminants.

1. Machine Operation and Maintenance

Peanut Separators must be proficient in operating and maintaining peanut separating machines. This includes:

- Setting up and adjusting the machine according to the type of peanuts being processed.

- Monitoring the machine during operation to ensure it is running smoothly.

- Performing routine maintenance and repairs to keep the machine in good working condition.

2. Quality Control

Peanut Separators are responsible for ensuring the quality of the peanuts being processed. This includes:

- Inspecting peanuts before and after processing to remove any foreign materials.

- Maintaining accurate records of the quality of the peanuts being processed.

- Reporting any quality issues to the supervisor.

3. Safety and Compliance

Peanut Separators must follow all safety procedures and regulations. This includes:

- Wearing appropriate safety gear, such as gloves and earplugs.

- Following lockout/tagout procedures when performing maintenance on the machine.

- Maintaining a clean and organized work area.

Interview Tips

To ace an interview for a Peanut Separator position, it is important to be prepared. Here are a few tips to help you succeed:

1. Research the Company and Position

Before the interview, take some time to research the company and the position you are applying for. This will give you a better understanding of the company’s culture, values, and goals. It will also help you to answer questions about the position and why you are interested in working for the company.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience and qualifications for the position. Be prepared to talk about your previous work experience, your skills, and your education.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Peanut Separator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!