Are you gearing up for an interview for a Liquid Fertilizer Servicer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Liquid Fertilizer Servicer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

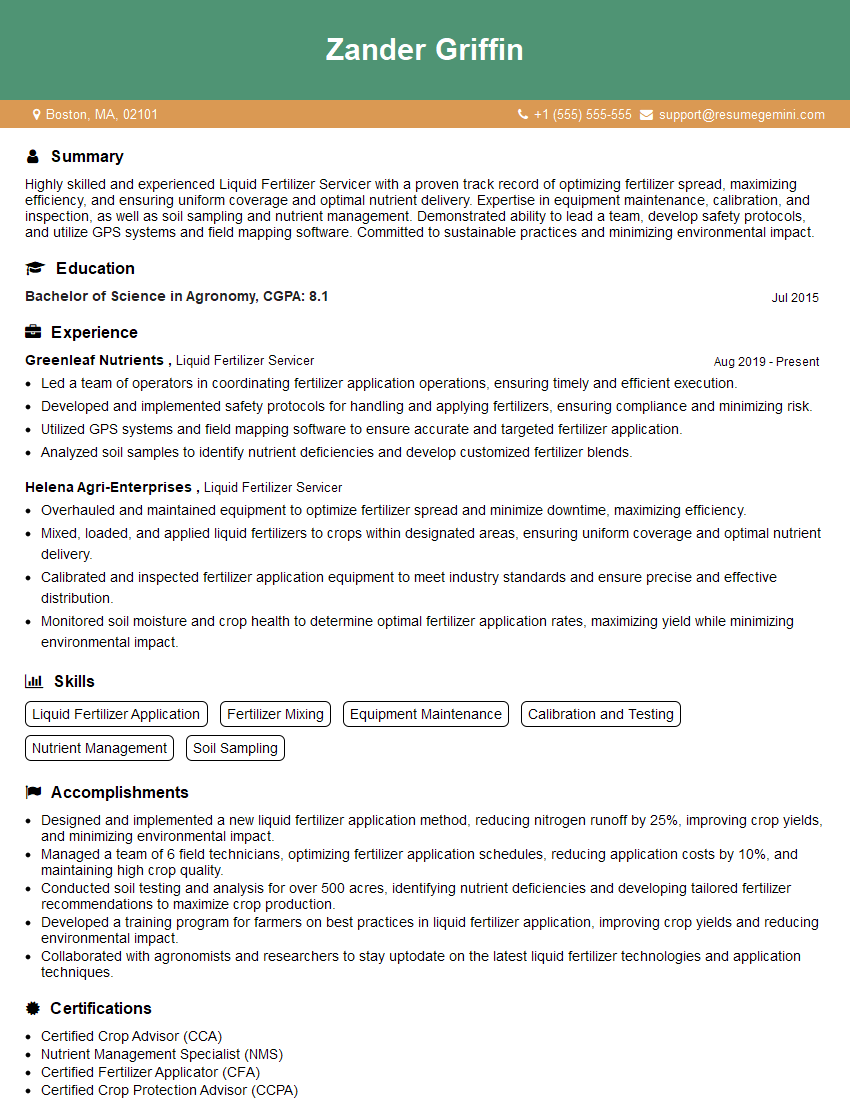

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Liquid Fertilizer Servicer

1. Describe the key responsibilities of a Liquid Fertilizer Servicer.

As a Liquid Fertilizer Servicer, my primary responsibilities include:

- Preparing and calibrating liquid fertilizer application equipment.

- Operating and maintaining fertilizer application systems.

- Monitoring fertilizer application rates and ensuring accuracy.

- Inspecting equipment and identifying potential issues.

- Performing routine maintenance and repairs on equipment.

2. Explain the different types of liquid fertilizers and their application methods.

Nitrogen fertilizers

- Urea-ammonium nitrate (UAN) solution

- Ammonium nitrate (AN) solution

- Aqua ammonia

Phosphate fertilizers

- Ammonium polyphosphate (APP) solution

- Superphosphoric acid (SPA)

Potash fertilizers

- Potassium chloride (KCl) solution

- Potassium nitrate (KNO3) solution

The application method depends on the type of fertilizer, soil conditions, and crop requirements.

3. Discuss the importance of soil testing before applying liquid fertilizers.

Soil testing provides valuable information about:

- Soil pH and nutrient levels

- Crop nutrient requirements

- Fertilizer application rates

By conducting soil tests, we can ensure that the right type and amount of liquid fertilizer is applied, maximizing crop yield and minimizing environmental impact.

4. Explain the calibration process for liquid fertilizer application equipment.

Calibration involves:

- Determining the flow rate of the fertilizer solution

- Adjusting the application rate to match soil test recommendations

- Checking the accuracy of the application system

Proper calibration ensures that fertilizer is applied at the correct rate and uniformity, reducing waste and optimizing crop growth.

5. Describe the safety precautions that must be taken when handling and applying liquid fertilizers.

Liquid fertilizers can be hazardous, so it is essential to follow safety precautions, such as:

- Wearing appropriate personal protective equipment (PPE)

- Storing and handling fertilizers according to manufacturer’s instructions

- Avoiding contact with skin and eyes

- Neutralizing spills and leaks promptly

- Following emergency procedures in case of accidents

6. Explain the factors that affect the efficacy of liquid fertilizer application.

The efficacy of liquid fertilizer application depends on several factors, including:

- Soil conditions (pH, moisture, texture)

- Crop type and growth stage

- Weather conditions (temperature, wind speed)

- Fertilizer type and concentration

- Application method and equipment

Understanding these factors allows for optimizing application practices and maximizing fertilizer effectiveness.

7. Discuss the environmental considerations related to liquid fertilizer application.

Liquid fertilizer application can have environmental implications, such as:

- Nutrient runoff and water pollution

- Greenhouse gas emissions

- Soil acidification

By implementing best management practices, such as controlled application rates, proper timing, and precision farming techniques, we can minimize these environmental impacts.

8. Describe the maintenance and repair procedures for liquid fertilizer application equipment.

Regular maintenance and repair are crucial for ensuring safe and efficient operation of liquid fertilizer application equipment. Common procedures include:

- Inspecting and cleaning equipment before and after use

- Replacing worn or damaged parts

- Calibrating equipment regularly

- Troubleshooting and repairing any malfunctions

Proper maintenance extends the lifespan of equipment, reduces downtime, and ensures accurate fertilizer application.

9. Explain the importance of record-keeping in liquid fertilizer application.

Detailed record-keeping is essential for:

- Tracking fertilizer application rates and timing

- Monitoring crop response and adjusting applications accordingly

- Complying with regulatory requirements

- Evaluating the effectiveness of fertilizer programs

Accurate records provide valuable insights and support informed decision-making in fertilizer management.

10. Describe the emerging technologies used in liquid fertilizer application.

Recent advancements in technology have introduced various innovations, such as:

- GPS-guided application systems for precision farming

- Variable rate technology to adjust application rates based on soil conditions

- Sensors to monitor soil moisture and nutrient levels

- Remote monitoring and control systems for efficient management

These technologies enhance application accuracy, optimize fertilizer use, and improve overall crop productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Liquid Fertilizer Servicer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Liquid Fertilizer Servicer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Liquid Fertilizer Servicers play a crucial role in supporting farmers and ensuring crop health. Their key responsibilities encompass:1. Fertilizer Application and Management

- Operate and maintain liquid fertilizer application equipment to deliver precise quantities of nutrients to crops.

- Monitor soil nutrient levels and adjust fertilizer plans accordingly to optimize crop growth.

- Interpret soil test results and make informed decisions on fertilizer recommendations.

2. Tank Cleaning and Equipment Maintenance

- Clean and maintain fertilizer tanks, equipment, and machinery to ensure efficient operation.

- Perform regular inspections and promptly identify any equipment malfunctions or potential issues.

- Collaborate with the maintenance team to resolve any equipment-related problems.

3. Customer Relations and Coordination

- Establish and maintain relationships with farmers, providing technical guidance and support.

- Coordinate with logistics teams to ensure timely delivery of fertilizer to farmers.

- Handle customer inquiries, resolve issues, and build lasting relationships.

4. Safety and Environmental Compliance

- Adhere to all safety regulations and guidelines related to fertilizer handling and application.

- Take precautions to minimize environmental impact and protect water resources.

- Maintain up-to-date knowledge of industry best practices and regulations.

Interview Preparation Tips

To effectively prepare for an interview as a Liquid Fertilizer Servicer, it is essential to:1. Research the Company and Industry

- Gain a thorough understanding of the company’s mission, values, and commitment to sustainable agriculture.

- Learn about the latest industry trends and technological advancements in liquid fertilizer application.

2. Highlight Relevant Skills and Experience

- Emphasize your proficiency in operating and maintaining liquid fertilizer equipment.

- Showcase your knowledge of soil nutrient management and fertilizer application techniques.

- Stress your ability to work collaboratively with farmers and provide excellent customer service.

3. Prepare for Technical Questions

- Be prepared to discuss your understanding of liquid fertilizer formulations, application rates, and environmental regulations.

- Practice answering questions related to equipment maintenance, safety protocols, and troubleshooting procedures.

- Consider using examples from previous work experiences to demonstrate your technical abilities.

4. Demonstrate Passion and Motivation

- Express your enthusiasm for supporting farmers and ensuring crop health.

- Explain how your values align with the company’s commitment to sustainable agriculture.

- Show that you are eager to contribute your skills and knowledge to the team.

5. Ask Thoughtful Questions

- Prepare questions that demonstrate your interest in the company’s approach to liquid fertilizer services.

- Ask about opportunities for professional development and training.

- Inquire about the company’s commitment to environmental stewardship and sustainability.

Next Step:

Now that you’re armed with the knowledge of Liquid Fertilizer Servicer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Liquid Fertilizer Servicer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini