Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Packing Tractor Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

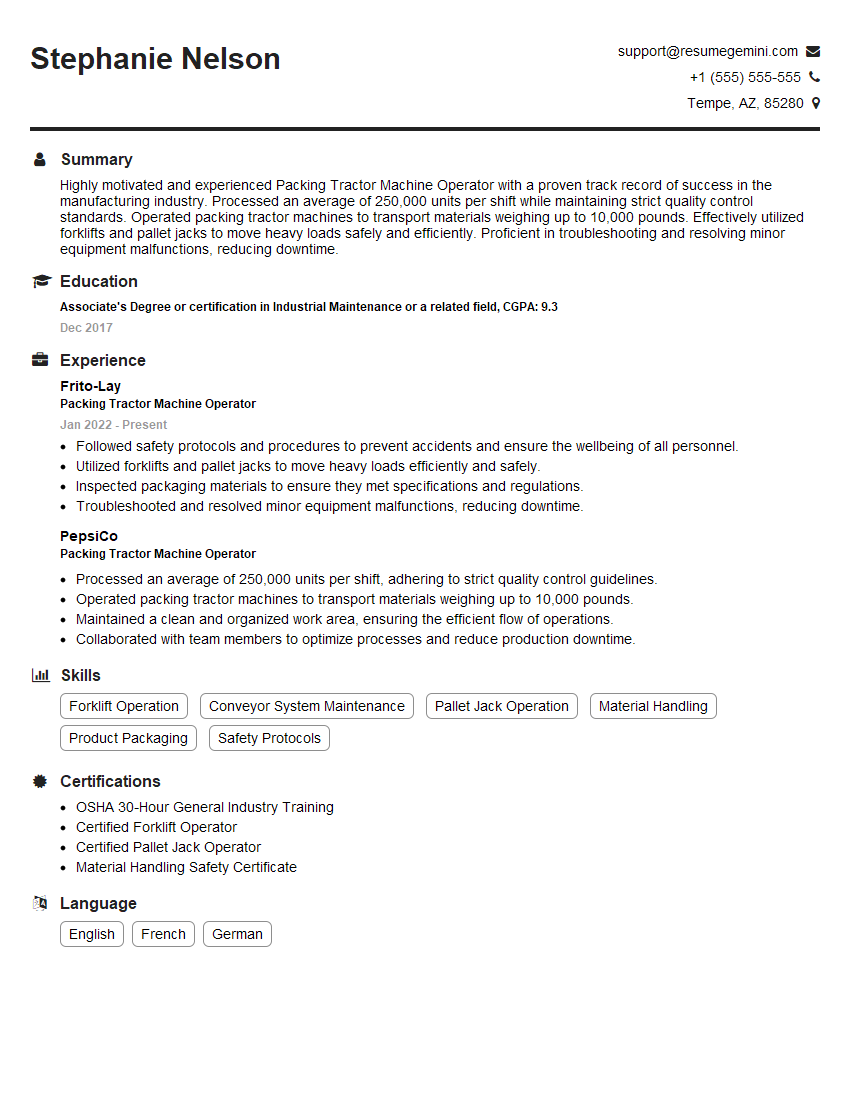

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Packing Tractor Machine Operator

1. What are the different types of packing tractor machines and their uses?

There are several types of packing tractor machines, each designed for specific tasks and applications. Here are the most common types:

- Static Pack Tractors: These machines are used for compacting soil in confined areas, such as around building foundations and roadbeds. They typically have a heavy roller or blade that applies pressure to the ground.

- Tow-Behind Pack Tractors: These machines are towed behind a tractor or other vehicle. They are used for compacting soil in larger areas, such as fields or construction sites.

- Self-Propelled Pack Tractors: These machines are powered by their own engine and have a built-in roller or blade. They are highly versatile and can be used in a variety of applications, including soil compaction, asphalt paving, and snow removal.

2. What are the important safety precautions that need to be followed when operating a packing tractor machine?

Pre-Operation Checks:

- Inspect the machine for any damage or leaks.

- Check the fluid levels (oil, fuel, coolant).

- Ensure that all guards and safety devices are in place and functioning properly.

During Operation:

- Wear appropriate personal protective equipment (PPE), such as a hard hat, safety glasses, and gloves.

- Be aware of your surroundings and keep a safe distance from other people and objects.

- Operate the machine at a safe speed and avoid sudden movements.

- Never leave the machine unattended while it is running.

3. What are the key maintenance tasks that need to be performed on a packing tractor machine?

Regular maintenance is crucial to ensure the optimal performance and longevity of a packing tractor machine. Here are some key maintenance tasks:

- Daily Maintenance: Check fluid levels, inspect for leaks, and clean the machine.

- Weekly Maintenance: Lubricate moving parts, inspect tires, and check the air filter.

- Monthly Maintenance: Change the oil and oil filter, inspect spark plugs, and clean the fuel filter.

- Seasonal Maintenance: Inspect the battery, check the cooling system, and perform a thorough cleaning of the machine.

4. How do you troubleshoot common problems that may arise while operating a packing tractor machine?

- Engine won’t start: Check the battery, fuel supply, and spark plugs.

- Machine is not compacting effectively: Inspect the roller or blade for wear or damage, and check the tire pressure.

- Hydraulic system is not functioning properly: Check the hydraulic fluid level and inspect the hoses and connections for leaks.

- Machine is overheating: Check the coolant level and inspect the radiator for blockages.

5. What is the importance of using the correct tire pressure on a packing tractor machine?

Using the correct tire pressure is critical for the proper operation and safety of a packing tractor machine. Here’s why:

- Soil Compaction: Correct tire pressure helps distribute the weight of the machine evenly, ensuring optimal soil compaction.

- Traction: Proper tire pressure provides adequate traction, preventing the machine from slipping or getting stuck.

- Stability: Using the correct tire pressure enhances the stability of the machine, reducing the risk of rollovers or accidents.

- Tire Life: Maintaining proper tire pressure extends the lifespan of the tires by reducing uneven wear and tear.

6. How do you determine the appropriate compaction depth for different soil types?

The appropriate compaction depth for different soil types varies depending on the soil’s characteristics and the intended use of the compacted area.

- Sandy Soil: Sandy soils require less compaction depth, typically around 6-8 inches.

- Silty Soil: Silty soils require a compaction depth of approximately 8-12 inches.

- Clay Soil: Clay soils need deeper compaction, usually around 12-18 inches.

- Mixed Soils: For mixed soils, the compaction depth should be based on the predominant soil type and the intended use.

7. What factors influence the productivity of a packing tractor machine?

- Machine Condition: A well-maintained machine with sharp blades or rollers will perform better.

- Soil Conditions: Soil type, moisture content, and compaction requirements affect productivity.

- Operator Skill: An experienced operator can maximize efficiency and minimize downtime.

- Site Layout: The layout of the site, including obstacles and access points, can impact productivity.

- Weather Conditions: Adverse weather conditions, such as heavy rain or extreme heat, can slow down operations.

8. How do you ensure that the compacted surface meets the specified density and smoothness requirements?

- Use of Densitometer: A densitometer is used to measure the density of the compacted soil and ensure it meets the specified requirements.

- Visual Inspection: Inspecting the surface for smoothness and any unevenness or voids.

- Proof Rolling: Rolling the surface with a heavy roller or a vibrating plate compactor to achieve the desired smoothness.

- Testing and Adjustments: Conducting field tests, such as plate load tests, to verify the compacted surface meets the specified criteria. Making necessary adjustments based on the test results.

9. How do you handle situations where the ground is too soft or unstable for the packing tractor machine?

- Assess the Situation: Evaluate the ground conditions and determine the extent of softness or instability.

- Use of Geotextiles: Laying down geotextiles or geogrids to provide stability and reinforcement to the ground.

- Phased Compaction: Compacting the ground in multiple passes, starting with lighter passes and gradually increasing the weight and pressure.

- Alternative Methods: Consider using alternative compaction methods, such as vibratory rollers or plate compactors, which may be more suitable for unstable ground.

- Seek Expert Advice: Consult with engineers or geotechnical specialists if necessary to determine the best approach.

10. Describe a situation where you successfully resolved a complex issue related to packing tractor machine operations.

Recently, I encountered an issue where the packing tractor machine was not compacting the soil effectively, resulting in uneven and loose surfaces. After troubleshooting the machine and inspecting the soil conditions, I realized that the soil was too dry and had insufficient moisture content. To resolve this, I coordinated with the water truck operator to provide water to the soil, ensuring optimal moisture conditions. This allowed the packing tractor machine to achieve the desired compaction density and smoothness, meeting the project specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Packing Tractor Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Packing Tractor Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Packing Tractor Machine Operator is responsible for the safe and efficient operation of packing tractors used in agricultural and industrial settings. This role involves a range of duties, including:

1. Tractor Operation

Operate packing tractors to transport goods, equipment, and materials.

- Maintain safe driving practices and adhere to all traffic regulations.

- Inspect tractors regularly to ensure proper operation and safety.

2. Packing and Loading

Load and unload goods onto packing tractors using appropriate equipment and techniques.

- Secure loads using straps, chains, or other restraints.

- Verify the weight and dimensions of loads to ensure safe handling.

3. Equipment Maintenance

Maintain and service packing tractors and associated equipment.

- Perform routine inspections and repairs as needed.

- Lubricate and clean equipment regularly.

4. Communication

Communicate clearly and effectively with supervisors, colleagues, and customers.

- Report any equipment malfunctions or safety concerns promptly.

- Provide updates on work progress and any potential delays.

Interview Tips

To prepare for your interview as a Packing Tractor Machine Operator, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s website, industry, and the specific responsibilities of the Packing Tractor Machine Operator role.

- Highlight any relevant skills and experience that align with the job requirements.

- Demonstrate your understanding of the industry and the importance of this role within the organization.

2. Practice Your Answers

Prepare thoughtful answers to common interview questions, such as:

- “Tell me about your experience operating packing tractors.”

- “Describe a situation where you overcame a challenge related to packing or loading.”

- “How do you prioritize tasks and manage your time effectively?”

- “What are your safety protocols when operating heavy machinery?”

3. Emphasize Your Skills

Highlight your relevant skills, abilities, and certifications, such as:

- Tractor operation and maintenance experience

- Expertise in packing and loading techniques

- Knowledge of safety protocols and regulations

- Strong communication and teamwork skills

4. Prepare Questions

Asking thoughtful questions at the end of the interview shows your interest and engagement.

- “Could you elaborate on the company’s safety policies?”

- “What are the opportunities for professional development within this role?”

- “Can you describe the work environment and culture of the organization?”

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Packing Tractor Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Packing Tractor Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.