Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Binder Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Binder Operator so you can tailor your answers to impress potential employers.

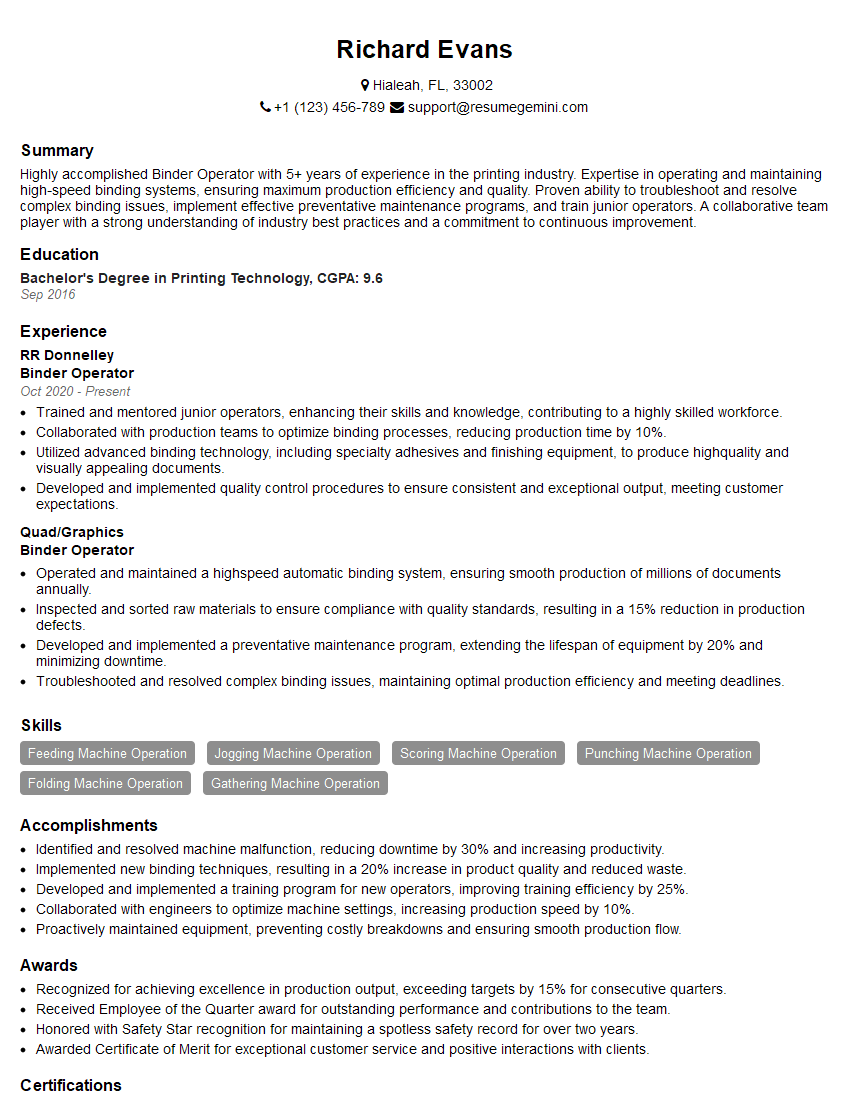

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Binder Operator

1. What knowledge do you have about Binder Operator?

A binder operator is a skilled professional responsible for operating binder machines used in the production of books, magazines, and other printed materials. The role involves various tasks, including setting up and operating binder machines, maintaining equipment, ensuring the quality of finished products, and following safety protocols.

2. What are the key responsibilities of a Binder Operator?

Setting up and operating binder machines

- Preparing and loading materials into the binder machine.

- Adjusting machine settings to meet specific binding requirements.

- Monitoring the binding process to ensure smooth operation.

Maintaining equipment

- Performing regular maintenance checks and cleaning of binder machines.

- Identifying and troubleshooting any malfunctions or issues.

- Coordinating with maintenance personnel for repairs and replacements.

Ensuring product quality

- Inspecting finished products to ensure they meet quality standards.

- Identifying and correcting any defects or errors.

- Maintaining a clean and organized work area.

Following safety protocols

- Adhering to established safety guidelines and procedures.

- Wearing appropriate personal protective equipment (PPE).

- Reporting any safety concerns or incidents immediately.

3. What qualities should an ideal Binder Operator possess?

- Strong attention to detail and accuracy.

- Mechanical aptitude and ability to operate and maintain machinery.

- Physical ability to stand for extended periods and lift heavy materials.

- Excellent communication and interpersonal skills.

- Ability to work independently and as part of a team.

- Willingness to learn and adapt to new technologies and processes.

4. What are the common types of binding machines used in the industry?

- Saddle stitchers: Used for binding booklets, magazines, and catalogs.

- Perfect binders: Used for binding hardcover books and other high-quality publications.

- Spiral binders: Used for binding notebooks, planners, and calendars.

- Comb binders: Used for binding presentations, reports, and other documents.

- Plastic coil binders: Used for binding documents that require frequent page insertions or removals.

5. What are the key factors to consider when selecting the right binding method?

- Type of document being bound (e.g., booklet, book, presentation).

- Number of pages and thickness of the document.

- Desired durability and longevity of the binding.

- Budget and cost considerations.

- Equipment and materials available.

6. How do you ensure the quality of finished products?

- Inspecting materials before use to identify any defects or damage.

- Following established binding procedures and specifications.

- Using precision measuring tools to ensure accuracy.

- Regularly calibrating and maintaining equipment.

- Conducting quality control checks throughout the binding process.

7. What safety precautions should be taken when operating binder machines?

- Wearing appropriate PPE, including safety glasses, gloves, and earplugs.

- Keeping hands and loose clothing away from moving parts.

- Ensuring that guards and safety devices are in place and functioning properly.

- Reporting any unsafe conditions or equipment malfunctions immediately.

- Following established lockout/tagout procedures.

8. What troubleshooting steps would you take if a binder machine malfunctions?

- Identifying the nature of the malfunction (e.g., mechanical, electrical).

- Checking for loose connections, worn parts, or other obvious issues.

- Referring to the machine’s manual or technical documentation for guidance.

- Contacting a maintenance technician if the issue cannot be resolved independently.

- Documenting the malfunction and any troubleshooting steps taken.

9. How do you stay up-to-date on the latest binding technologies and best practices?

- Attending industry conferences and workshops.

- Reading trade publications and technical articles.

- Consulting with equipment manufacturers and suppliers.

- Participating in online forums and discussion groups.

- Seeking feedback from colleagues and supervisors.

10. What are your career goals and aspirations?

I am eager to secure a position as a Binder Operator where I can contribute my skills and experience to the success of your organization. I am passionate about the printing and binding industry, and I am committed to delivering high-quality products and services. In the long term, I aspire to advance my career by taking on leadership roles and responsibilities within the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Binder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Binder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Binder Operators are responsible for the operation and maintenance of binding equipment in a printing or manufacturing environment. Their key responsibilities include:

1. Binding Equipment Operation

Operate a variety of binding equipment, including saddle stitchers, perfect binders, and wire-o binding machines.

- Set up and adjust equipment according to specifications.

- Monitor equipment during operation and make necessary adjustments.

2. Material Handling

Handle and prepare materials for binding, including paper, covers, and adhesives.

- Load and unload materials onto and from equipment.

- Inspect materials for defects.

3. Quality Control

Inspect finished products for quality and accuracy.

- Identify and correct defects.

- Maintain quality standards throughout the binding process.

4. Maintenance and Repair

Perform basic maintenance and repairs on binding equipment.

- Clean and lubricate equipment.

- Identify and troubleshoot problems.

Interview Tips

To ace your interview for a Binder Operator position, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest and knowledge of the company and the printing or manufacturing industry. Research the company’s products, services, and recent news.

- Visit the company website and social media pages.

- Read industry publications and articles.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job responsibilities of a Binder Operator. Quantify your accomplishments whenever possible.

- Highlight your experience operating binding equipment, handling materials, and ensuring quality.

- Provide examples of how you have troubleshoot and resolved problems with binding equipment.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers. This will help you feel more confident and articulate during the interview.

- Tell me about your experience operating binding equipment.

- How do you ensure the quality of finished products?

- Describe a time when you had to troubleshoot a problem with binding equipment.

4. Ask Thoughtful Questions

Ask thoughtful questions at the end of the interview to demonstrate your interest and engagement.

- What are the company’s growth plans for the future?

- What opportunities are there for professional development within the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Binder Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!