Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hammer Mill Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

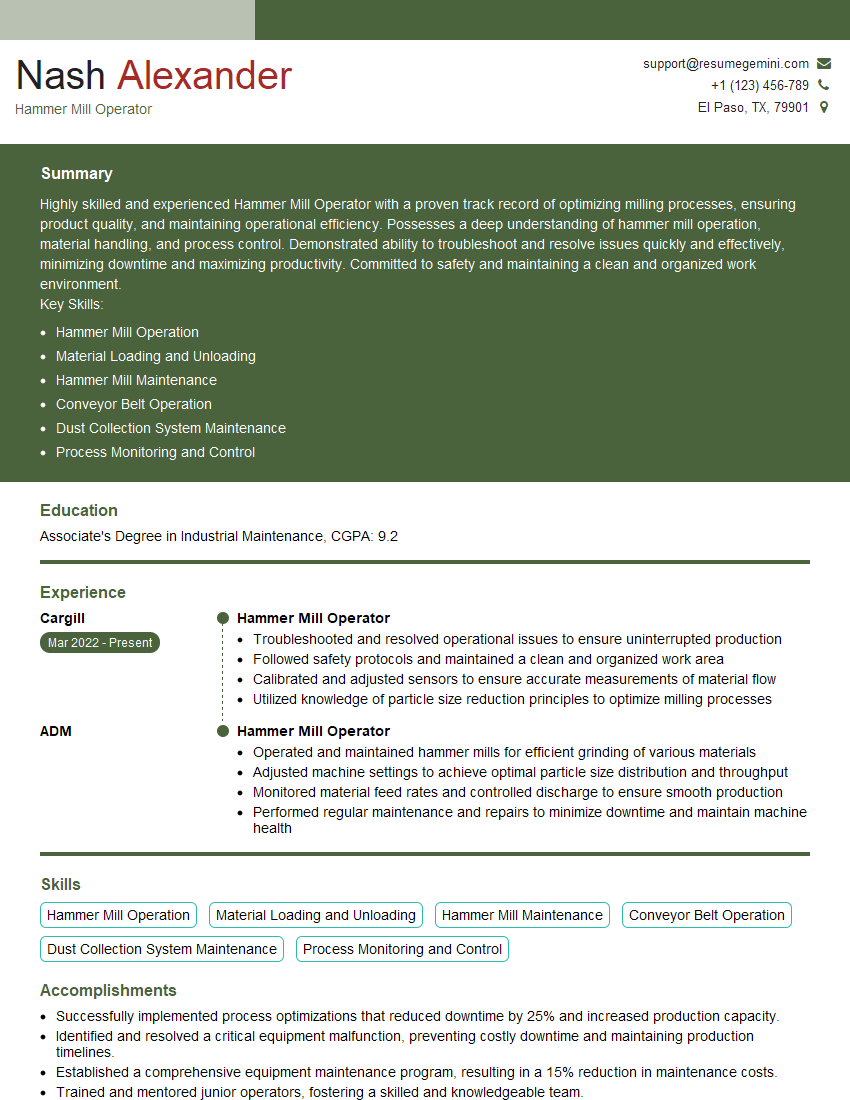

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hammer Mill Operator

1. Describe the key responsibilities of a Hammer Mill Operator?

As a Hammer Mill Operator, my primary responsibilities include:

- Operating and maintaining the hammer mill to reduce materials to the desired size

- Monitoring the mill’s performance and adjusting settings as needed to optimize efficiency and product quality

- Ensuring the mill is operated safely and in compliance with all applicable regulations

- Troubleshooting and resolving any issues that may arise during operation

- Maintaining a clean and organized work area

2. What are the safety protocols that you follow when operating a Hammer Mill?

Safe Operation Procedures

- Wear appropriate personal protective equipment (PPE) such as safety glasses, earplugs, and gloves

- Ensure the mill is properly guarded and all access points are closed

- Lock out and tag out the mill before performing any maintenance or repairs

- Follow proper lockout/tagout procedures

- Never operate the mill with unguarded access points or missing safety devices

Emergency Procedures

- In case of an emergency, immediately shut down the mill and evacuate the area

- Notify the supervisor and appropriate personnel

- Do not attempt to re-enter the area or restart the mill until authorized

3. How do you determine the optimal hammer mill settings for different materials?

The optimal hammer mill settings depend on the material being processed. Factors I consider include:

- Material hardness and size: Harder and larger materials require smaller screen openings and higher impact forces

- Desired product size: Smaller product sizes require smaller screen openings and lower impact forces

- Throughput rate: Higher throughput rates may require larger screen openings and higher impact forces

- Hammer type: Different hammer designs impart different impact forces and can affect product quality

- Screen type: Different screen materials and openings can influence the final product size and shape

I start with a baseline setting and then adjust the mill parameters based on the results obtained during trial runs.

4. What are the common maintenance tasks that you perform on a Hammer Mill?

- Daily: Check and adjust belts, lubricate bearings, clean screens

- Weekly: Replace hammers, inspect screens for damage, clean dust collector

- Monthly: Inspect drive components, check alignment, calibrate sensors

- Quarterly: Perform a thorough inspection of the entire mill, including electrical components and safety devices

- Annually: Schedule a major overhaul to replace worn or damaged parts and ensure optimal performance

5. How do you troubleshoot and resolve a clogged Hammer Mill?

- Check the material feed rate and adjust it if necessary

- Inspect the screens for clogging or damage and clean or replace as needed

- Examine the hammers for wear or damage and replace them if required

- Ensure the mill is properly adjusted and that the hammers are not making contact with the casing

- Check the discharge chute for blockages and clear any obstructions

- If the problem persists, check the power supply, motor, and drive components

6. Describe your experience in calibrating and maintaining Hammer Mill sensors?

I have experience in calibrating and maintaining various sensors used in Hammer Mills, including:

- Temperature sensors: Calibrated using a temperature probe or infrared thermometer

- Vibration sensors: Calibrated using a vibration analyzer

- Proximity sensors: Calibrated using a non-contact sensor or feeler gauge

- Pressure sensors: Calibrated using a pressure gauge or transducer

- Flow sensors: Calibrated using a flowmeter or stopwatch

I ensure that the sensors are properly installed, wired, and calibrated according to manufacturer’s specifications.

7. How do you handle variations in material feed rate and consistency?

Variations in material feed rate and consistency can affect the performance of the Hammer Mill. I handle these situations by:

- Adjusting the mill settings: Modifying the screen openings, hammer impact, or feed rate to accommodate the changing material characteristics

- Monitoring the mill’s performance: Regularly checking product quality, power consumption, and vibration levels to detect any changes

- Communicating with upstream and downstream processes: Coordinating with other departments to ensure a consistent supply of material and to adjust production schedules as needed

8. What is your approach to improving the efficiency of a Hammer Mill operation?

- Optimize mill settings: Determine the optimal combination of hammer impact, screen size, and feed rate to maximize throughput and product quality

- Regular maintenance: Perform scheduled maintenance tasks to prevent breakdowns and ensure the mill is operating at peak efficiency

- Operator training: Provide training to operators on proper operating procedures and maintenance techniques to minimize downtime and improve productivity

- Data analysis: Monitor and analyze mill performance data to identify areas for improvement and implement changes to enhance efficiency

9. How do you ensure the quality of the final product produced by the Hammer Mill?

- Regular product testing: Conduct regular sampling and testing of the final product to ensure it meets the desired specifications

- Process monitoring: Continuously monitor the mill’s performance, including feed rate, product size, and power consumption, to detect any отклонения

- Preventive maintenance: Perform regular maintenance tasks to prevent breakdowns and ensure the mill is operating correctly

- Corrective action: Implement corrective actions promptly to address any identified quality issues and maintain product consistency

10. How do you handle operating the Hammer Mill in a safe and compliant manner?

- Follow safety protocols: Adhere strictly to established safety procedures, including wearing PPE, lockout/tagout, and following emergency evacuation plans

- Maintain a clean and organized work area: Keep the mill and surrounding area free of debris and potential hazards

- Monitor equipment regularly: Regularly inspect the mill for any signs of damage, wear, or leaks

- Report any issues promptly: Notify the supervisor or maintenance personnel immediately if any safety concerns or equipment issues are identified

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hammer Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hammer Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hammer Mill Operators are responsible for the safe and efficient operation of hammer mills, which are used to grind materials such as wood, metal, and plastic into smaller pieces. Key job responsibilities include:

1. Operating the hammer mill

This includes starting, stopping, and adjusting the mill to ensure that it is operating at the correct speed and settings. Operators must also be able to identify and troubleshoot any problems that may occur with the mill.

- Starting, stopping, and adjusting the mill to ensure that it is operating at the correct speed and settings.

- Monitoring the mill’s operation and making adjustments as needed.

- Identifying and troubleshooting any problems that may occur with the mill.

2. Feeding materials into the mill

Operators must ensure that the materials are fed into the mill at a consistent rate to prevent the mill from becoming overloaded or underloaded. They must also be able to identify and remove any foreign objects that may enter the mill.

- Ensuring that the materials are fed into the mill at a consistent rate.

- Identifying and removing any foreign objects that may enter the mill.

3. Maintaining the mill

Operators must perform regular maintenance on the mill to ensure that it is operating safely and efficiently. This includes cleaning the mill, lubricating the bearings, and inspecting the hammers for wear and tear.

- Cleaning the mill.

- Lubricating the bearings.

- Inspecting the hammers for wear and tear.

4. Ensuring the safety of the work area

Operators must follow all safety procedures and wear appropriate personal protective equipment (PPE) when working with the hammer mill. They must also be aware of the potential hazards associated with the mill and take steps to prevent accidents.

- Following all safety procedures.

- Wearing appropriate personal protective equipment (PPE).

- Being aware of the potential hazards associated with the mill.

- Taking steps to prevent accidents.

Interview Tips

To ace the interview for a Hammer Mill Operator position, it is important to be prepared and to highlight your skills and experience that are relevant to the job. Here are some interview tips:

1. Research the company and the position

This will help you to understand the company’s culture and the specific requirements of the position. You can research the company’s website, read articles about the company, and talk to people who work for the company.

- Visit the company’s website.

- Read articles about the company.

- Talk to people who work for the company.

2. Practice your answers to common interview questions

This will help you to feel more confident and prepared during the interview. Some common interview questions that you may be asked include:

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

3. Prepare questions to ask the interviewer

This shows that you are interested in the position and that you have done your research. Some good questions to ask the interviewer include:

- “What are the biggest challenges facing the company right now?”

- “What is the company’s culture like?”

- “What are the opportunities for advancement?”

4. Dress professionally and arrive on time for the interview

This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Dress professionally.

- Arrive on time for the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hammer Mill Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.