Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Poultry Cleaner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

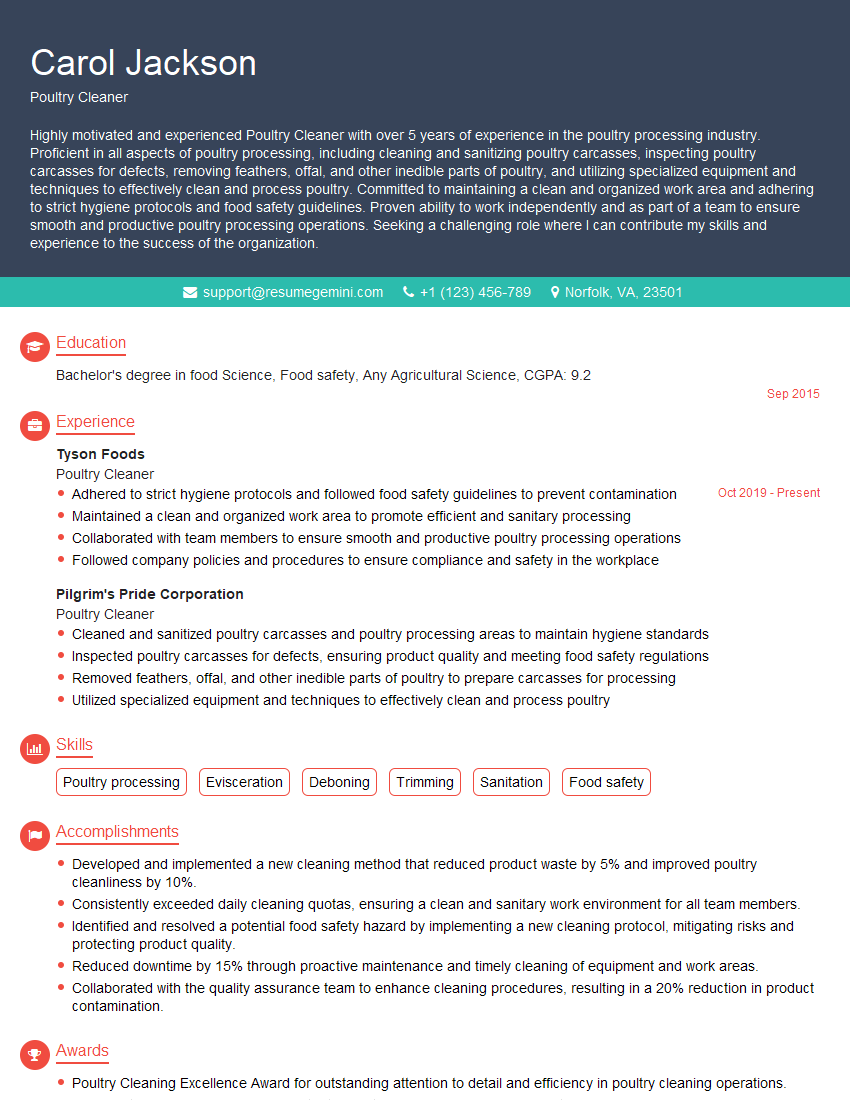

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Poultry Cleaner

1. What are the different types of cleaning methods used in poultry processing plants?

The following are the different types of cleaning methods used in poultry processing plants:

- Manual Cleaning

- Mechanical Cleaning

- Chemical Cleaning

- Combinations of these methods

2. What are the benefits of using a high-pressure washer for cleaning poultry processing equipment?

Benefits

- High-pressure washers can remove dirt, grease, and other contaminants from surfaces quickly and efficiently.

- High-pressure washers can help to prevent the growth of bacteria and other microorganisms on surfaces.

- High-pressure washers can help to improve the overall sanitation of a poultry processing plant.

3. What are the safety precautions that must be taken when using a high-pressure washer?

The following are the safety precautions that must be taken when using a high-pressure washer:

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Never point the high-pressure washer at another person.

- Keep the high-pressure washer away from electrical cords and outlets.

- Do not use the high-pressure washer on surfaces that are not able to withstand the pressure.

4. What are the different types of chemicals that can be used to clean poultry processing equipment?

The following are the different types of chemicals that can be used to clean poultry processing equipment:

- Chlorine

- Iodine

- Potassium permanganate

- Hydrogen peroxide

- Peracetic acid

5. What are the factors that should be considered when selecting a chemical cleaner for poultry processing equipment?

The following are the factors that should be considered when selecting a chemical cleaner for poultry processing equipment:

- The type of equipment being cleaned

- The severity of the contamination

- The desired results

- The safety of the cleaner

- The cost of the cleaner

6. What are the steps involved in developing a cleaning and sanitation program for a poultry processing plant?

The following are the steps involved in developing a cleaning and sanitation program for a poultry processing plant:

- Identify the areas of the plant that need to be cleaned and sanitized

- Determine the frequency of cleaning and sanitizing

- Select the appropriate cleaning and sanitizing agents

- Develop written procedures for cleaning and sanitizing

- Train employees on the cleaning and sanitizing procedures

- Monitor the cleaning and sanitizing program to ensure that it is effective

7. What are the challenges of maintaining a clean and sanitary environment in a poultry processing plant?

The following are the challenges of maintaining a clean and sanitary environment in a poultry processing plant:

- The high volume of poultry that is processed

- The presence of blood, feathers, and other contaminants

- The warm and humid environment

- The potential for cross-contamination

8. What are the benefits of using a HACCP program in a poultry processing plant?

The following are the benefits of using a HACCP program in a poultry processing plant:

- Improved food safety

- Reduced risk of product recalls

- Increased customer confidence

- Improved efficiency and productivity

9. What are the key elements of a HACCP program?

The following are the key elements of a HACCP program:

- Hazard analysis

- Critical control points

- Critical limits

- Monitoring procedures

- Corrective actions

- Verification procedures

- Documentation

10. What is the role of the Poultry Cleaner in a HACCP program?

The Poultry Cleaner plays a vital role in a HACCP program by ensuring that the equipment used in the processing of poultry is clean and sanitary. This helps to prevent the contamination of poultry products with bacteria and other harmful microorganisms.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Poultry Cleaner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Poultry Cleaner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Poultry Cleaners play a crucial role in ensuring a safe and sanitary environment within poultry processing facilities. Their key responsibilities include:

1. Cleaning and Disinfection

Meticulously cleaning and disinfecting equipment, surfaces, and work areas to prevent the spread of disease and maintain hygiene standards.

- Using approved cleaning agents and sanitizing solutions

- Thoroughly cleaning and sanitizing poultry processing equipment, vehicles, and utensils

2. Waste Removal

Efficiently removing and disposing of poultry waste, including feathers, offal, and blood, to prevent contamination and maintain a clean environment.

- Operating and maintaining waste removal systems

- Complying with environmental regulations for waste disposal

3. Equipment Maintenance

Regularly inspecting and maintaining poultry processing equipment to ensure optimal functioning and prevent breakdowns.

- Cleaning and lubricating equipment

- Performing minor repairs and reporting major issues to supervisors

4. Sanitation Monitoring

Monitoring and maintaining sanitation standards throughout the facility, including temperature controls and water quality.

- Testing and monitoring sanitation levels

- Identifying and reporting any deviations from established standards

Interview Tips

To ace the interview for a Poultry Cleaner position, candidates should prepare thoroughly and demonstrate their understanding of the job’s responsibilities and the industry.

1. Research the Poultry Industry

Familiarize yourself with the poultry processing industry, including its regulations and best practices. This knowledge will help you understand the context of the job and the company’s expectations.

- Read industry publications and attend relevant events

- Visit poultry processing facilities (if possible) to observe operations

2. Highlight Cleaning Experience

Emphasize your experience in cleaning and sanitation, particularly in food processing or healthcare settings. Provide specific examples of your work and highlight your attention to detail and ability to maintain high hygiene standards.

- Quantify your achievements whenever possible, using specific metrics

- Be prepared to discuss your understanding of cleaning chemicals and their proper usage

3. Demonstrate Physical Ability

Poultry Cleaner work can be physically demanding. Be prepared to demonstrate your physical stamina and ability to perform repetitive tasks for extended periods.

- Discuss your experience with heavy lifting, standing for long hours, and working in humid environments

- Mention any relevant certifications or training in physical fitness or ergonomics

4. Show Commitment to Safety

Emphasize your commitment to workplace safety and your understanding of the potential hazards in a poultry processing facility.

- Explain your experience with personal protective equipment (PPE), such as gloves, masks, and aprons

- Be prepared to discuss your knowledge of poultry-specific safety regulations and protocols

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and your preparation. Consider questions about the company’s sustainability practices, employee training opportunities, or industry trends.

- Avoid generic questions or ones that can be easily answered by researching the company

- Prepare questions that show your genuine curiosity and enthusiasm for the role

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Poultry Cleaner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!