Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Carbider position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

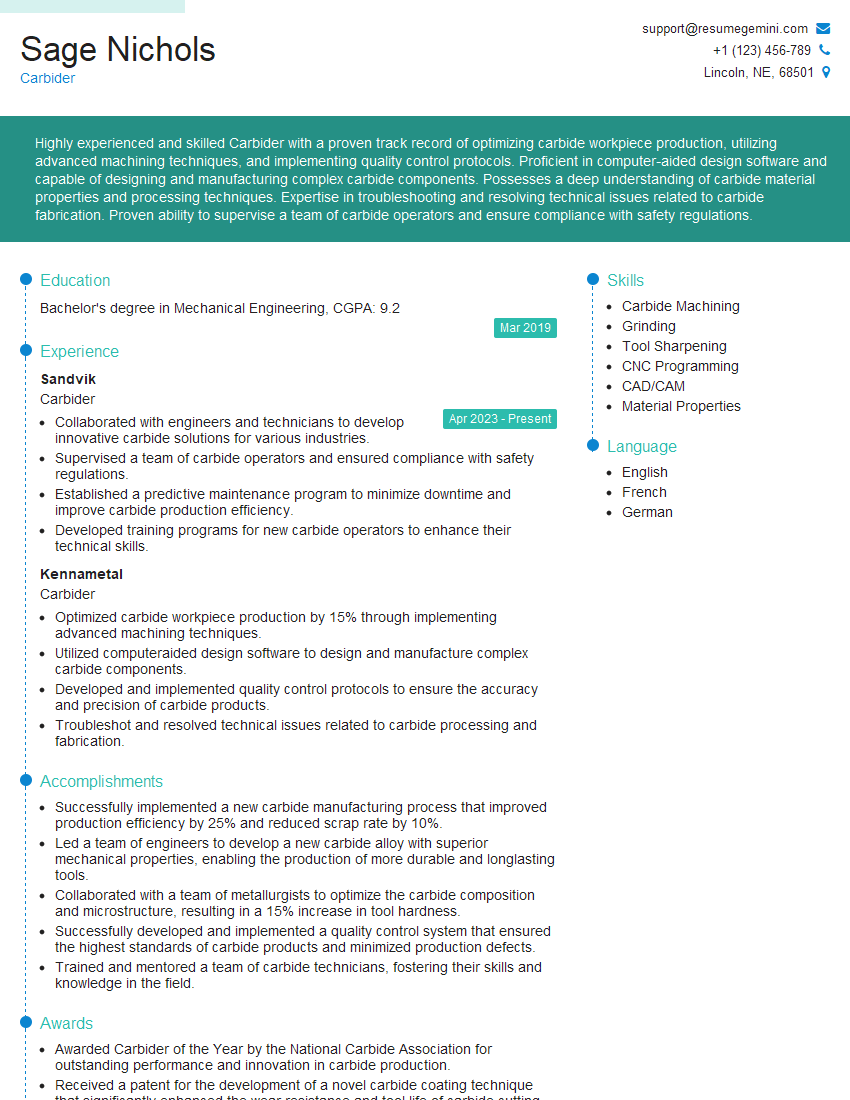

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carbider

1. What is carbide?

Carbides are a class of binary compounds containing carbon and a less electronegative element, usually a metal. Carbides are typically hard, high-melting-point materials, and are often used in cutting tools, abrasives, and wear-resistant coatings.

2. What are the different types of carbides?

Transition metal carbides

- These are the most common type of carbides, and they are formed between carbon and a transition metal. Examples include tungsten carbide (WC), titanium carbide (TiC), and tantalum carbide (TaC).

Main-group metal carbides

- These are formed between carbon and a main-group metal. Examples include silicon carbide (SiC) and boron carbide (B4C).

Actinide and lanthanide carbides

- These are formed between carbon and an actinide or lanthanide element. Examples include uranium carbide (UC) and plutonium carbide (PuC).

3. What are the properties of carbides?

- High hardness and wear resistance

- High melting point

- Good thermal conductivity

- Low coefficient of thermal expansion

- Chemically inert

4. What are the applications of carbides?

- Cutting tools

- Abrasives

- Wear-resistant coatings

- High-temperature materials

- Nuclear fuel

5. How are carbides produced?

- Carbothermic reduction

- Direct synthesis

- Chemical vapor deposition

- Physical vapor deposition

6. What are the challenges in carbide production?

- High temperatures required for synthesis

- Control of stoichiometry

- Prevention of impurities

- Sintering and densification

7. What are the latest developments in carbide research?

- Development of new carbide compositions with improved properties

- Exploration of novel synthesis methods

- Investigation of carbide applications in emerging technologies

8. What are the challenges in carbide research?

- Understanding the fundamental properties of carbides

- Developing new methods for synthesis and processing

- Exploring the potential applications of carbides in various fields

9. What are the trends in carbide research?

- Development of new carbide materials with tailored properties

- Exploration of sustainable synthesis methods

- Integration of carbides with other materials for enhanced performance

10. What are the future prospects for carbide research?

- Continued development of new carbide materials

- Exploration of novel synthesis and processing techniques

- Identification of new applications for carbides in various fields

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carbider.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carbider‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Carbider, your primary focus will be on operating and maintaining carbide production machinery, ensuring efficient and safe production of carbide products.

1. Carbide Production

Operate carbide production furnaces, including electric arc furnaces and induction furnaces, to produce high-quality carbide products.

- Monitor furnace temperatures, feed rates, and other process parameters to optimize carbide yield.

- Control cooling and quenching processes to obtain desired carbide properties.

2. Equipment Maintenance

Perform preventive maintenance and repairs on carbide production machinery, including furnaces, conveyors, and cooling systems.

- Troubleshoot and resolve equipment malfunctions to minimize downtime.

- Coordinate with mechanics and electricians for major repairs and overhauls.

3. Quality Control

Monitor the quality of carbide products, ensuring compliance with specifications and customer requirements.

- Conduct physical and chemical testing of carbide samples to assess their properties.

- Document and maintain quality control records for traceability and compliance.

4. Safety and Environmental Compliance

Follow all safety protocols and procedures related to carbide production and handling.

- Operate equipment safely and wear appropriate personal protective equipment (PPE).

- Monitor environmental emissions and comply with regulatory standards.

Interview Preparation Tips

To prepare for your interview as a Carbider, consider the following tips:

1. Understand the Industry

Familiarize yourself with the carbide production industry, its processes, and the different types of carbide products.

- Research the company you are interviewing with and their specific carbide production methods.

- Read industry articles and attend webinars to stay up-to-date on the latest technologies and trends.

2. Highlight Your Technical Skills

Emphasize your technical knowledge and skills in operating carbide production equipment.

- Provide specific examples of your experience in operating and maintaining carbide furnaces.

- Discuss your understanding of process parameters and quality control techniques.

3. Demonstrate Safety Awareness

Stress your commitment to safety and compliance in the workplace.

- Explain your knowledge of safety protocols and PPE requirements.

- Share examples of how you have implemented safety measures in previous roles.

4. Emphasize Teamwork and Communication

Highlight your ability to work effectively as part of a team and communicate clearly.

- Describe your experience in collaborating with colleagues and supervisors.

- Provide examples of how you effectively communicated technical information to both technical and non-technical audiences.

5. Prepare for Common Interview Questions

Research common interview questions for carbide positions and prepare thoughtful answers.

- Be ready to discuss your experience in operating different types of carbide production furnaces.

- Prepare examples of how you have resolved equipment issues and ensured product quality.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Carbider interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.