Are you gearing up for a career in Chute Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Chute Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

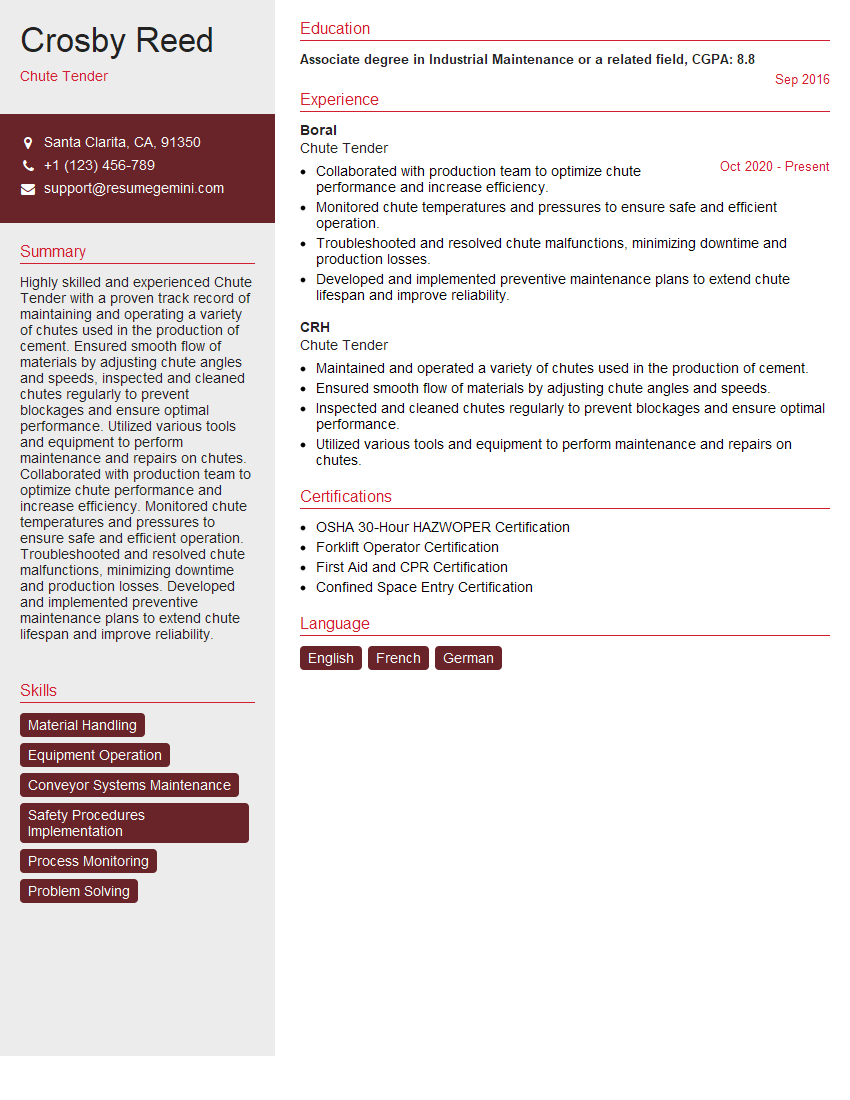

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chute Tender

1. Explain the key responsibilities of a Chute Tender?

As a Chute Tender, I would be responsible for:

- Operating and maintaining chute systems to ensure smooth material flow

- Monitoring and controlling material levels in chutes to prevent blockages or overloads

- Identifying and resolving chute malfunctions promptly to minimize downtime

- Performing routine maintenance and repairs on chute components such as belts, rollers, and supports

- Collaborating with other plant personnel to ensure efficient material handling operations

2. How would you approach optimizing the performance of a chute system?

Ensuring Proper Material Flow

- Inspecting chutes regularly for wear and tear

- Adjusting chute angles and flow rates to minimize friction and blockages

- Utilizing anti-stick materials or coatings to reduce material buildup

Monitoring and Controlling Material Levels

- Installing level sensors to provide real-time data on material levels

- Using automated control systems to adjust chute speeds based on material demand

- Implementing vibration or impact sensors to detect potential blockages

Predictive Maintenance and Troubleshooting

- Performing regular inspections and lubrication of chute components

- Using vibration analysis or thermal imaging to identify potential problems early

- Developing troubleshooting procedures for common chute issues

3. Describe the safety procedures you would follow when operating chute systems?

Safety is paramount in my approach to chute operations. I would adhere to the following procedures:

- Wearing appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection

- Inspecting chutes thoroughly before starting operations, checking for any potential hazards

- Maintaining a safe work area around chutes, ensuring there are no tripping or slipping hazards

- Never entering chutes while they are in operation or under maintenance

- Using lockout/tagout procedures to prevent accidental starts during maintenance or repairs

4. How would you handle a situation where a chute becomes blocked or overloaded?

In the event of a chute blockage or overload:

- Identify and isolate the affected chute

- Attempt to clear the blockage using non-invasive methods such as vibration or tapping

- If non-invasive methods fail, shut down the chute and inspect it for any damage or foreign objects

- Clear the blockage or remove foreign objects, taking precautions to prevent material spillage

- Restart the chute and monitor it closely to ensure proper material flow

5. What maintenance tasks would you perform on chute systems to ensure their longevity?

To ensure the longevity of chute systems, I would perform the following maintenance tasks:

- Regularly inspect chutes for wear and tear, including belts, rollers, and support structures

- Lubricate moving parts to minimize friction and wear

- Clean and remove material buildup from chutes to prevent blockages

- Replace worn or damaged components promptly to prevent failures

- Use corrosion-resistant materials and coatings to extend the lifespan of chutes

6. How would you communicate with other plant personnel about chute performance and maintenance needs?

Communication is crucial for maintaining efficient chute operations. I would:

- Provide regular updates on chute performance to supervisors and maintenance teams

- Report any potential or actual chute issues promptly to initiate timely repairs

- Coordinate with other departments, such as production and engineering, to ensure smooth material flow throughout the plant

- Participate in safety meetings and training programs to share knowledge and best practices

7. How do you stay up-to-date on the latest advancements and technologies related to chute systems?

To keep abreast of industry advancements, I would:

- Attend industry conferences and workshops to learn about new technologies

- Read technical journals and articles on chute design and optimization

- Network with other Chute Tenders and industry professionals to exchange knowledge

- Participate in continuous improvement programs within the company to explore innovative solutions

8. Describe a situation where you successfully resolved a complex issue related to chute performance?

In a previous role, I encountered a persistent chute blockage that caused significant production delays. I analyzed the material flow patterns, chute design, and operating parameters. I identified a misalignment in the chute supports that caused material to accumulate and block the flow. I adjusted the supports, ensuring proper alignment, and the chute blockage issue was resolved, leading to improved material flow and reduced downtime.

9. How would you prioritize your tasks in a fast-paced manufacturing environment where multiple chute systems require attention?

In a fast-paced environment, I would:

- Identify and address critical issues that could impact production or safety

- Use a system to track the status and priority of different chute maintenance tasks

- Plan and schedule maintenance activities to minimize downtime and optimize resource allocation

- Delegate tasks to other team members when necessary to ensure efficient task completion

10. How would you handle a situation where you disagree with a supervisor’s decision regarding chute maintenance or operations?

If I disagree with a supervisor’s decision, I would:

- Respectfully express my concerns, providing technical or operational reasons for my disagreement

- Present alternative solutions or suggestions, backed by data or experience

- Seek support from other team members or experts to provide additional perspectives

- Be willing to compromise and find a mutually acceptable solution

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chute Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chute Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chute Tenders are responsible for managing the flow of materials in a chute or series of chutes at industrial facilities such as mines or quarries.

1. Operating and Maintaining Equipment

They operate and maintain a variety of equipment, including conveyors, crushers, screens, and other machinery used in the material handling process.

- Monitor equipment for proper operation and make adjustments as needed.

- Identify and troubleshoot equipment malfunctions, and perform basic repairs.

2. Monitoring Material Flow

Chute Tenders monitor the flow of materials through the chutes and ensure that it is consistent and meets production goals.

- Observe the material flow visually or with the help of sensors and instruments.

- Adjust the speed of conveyors or gates to control the flow rate.

3. Ensuring Safety

They take measures to ensure that the material handling process is carried out safely.

- Follow safety protocols and use personal protective equipment.

- Identify and mitigate potential hazards, such as spills or equipment failures.

4. Keeping Work Area Clean

Chute Tenders maintain a clean and organized work area.

- Clean up spills and debris around the chutes.

- Lubricate and inspect equipment regularly.

Interview Tips

Preparing thoroughly for an interview is key to increasing your chances of success. Here are some tips to help you ace your Chute Tender interview:

1. Research the Company and Role

Before the interview, take the time to learn about the company and the specific role you are applying for.

- Visit the company’s website and read about their mission, values, and operations.

- Review the job description carefully and identify the key responsibilities and qualifications.

2. Practice Answering Common Interview Questions

Prepare thoughtful responses to common interview questions, such as:

- Tell me about yourself.

- Why are you interested in this role?

- What are your strengths and weaknesses?

3. Highlight Your Relevant Experience and Skills

Emphasize your relevant experience and skills during the interview. Use specific examples to demonstrate how you have applied these skills in previous roles.

- For example, if you have experience operating heavy machinery, highlight your ability to operate and maintain different types of equipment.

- If you have experience working in a fast-paced environment, describe how you prioritize tasks and manage your time effectively.

4. Ask Insightful Questions

Asking thoughtful questions not only shows that you are interested in the role, but also helps you gather more information about the company and the position.

- For example, you could ask about the company’s plans for growth or about the specific challenges of the role.

- Prepare some questions in advance, but also be prepared to ask follow-up questions based on the interviewer’s responses.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chute Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!