Feeling lost in a sea of interview questions? Landed that dream interview for Roller but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Roller interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

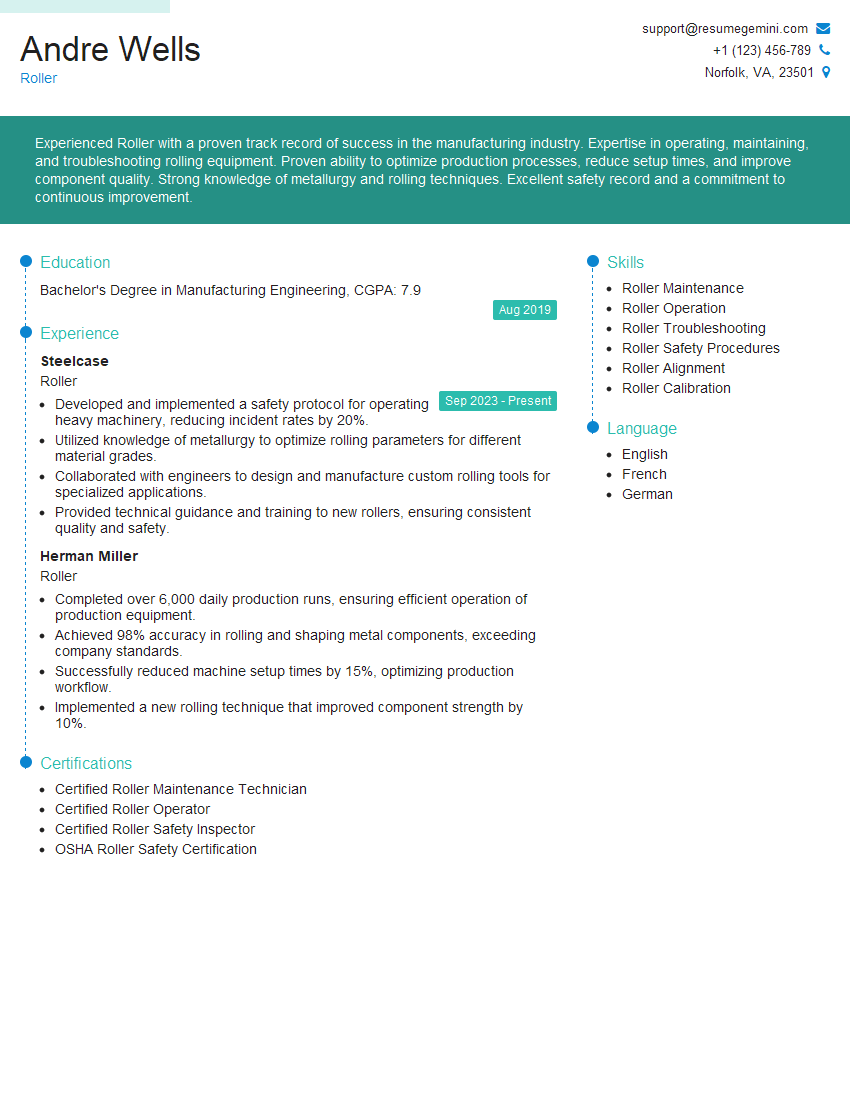

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roller

1. What are the different types of rolling processes used in the manufacturing of steel?

There are several types of rolling processes used in the manufacturing of steel, each with its own advantages and applications. Some of the most common types include:

- Hot rolling: This process involves rolling steel at high temperatures, typically above 925°C (1700°F). Hot rolling is used to produce a wide range of steel products, including bars, rods, sheets, and plates.

- Cold rolling: This process involves rolling steel at room temperature or slightly elevated temperatures. Cold rolling is used to produce steel with a smooth, shiny surface and precise dimensions. Cold-rolled steel is often used in applications where strength and accuracy are important, such as in automotive parts and appliances.

- Shape rolling: This process involves rolling steel through a series of shaped rolls to produce a specific cross-section. Shape rolling is used to produce a wide range of products, including beams, channels, angles, and rails.

- Ring rolling: This process involves rolling a steel ring over a mandrel to increase its diameter. Ring rolling is used to produce a variety of products, including bearings, gears, and wheels.

- Roll forming: This process involves passing steel through a series of rollers to form a specific shape. Roll forming is used to produce a wide range of products, including siding, roofing, and gutters.

2. What are the advantages and disadvantages of hot rolling and cold rolling?

Advantages of hot rolling

- Higher production rates

- Lower energy consumption

- Improved strength and toughness

Disadvantages of hot rolling

- Rougher surface finish

- Less precise dimensions

- Higher risk of cracking

Advantages of cold rolling

- Smoother surface finish

- More precise dimensions

- Higher strength and hardness

Disadvantages of cold rolling

- Lower production rates

- Higher energy consumption

- Increased risk of work hardening and embrittlement

3. What are the different types of steel mill equipment used in the rolling process?

There are a variety of steel mill equipment used in the rolling process, including:

- Rolling mills: Rolling mills are the machines that actually roll the steel. There are many different types of rolling mills, each designed for a specific purpose.

- Furnaces: Furnaces are used to heat the steel before it is rolled. This helps to make the steel more malleable and easier to roll.

- Cooling beds: Cooling beds are used to cool the steel after it has been rolled. This helps to prevent the steel from becoming too brittle.

- Pickling lines: Pickling lines are used to remove scale and other impurities from the surface of the steel. This helps to improve the quality of the finished product.

- Coating lines: Coating lines are used to apply a protective coating to the surface of the steel. This helps to prevent the steel from rusting and corroding.

4. What are the key factors that affect the quality of the rolled steel product?

The quality of the rolled steel product is affected by a number of factors, including:

- The type of steel used

- The rolling process used

- The equipment used in the rolling process

- The skill of the operators

- The quality control procedures in place

5. What are the different types of defects that can occur in the rolling process?

There are a number of different types of defects that can occur in the rolling process, including:

- Cracks: Cracks can occur due to a number of factors, including the presence of defects in the steel, improper rolling conditions, or excessive force being applied to the steel.

- Scratches: Scratches can be caused by a number of factors, including dirt or debris on the surface of the steel, improper handling of the steel, or damage to the rolling equipment.

- Dents: Dents can be caused by a number of factors, including improper handling of the steel, damage to the rolling equipment, or the presence of foreign objects in the rolling process.

- Edge tears: Edge tears can occur due to a number of factors, including improper rolling conditions, the presence of defects in the steel, or excessive force being applied to the steel.

- Roll marks: Roll marks are impressions left on the surface of the steel by the rolling equipment. Roll marks can be caused by a number of factors, including improper rolling conditions, damage to the rolling equipment, or the presence of dirt or debris on the surface of the steel.

6. What are the different ways to prevent defects from occurring in the rolling process?

There are a number of different ways to prevent defects from occurring in the rolling process, including:

- Using high-quality steel

- Using proper rolling conditions

- Using well-maintained equipment

- Training operators properly

- Implementing quality control procedures

7. What are the different types of tests that can be performed to ensure the quality of the rolled steel product?

There are a number of different types of tests that can be performed to ensure the quality of the rolled steel product, including:

- Tensile tests: Tensile tests measure the strength and ductility of the steel.

- Hardness tests: Hardness tests measure the resistance of the steel to penetration.

- Impact tests: Impact tests measure the toughness of the steel.

- Fatigue tests: Fatigue tests measure the resistance of the steel to repeated loading.

- Corrosion tests: Corrosion tests measure the resistance of the steel to rust and corrosion.

8. What are the different applications of rolled steel?

Rolled steel is used in a wide variety of applications, including:

- Construction

- Automotive

- Appliances

- Industrial machinery

- Transportation

9. What are the latest trends in the rolling industry?

Some of the latest trends in the rolling industry include:

- The use of new technologies to improve the quality and efficiency of the rolling process

- The development of new products and applications for rolled steel

- The increasing use of recycled steel in the rolling process

10. What are the challenges facing the rolling industry?

Some of the challenges facing the rolling industry include:

- The increasing cost of raw materials

- The competition from other materials, such as aluminum and plastics

- The need to meet increasingly stringent environmental regulations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Roller plays a crucial role in various industries, primarily focusing on the operation of heavy rollers and machinery. Their key responsibilities encompass:

1. Equipment Operation

Skilled in operating heavy rollers, compactors, and other related equipment to smoothen and compact surfaces in construction projects.

2. Site Preparation

Responsible for preparing construction sites by grading, leveling, and compacting the ground to ensure a solid foundation for further construction.

3. Asphalt Paving

Efficiently spread and compact asphalt mixtures to create smooth and durable road surfaces, parking lots, and other paved areas.

4. Earthwork and Excavation

Involved in earthwork operations, including excavation, grading, and backfilling, to prepare the ground for various construction projects.

5. Equipment Maintenance

Perform basic maintenance and repairs on rollers and other equipment, ensuring they operate efficiently and safely.

Interview Tips

To excel in your Roller interview, consider these preparation tips and hacks:

1. Research the Company and Role

Thoroughly research the construction company and the specific Roller position to understand their industry standing, project history, and job requirements.

2. Highlight Relevant Experience

Emphasize your hands-on experience in operating heavy rollers, site preparation, asphalt paving, and earthwork. Quantify your accomplishments with specific metrics to demonstrate your impact.

3. Showcase Safety Awareness

Safety is paramount in construction. Highlight your commitment to following safety protocols, wearing appropriate gear, and maintaining a clean and organized worksite.

4. Demonstrate Physical Fitness

The role of a Roller requires physical strength and stamina. Prepare to discuss your physical abilities and provide examples of how you maintain your fitness.

5. Practice Common Interview Questions

Anticipate common interview questions and prepare your responses. Practice STAR (Situation, Task, Action, Result) method to effectively articulate your experiences and skills.

6. Prepare Industry-Specific Questions

Research the construction industry and prepare industry-specific questions to demonstrate your knowledge and enthusiasm for the field.

7. Dress Professionally

First impressions matter. Dress professionally and arrive on time for your interview to show respect and make a positive impact.

8. Be Enthusiastic and Confident

Convey your passion for the Roller profession and confidence in your abilities. Enthusiasm and a positive attitude can greatly influence the interviewer’s perception.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Roller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!