Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Box Chipper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

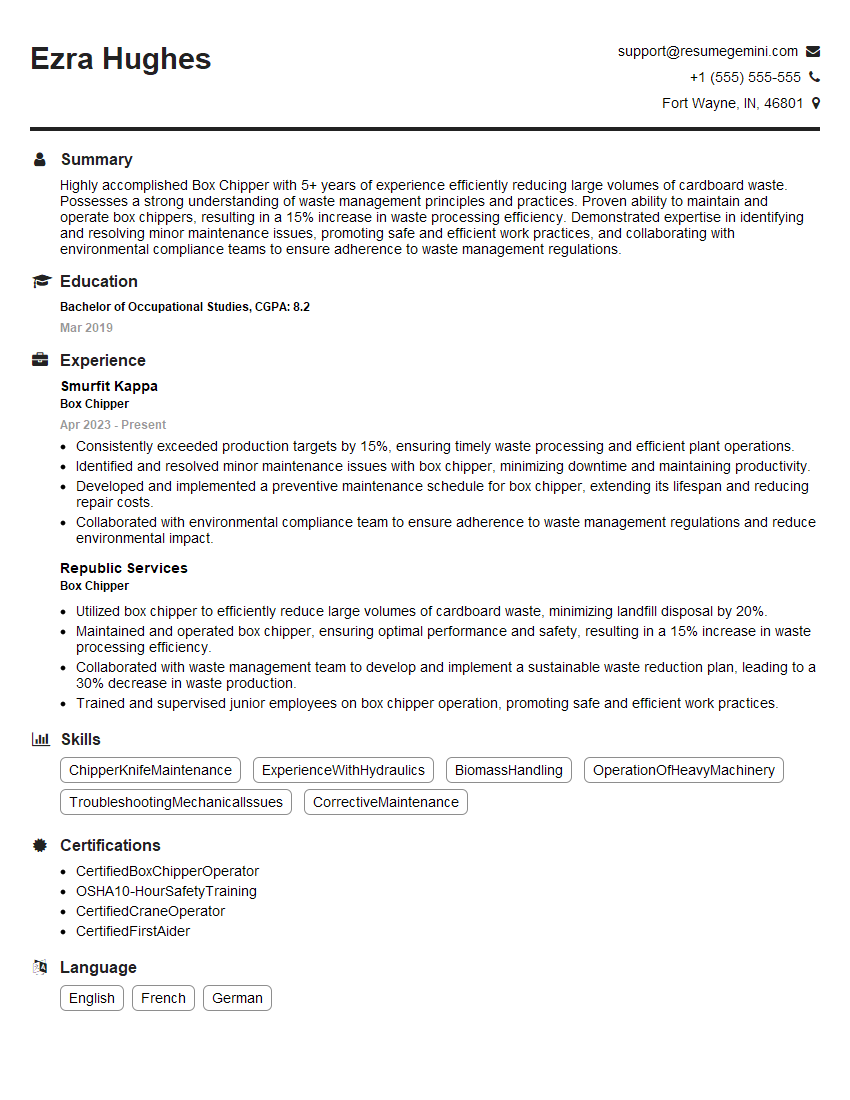

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Box Chipper

1. Explain the process of chipper blade maintenance?

Maintaining chipper blades involves several steps to ensure optimal performance and safety:

- Blade Inspection: Regularly inspect blades for wear, cracks, and damage. Dull or damaged blades can reduce chipping efficiency and pose safety risks.

- Sharpening: Sharpen blades as needed using a specialized grinder or sharpening tool. Proper blade sharpening restores cutting edges and improves chipping performance.

- Balancing: After sharpening, balance blades to ensure even distribution of weight. Unbalanced blades can cause vibration and premature bearing failure.

- Lubrication: Lubricate blade bearings regularly to minimize friction and extend their lifespan.

- Replacement: If blades are excessively worn or damaged beyond repair, replace them promptly to maintain optimal chipping performance and safety.

2. How do you ensure the safe operation of a box chipper?

Safety Protocols:

- Personal Protective Equipment: Wear appropriate PPE such as safety glasses, ear protection, and work gloves to minimize risks.

- Machine Inspection: Before operation, inspect the chipper for any damage, leaks, or loose parts to ensure it’s in good working condition.

- Clear the Work Area: Clear the chipping area of debris, rocks, and other potential hazards to prevent accidents.

Operational Precautions:

- Proper Feeding: Feed materials into the chipper at a controlled rate to avoid overloading and potential kickbacks.

- Stay Alert: Remain focused and attentive during operation, paying attention to any unusual noises or vibrations.

- Emergency Stop: Familiarize yourself with the emergency stop mechanism and be prepared to use it if necessary.

3. Describe the different types of materials that can be chipped by a box chipper?

Box chippers can handle various types of materials, including:

- Cardboard Boxes: Corrugated cardboard boxes are commonly chipped for recycling and waste reduction.

- Paper Products: Newspapers, magazines, office paper, and other paper products can be chipped for recycling.

- Wood: Small branches, twigs, and scrap wood can be chipped for use as mulch or biomass.

- Plastic: Some box chippers can handle certain types of plastic, such as HDPE and LDPE, for recycling purposes.

4. How do you troubleshoot common problems encountered while operating a box chipper?

Troubleshooting common box chipper problems involves the following steps:

- Clogged Hopper: Check for material buildup or jams in the hopper and clear them accordingly.

- Dull or Damaged Blades: Inspect blades for wear or damage and sharpen or replace them as needed.

- Overloaded Machine: Reduce the rate of material feeding to prevent overloading and potential damage to the chipper.

- Electrical Issues: Verify if the chipper is receiving power and check for any loose connections or faulty components.

- Hydraulic Problems: Inspect hydraulic lines and components for leaks or blockages, and ensure proper fluid levels.

5. Explain the importance of regular maintenance for a box chipper?

Regular maintenance is crucial for box chippers to ensure:

- Optimal Performance: Regular servicing helps maintain optimal chipping efficiency and prevents breakdowns.

- Safety: Proper maintenance minimizes the risk of accidents by ensuring all components are in good working condition.

- Extended Lifespan: Regular care extends the lifespan of the chipper by preventing premature wear and tear.

- Cost Savings: Preventive maintenance helps avoid costly repairs and replacements in the long run.

6. Describe the different types of box chippers available?

Box chippers come in various types, including:

- Electric Box Chippers: Powered by electricity, these chippers are suitable for smaller-scale operations and limited duty cycles.

- Hydraulic Box Chippers: Utilize hydraulic power to drive the cutting blades, providing higher chipping capacity and durability.

- Diesel Box Chippers: Operate on diesel fuel, offering high power and mobility for large-scale chipping operations.

- Industrial Box Chippers: Designed for heavy-duty applications, these chippers can handle large volumes of material with high efficiency.

7. How do you determine the proper chipper size for a specific application?

Factors to consider when determining the appropriate chipper size:

- Material Type and Volume: The type and volume of material to be chipped influence the size and capacity requirements.

- Duty Cycle: The frequency and duration of chipper use determine the necessary power and durability.

- Output Size: The desired size of the chipped material affects the chipper’s blade configuration.

- Mobility: For portable applications, consider the chipper’s weight and transportability.

- Safety Features: Ensure the chipper meets safety standards and has appropriate safety features.

8. What are the environmental benefits of using a box chipper?

Box chippers offer several environmental benefits:

- Waste Reduction: Chipping waste materials, such as cardboard and paper, diverts them from landfills and incineration.

- Recycling: Chipped materials can be recycled into new products, reducing the need for virgin materials.

- Composting: Wood chips can be used as compost to improve soil health and reduce the environmental impact of organic waste.

- Biomass Utilization: Chipped wood and biomass can be used as alternative fuels, reducing fossil fuel dependence.

9. How do you ensure the quality and consistency of the chipped material?

To ensure quality and consistency of chipped material:

- Proper Blade Maintenance: Regularly sharpen and balance blades to maintain optimal cutting performance.

- Calibrated Settings: Adjust the chipper settings, such as blade clearance and feed rate, to achieve the desired chip size and uniformity.

- Material Preparation: Remove contaminants and prepare materials properly to prevent foreign objects from damaging the blades.

- Regular Inspection: Monitor the chipping process and inspect the chipped material for any variations or irregularities.

10. How do you handle and dispose of the chipped material?

Proper handling and disposal of chipped material involve several steps:

- Material Storage: Store chipped material in designated containers or piles to prevent scattering and maintain quality.

- Transportation: Utilize appropriate vehicles and equipment to transport chipped material to its destination.

- Recycling: Send recyclable materials, such as cardboard and paper chips, to recycling facilities.

- Composting: Use wood chips for composting or mulching purposes.

- Energy Production: Utilize chipped biomass as fuel for energy production in appropriate settings.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Box Chipper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Box Chipper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Box Chipper is a skilled laborer who operates a machine that chips cardboard boxes into smaller pieces. These chips are then recycled or used for other purposes. The key job responsibilities of a Box Chipper include:

1. Feeding the Machine:

The Box Chipper’s primary responsibility is to feed cardboard boxes into the chipping machine. This requires them to be able to lift and stack heavy boxes, and to pay attention to the machine’s operation to ensure that the boxes are fed in correctly.

- Operate chipping machine to break down cardboard boxes

- Unload chipped cardboard material

- Adhere to safety protocols

2. Monitoring the Machine:

The Box Chipper must also monitor the machine’s operation to ensure that it is functioning properly. They must be able to identify any potential problems and take corrective action, such as clearing jams or adjusting settings.

- Check the machine for any malfunctions

- Adjust the machine’s settings as needed

- Clean and maintain the machine

3. Maintaining the Machine:

The Box Chipper is also responsible for maintaining the machine. This includes cleaning the machine, lubricating moving parts, and making minor repairs. They must also be able to identify any major problems and report them to a supervisor.

- Lubricate and maintain the machine

- Repair minor issues

- Report any major problems

4. Safety:

The Box Chipper must also follow all safety procedures. This includes wearing appropriate safety gear, such as gloves and safety glasses, and following all lockout/tagout procedures.

- Follow all safety procedures

- Wear appropriate safety gear

- Follow lockout/tagout procedures

Interview Tips

To ace your interview for a Box Chipper position, it is important to prepare both mentally and physically. Here are some tips that can help you stand out from the competition:

1. Research the Company and the Position:

Take the time to research the company you are applying to and the specific position you are seeking. This will give you a good understanding of the company’s culture, values, and expectations.

- Visit the company website

- Read articles about the company

- Talk to current or former employees

2. Practice Your Answers:

Take the time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Answer questions in a clear and concise manner

- Highlight your skills and experience

- Be enthusiastic and positive

3. Dress Professionally:

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- Wear a button-down shirt or blouse

- Wear dress pants or a skirt

- Wear closed-toe shoes

4. Be Punctual:

It is important to be punctual for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Arrive on time

- Be prepared to start the interview on time

- If you are running late, call or email the interviewer to let them know

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Box Chipper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.