Are you gearing up for an interview for a Paper Wood Cutter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Paper Wood Cutter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

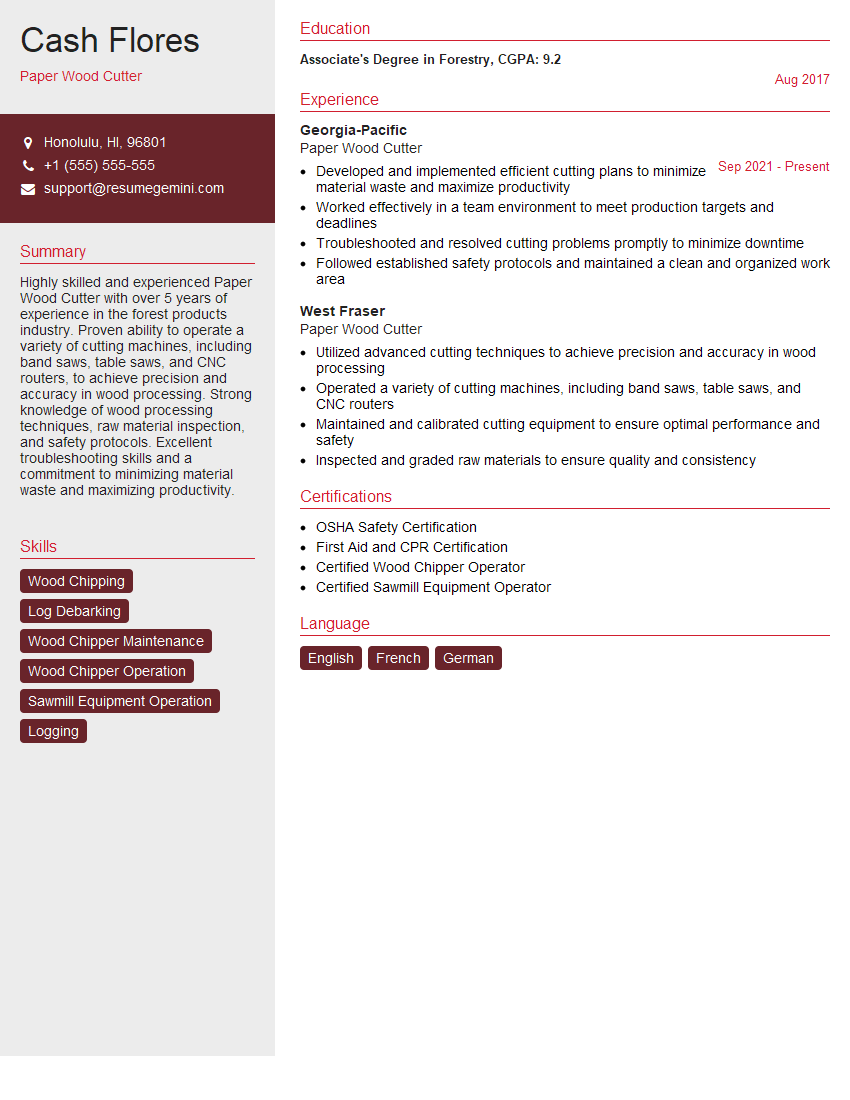

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paper Wood Cutter

1. Explain the process of cutting and refining wood pulp for paper production.

The process of cutting and refining wood pulp for paper production involves several stages:

- Tree Felling and Debarking: Trees are harvested and stripped of their bark, which can be used for various purposes.

- Wood Chipping: The debarked logs are chipped into small pieces using a chipper, which produces wood chips of uniform size.

- Digesting: The wood chips are cooked in a digester with chemicals, such as sodium hydroxide or kraft liquor, to dissolve lignin, the glue-like substance that binds wood fibers together.

- Pulp Washing: The digested pulp is washed thoroughly to remove chemicals and impurities, leaving behind cellulose fibers.

- Screening and Bleaching: The washed pulp is screened to remove any remaining contaminants and then bleached using chemicals like chlorine or hydrogen peroxide to brighten it.

2. Describe the different types of papermaking machines and their respective advantages and disadvantages.

Fourdrinier Machine

- Advantages: High production rate, produces a wide variety of paper grades, versatile in terms of fiber types.

- Disadvantages: Can be complex and expensive to operate.

Cylinder Mold Machine

- Advantages: Produces high-quality paper with a bulkier feel, suitable for specialty papers.

- Disadvantages: Lower production rate compared to Fourdrinier machines.

Twin-Wire Machine

- Advantages: Produces paper with improved formation and strength properties.

- Disadvantages: Can be more expensive than other machine types.

3. Explain the importance of controlling the moisture content in paper production and the methods used to achieve it.

Controlling moisture content in paper production is crucial because it affects the paper’s properties, such as strength, dimensional stability, and printability. To achieve the desired moisture content:

- Pressing: The wet paper web is passed through a series of rollers to remove water.

- Drying: The paper is passed through heated rollers or air dryers to evaporate moisture.

- Conditioning: The dried paper is stored in controlled humidity environments to stabilize its moisture content.

4. Discuss the role of additives in paper production and the different types of additives used.

Additives play a vital role in enhancing the properties and performance of paper. Some common types of additives include:

- Fillers (e.g., calcium carbonate, clay): Improve opacity, brightness, and printability.

- Sizing agents (e.g., starch, rosin): Enhance water resistance and ink absorption properties.

- Strength agents (e.g., polyacrylamide, guar gum): Increase tensile strength, tear strength, and burst strength.

- Optical brighteners: Increase the whiteness and brightness of paper.

5. Describe the different methods used for surface treatment of paper and their respective effects.

Coating

- Applies a thin layer of coating material, such as clay or calcium carbonate, to improve surface smoothness, gloss, and printability.

Calendering

- Passes the paper through a series of rollers to improve surface smoothness, density, and gloss.

Embossing

- Creates a raised or textured pattern on the paper surface for decorative or functional purposes.

6. Explain the principles of paper testing and the different tests conducted to evaluate paper properties.

Paper testing involves various techniques to evaluate its physical and chemical properties. Common tests include:

- Tensile Strength Test: Measures the resistance of paper to breaking under tensile force.

- Tear Strength Test: Assesses the resistance of paper to tearing.

- Burst Strength Test: Evaluates the resistance of paper to bursting under pressure.

- Brightness Test: Measures the whiteness and brightness of paper.

- Opacity Test: Determines the ability of paper to block light.

7. Discuss the environmental considerations in paper production and the measures taken to minimize environmental impact.

Paper production requires responsible environmental stewardship. Measures taken to minimize impact include:

- Sustainable Forestry: Sourcing wood from sustainably managed forests.

- Chemical Recovery: Recovering and reusing chemicals used in pulping processes.

- Water Treatment: Treating wastewater to reduce pollution.

- Energy Efficiency: Implementing energy-efficient technologies and practices.

- Recycling and Waste Reduction: Promoting paper recycling and reducing waste generation.

8. Explain the role of automation in modern papermaking and its impact on productivity and efficiency.

Automation spielt eine entscheidende Rolle in der modernen Papierherstellung:

- Verminderte Ausfallzeiten und erhöhte Produktionseffizienz.

- Verbesserte Qualität und Konsistenz des Papiers.

- Geringerer Bedarf an Arbeitskräften und geringere Betriebskosten.

- Bessere Überwachung und Steuerung des Produktionsprozesses.

9. Describe the different types of paper grades and their specific applications.

Druck- und Schreibpapiere

- Für Drucker, Kopierer und Schreibzwecke.

Verpackungspapiere

- Für Verpackungszwecke, wie z. B. Kartons, Säcke und Wellpappe.

Spezialpapiere

- Für spezifische Anwendungen, z. B. Filterpapiere, Etikettenpapiere, Fotopapiere.

10. Discuss the latest advancements and trends in paper production technology.

- Neue Faserquellen und nachhaltige Rohstoffe.

- Erweiterter Einsatz von Automatisierung und Digitalisierung.

- Entwicklung von funktionellen Papieren mit speziellen Eigenschaften.

- Verbesserte Umweltfreundlichkeit und Kreislaufwirtschaft.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paper Wood Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paper Wood Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paper Wood Cutters are responsible for operating and maintaining paper cutting machinery, ensuring the efficient and precise cutting of paper products. Their responsibilities encompass a range of tasks, including:

1. Machine Setup and Operation

Setting up and operating paper cutting machines of various types, including guillotine cutters, rotary cutters, and die cutters

- Calibrating and adjusting machines to meet specific cutting requirements

- Loading and unloading paper rolls or stacks onto the machine

- Monitoring machine operation and making necessary adjustments to ensure smooth and efficient cutting

2. Cutting and Finishing Operations

Cutting paper to precise dimensions, according to specifications

- Using a variety of cutting techniques, such as straight cutting, angled cutting, and shape cutting

- Inspecting cut paper for accuracy and quality

- Performing finishing operations, such as creasing, scoring, and perforating

3. Machine Maintenance and Repair

Performing preventive maintenance on paper cutting machines, including lubrication, cleaning, and minor repairs

- Identifying and troubleshooting machine malfunctions

- Making necessary adjustments or repairs to ensure optimal machine performance

4. Safety and Compliance

Adhering to established safety protocols and procedures when operating paper cutting machines

- Wearing appropriate safety gear, such as gloves, eye protection, and hearing protection

- Ensuring that the work area is clean and organized

- Following all applicable regulations and standards for paper cutting operations

Interview Tips

To effectively prepare for an interview for a Paper Wood Cutter position, candidates should focus on demonstrating their technical skills, attention to detail, and commitment to safety. Here are some specific tips:

1. Research the Company and Position

Thoroughly research the company and the specific Paper Wood Cutter position. Understand the company’s products, services, and industry experience. Review the job description carefully to identify the key responsibilities and qualifications required for the role.

2. Practice Answering Common Interview Questions

Prepare for common interview questions related to your skills and experience as a Paper Wood Cutter. Consider the following examples and prepare thoughtful responses:

- Tell us about your experience operating paper cutting machines.

- Describe a time when you had to troubleshoot a machine malfunction.

- How do you ensure the accuracy and quality of your cuts?

- What safety measures do you prioritize when operating paper cutting machinery?

- How do you stay up-to-date on the latest paper cutting techniques and technologies?

3. Highlight Your Technical Skills and Experience

Emphasize your technical skills and experience in operating paper cutting machines. Provide specific examples of your proficiency in machine setup, cutting operations, and maintenance tasks. Quantify your accomplishments whenever possible to demonstrate your impact on productivity and efficiency.

4. Demonstrate Attention to Detail

Highlight your attention to detail and precision in your work. Explain how you carefully inspect cut paper for accuracy and quality. Share examples of how your meticulous approach has contributed to the success of your previous projects.

5. Emphasize Your Commitment to Safety

Stress your commitment to safety in the workplace. Describe your adherence to established safety protocols and your understanding of the importance of proper machine operation and maintenance. Explain how you prioritize the well-being of yourself and your colleagues.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Paper Wood Cutter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.