Are you gearing up for a career in Stroke Delimber Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Stroke Delimber Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

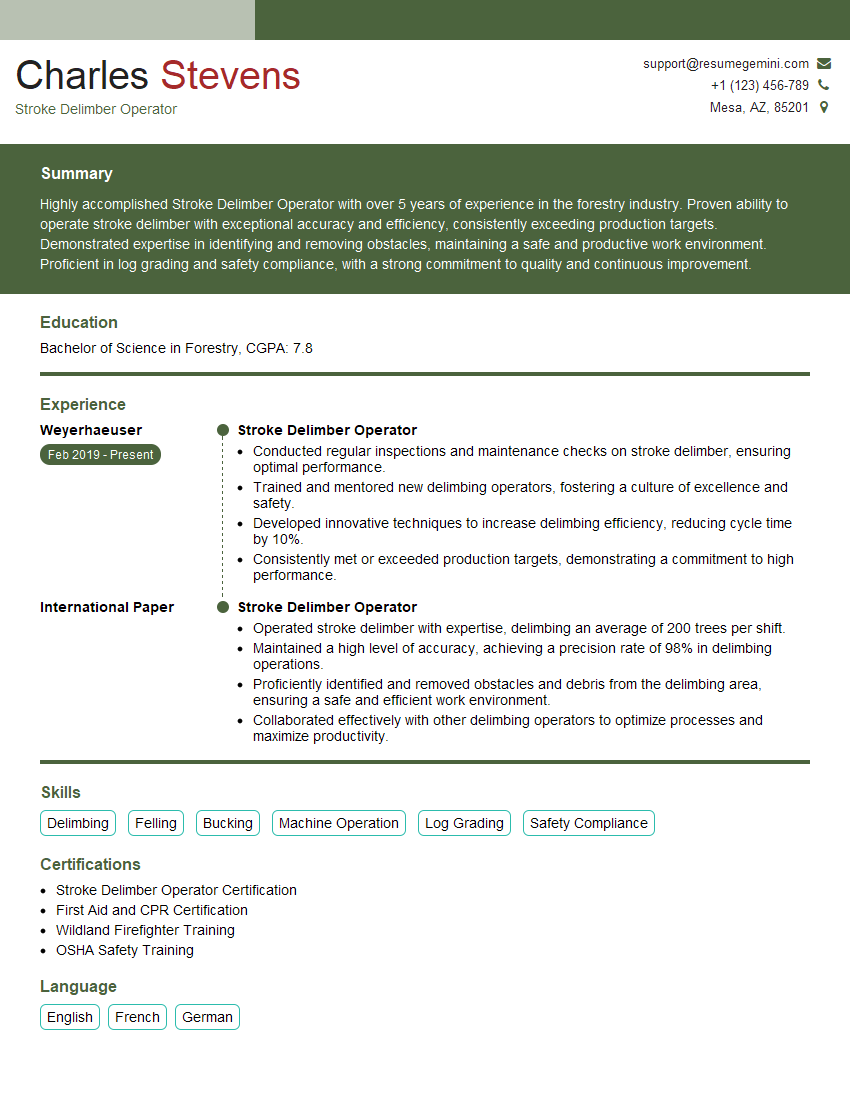

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stroke Delimber Operator

1. Describe the critical components of a stroke delimber and their functions.

The crucial components of a stroke delimber and their functions include:

- Stroke engine: Powers the hydraulic system that operates the delimbing knives.

- Hydraulic system: Transmits power from the stroke engine to the delimbing knives.

- Delimiting knives: Cut the limbs from the tree.

- Feed rolls: Pull the tree through the delimber.

2. What are the different types of stroke delimbers?

Hydraulic stroke delimbers

- Use hydraulic fluid to power the delimbing knives.

Pneumatic stroke delimbers

- Use air to power the delimbing knives.

- Often smaller and more portable than hydraulic models.

Mechanical stroke delimbers

- Use a mechanical linkage to power the delimbing knives.

- Simpler in design than hydraulic and pneumatic models.

3. What are the key factors to consider when choosing a stroke delimber?

When selecting a stroke delimber, the following factors should be considered:

- Type of delimber: Hydraulic, pneumatic, or mechanical.

- Size of the delimber: Capacity to handle the size of trees being processed.

- Power source: Availability of hydraulic, pneumatic, or mechanical power.

- Portability: How easily the delimber can be moved between locations.

- Cost: Capital and operating costs of the delimber.

4. What are the proper safety procedures when working with a stroke delimber?

Safety procedures for working with a stroke delimber include:

- Wear appropriate safety gear: Hard hat, safety glasses, gloves, and protective clothing.

- Inspect the delimber before each use: Check for any damage or loose components.

- Keep the area around the delimber clear: Remove any debris or obstacles.

- Be aware of your surroundings: Pay attention to moving equipment and personnel.

- Never operate the delimber while under the influence of drugs or alcohol.

5. What are the most common maintenance tasks required for a stroke delimber?

Regular maintenance tasks for a stroke delimber include:

- Check the hydraulic fluid level and condition: Add or replace fluid as needed.

- Check the air filter: Clean or replace the air filter regularly.

- Lubricate all moving parts: Use a high-quality lubricant to reduce friction and wear.

- Inspect the delimbing knives for damage: Sharpen or replace knives as needed.

- Tighten any loose bolts or nuts: Ensure all components are securely fastened.

6. How do you troubleshoot a stroke delimber that is not feeding properly?

Troubleshooting steps for a stroke delimber that is not feeding properly include:

- Check the hydraulic fluid level and condition: Low fluid levels or contaminated fluid can cause poor performance.

- Inspect the hydraulic hoses and fittings: Look for any leaks or damage.

- Check the feed rolls: Ensure the feed rolls are engaged and turning properly.

- Inspect the delimbing knives: Dull or damaged knives can reduce cutting efficiency.

- Check the power source: Ensure the delimber is receiving adequate power.

7. What are the different types of stroke delimbing patterns?

Common stroke delimbing patterns include:

- Full tree delimbing: The entire tree is passed through the delimber to remove all branches.

- Top delimbing: Only the upper portion of the tree is passed through the delimber to remove branches.

- Butt delimbing: Only the lower portion of the tree is passed through the delimber to remove branches.

- Selective delimbing: Only specific branches are targeted for removal.

8. What is the purpose of a stroke delimber in the logging process?

A stroke delimber serves the following purposes in the logging process:

- Removes branches from trees: This facilitates the handling and processing of logs.

- Improves log quality: Delimbing removes defects and improves the overall value of the logs.

- Increases productivity: Stroke delimbers can process logs faster than manual delimbing methods.

- Enhances safety: Delimbing reduces the risk of accidents associated with manual limbing.

9. What are the challenges associated with operating a stroke delimber?

Challenges commonly faced when operating a stroke delimber include:

- Equipment maintenance: Stroke delimbers require regular maintenance to ensure optimal performance.

- Environmental conditions: Cold temperatures, rain, and snow can impact delimber operation.

- Tree size and species: Different tree sizes and species can affect the efficiency of delimbing.

- Operator skill: Proper operation is necessary to achieve optimal delimbing results.

10. Describe your experience in operating and maintaining stroke delimbers.

- Highlight your involvement in all aspects of stroke delimber operations, including setup, operation, and maintenance.

- Mention any specific challenges you have overcome and the solutions you implemented.

- Quantify your accomplishments whenever possible, providing specific metrics or results achieved.

- Emphasize your attention to safety and your commitment to following proper procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stroke Delimber Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stroke Delimber Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Stroke Delimber Operator is responsible for operating and maintaining a stroke delimber machine, which is used to remove branches and limbs from harvested trees. The primary goal is to prepare the logs for further processing at a sawmill or other wood processing facility.

1. Operate Stroke Delimber Machine

The central task of the Stroke Delimber Operator is to skillfully operate the stroke delimber machine. This involves:

- Positioning the machine correctly for efficient delimbing of logs.

- Controlling the delimbing head and hydraulic systems to remove branches and limbs.

- Adjusting the delimbing speed and pressure to optimize the process.

- Monitoring the machine’s performance and making adjustments as needed.

2. Inspect and Maintain Equipment

To ensure smooth operations, the operator must regularly inspect and maintain the stroke delimber machine. This includes:

- Checking for any signs of wear or damage to the equipment.

- Lubricating and greasing moving parts to prevent friction and breakdowns.

- Replacing worn or damaged components promptly.

- Keeping the machine clean to prevent debris buildup.

3. Monitor Production and Quality

The Stroke Delimber Operator is responsible for monitoring the production output and quality of the delimbed logs. This involves:

- Ensuring that the desired delimbing specifications are met.

- Inspecting delimbed logs for any missed branches or damage.

- Making adjustments to the delimbing process as needed to improve efficiency and quality.

- Reporting any production or quality issues to supervisors promptly.

4. Safety and Compliance

The operator must adhere to all safety regulations and guidelinesrelated to the operation of the stroke delimber machine. This includes:

- Wearing appropriate personal protective equipment (PPE).

- Following established safety procedures for machine operation.

- Maintaining a clean and organized work area to prevent accidents.

- Reporting any safety concerns or hazards to supervisors immediately.

Interview Tips

To prepare effectively for an interview as a Stroke Delimber Operator, it is crucial to showcase your skills and experience that align with the job requirements. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, values, and the specific responsibilities of the Stroke Delimber Operator role. This demonstrates your interest in the position and the organization.

- Thoroughly review the job description to understand the key tasks and expectations.

- Visit the company website to learn about their history, industry involvement, and any recent news or developments.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job. Use specific examples to demonstrate your abilities:

- Describe your experience operating stroke delimber machines, including the types of machines you have worked with and the specific tasks you performed.

- Share examples of how you have successfully maintained and inspected heavy machinery, highlighting your attention to detail and problem-solving abilities.

3. Showcase Safety Awareness and Compliance

Safety is paramount in this role. Showcase your understanding of safety regulations and your commitment to following established procedures:

- Explain your knowledge of relevant safety guidelines and how you ensure compliance in your work.

- Provide examples of how you have proactively identified and addressed safety hazards in the workplace.

4. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivations. Practice your responses to questions such as:

- “Tell me about your experience operating stroke delimber machines.”

- “Describe a situation where you encountered a problem with the machine and how you resolved it.”

- “How do you prioritize safety and ensure compliance in your work?”

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest in the position and the company. This shows that you are engaged and eager to learn more:

- Inquire about the company’s commitment to safety and environmental practices.

- Ask about opportunities for professional development and advancement within the organization.

- Express your enthusiasm for the role and how your skills and experience can contribute to the team’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Stroke Delimber Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!