Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Buncher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

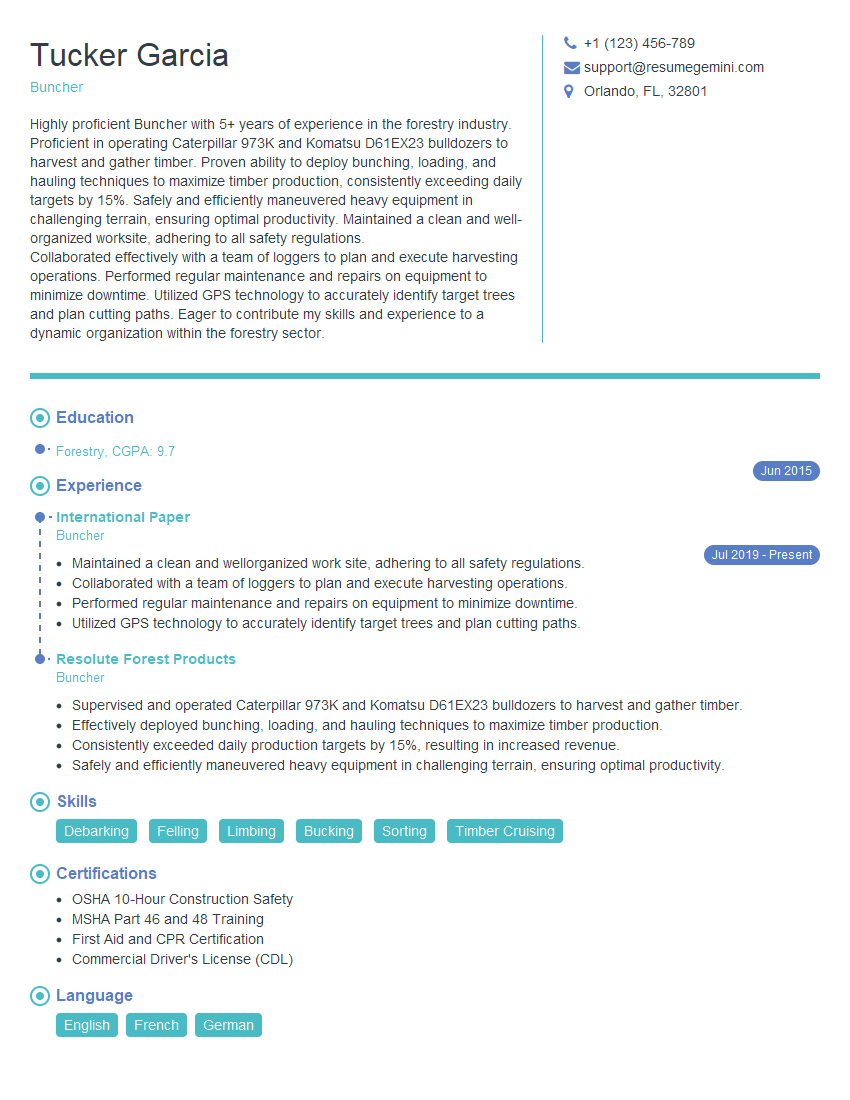

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Buncher

1. What are the different types of bunchers used in logging operations?

- Stationary bunchers: These bunchers are mounted on a fixed base and are used to gather logs from a specific area. They are typically used in conjunction with a skidder to transport the logs to a landing.

- Mobile bunchers: These bunchers are mounted on a wheeled or tracked vehicle and can be moved around the logging site. They are used to gather logs from a wider area and can be used to create multiple bunches of logs.

- Self-propelled bunchers: These bunchers are equipped with their own engine and drivetrain, which allows them to move around the logging site without the need for a separate skidder. They are typically used in large-scale logging operations.

2. What are the main components of a buncher?

The main components of a buncher include:

- Base: The base of the buncher provides stability and support for the machine. It is typically made of steel or other durable materials.

- Boom: The boom is a long, hydraulically powered arm that is used to lift and move logs. It is typically made of steel or aluminum.

- Grapple: The grapple is a hydraulically powered attachment that is used to grip and hold logs. It is typically made of steel or other durable materials.

- Cab: The cab is the enclosed area where the operator of the buncher sits. It is typically made of steel or aluminum and is equipped with controls for operating the machine.

- Engine: The engine provides power for the hydraulic system that powers the boom, grapple, and other components of the buncher. It is typically a diesel engine.

3. What are the safety considerations when operating a buncher?

- Always wear proper personal protective equipment (PPE), including a hard hat, safety glasses, and gloves.

- Be aware of your surroundings and the location of other workers.

- Do not operate the buncher if you are tired or under the influence of alcohol or drugs.

- Inspect the buncher before each use and make sure that all components are in good working order.

- Follow all manufacturer’s instructions for operating the buncher.

4. What are the most common maintenance tasks that need to be performed on a buncher?

- Checking and adjusting fluid levels

- Replacing filters

- Greasing moving parts

- Inspecting and repairing hydraulic hoses and fittings

- Checking and adjusting the grapple

5. What are the different types of terrain that bunchers can operate on?

- Flat ground: Bunchers can operate on flat ground with ease. They are typically used in areas where the terrain is relatively level and there are few obstacles.

- Slopes: Bunchers can also operate on slopes, but they must be careful not to tip over. The angle of the slope will determine the maximum load that the buncher can carry.

- Wet ground: Bunchers can operate on wet ground, but they must be careful not to get stuck. The type of soil will determine how well the buncher can operate on wet ground.

- Snow: Bunchers can operate in snow, but they must be equipped with snow tracks or chains. The depth of the snow will determine the maximum load that the buncher can carry.

6. What are the different types of logs that bunchers can handle?

- Softwood logs: Softwood logs are typically made from pine, fir, or spruce trees. They are relatively light and easy to handle.

- Hardwood logs: Hardwood logs are typically made from oak, maple, or birch trees. They are heavier and more difficult to handle than softwood logs.

- Mixed logs: Mixed logs are a combination of softwood and hardwood logs. They can be more difficult to handle than either softwood or hardwood logs alone.

7. What are the different methods of bunching logs?

- Single-grip bunching: In single-grip bunching, the grapple is used to grip and lift a single log at a time. This method is typically used for small logs or logs that are difficult to handle.

- Multi-grip bunching: In multi-grip bunching, the grapple is used to grip and lift multiple logs at a time. This method is typically used for large logs or logs that are easy to handle.

- Combination bunching: In combination bunching, a combination of single-grip and multi-grip bunching is used. This method is typically used for logs of varying sizes and weights.

8. What are the advantages of using a buncher?

- Increased productivity: Bunchers can significantly increase productivity by gathering logs more efficiently than manual labor.

- Reduced labor costs: Bunchers can reduce labor costs by eliminating the need for multiple workers to manually gather logs.

- Improved safety: Bunchers can help to improve safety by reducing the risk of injuries to workers.

- Reduced environmental impact: Bunchers can help to reduce the environmental impact of logging operations by minimizing soil disturbance.

9. What are the disadvantages of using a buncher?

- High initial cost: Bunchers can be expensive to purchase and maintain.

- Requires skilled operators: Bunchers require skilled operators to operate safely and efficiently.

- Limited mobility: Bunchers are not as mobile as some other logging equipment, which can limit their use in some areas.

10. What are the future trends in buncher technology?

- Increased automation: Bunchers are becoming increasingly automated, which is reducing the need for skilled operators.

- Improved efficiency: Bunchers are becoming more efficient, which is increasing productivity and reducing costs.

- Reduced environmental impact: Bunchers are becoming more environmentally friendly, which is reducing the impact of logging operations on the environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Buncher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Buncher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Buncher is responsible for a variety of tasks in a manufacturing or production environment. Their primary role is to assemble or combine individual components or parts into finished products or subassemblies. They work with various tools and equipment, such as hand tools, power tools, and machinery, to assemble products according to specifications and quality standards.

1. Component Preparation

Preparing components for assembly, such as cleaning, sorting, and inspecting them to ensure they meet specifications.

- Inspecting components for defects, damage, or any other issues that may impact the assembly process.

- Sorting components based on size, shape, or other characteristics to facilitate efficient assembly.

2. Assembly Process

Carrying out the assembly process according to established procedures and work instructions.

- Using hand tools, power tools, or machinery to join components together, such as using screwdrivers, wrenches, or welding equipment.

- Following detailed instructions and blueprints to ensure accurate assembly and compliance with quality standards.

3. Quality Control

Performing quality checks on assembled products to ensure they meet specifications.

- Inspecting finished products for defects, errors, or any other issues that may compromise their functionality or safety.

- Using measuring tools, gauges, or other equipment to verify dimensions, tolerances, and other critical parameters.

4. Process Improvement

Identifying areas for improvement in the assembly process and suggesting solutions.

- Observing and analyzing the assembly process to identify bottlenecks, inefficiencies, or areas where quality can be enhanced.

- Proposing modifications to the process, equipment, or work instructions to improve efficiency and reduce errors.

Interview Tips

Preparing for an interview for the position of Buncher requires a combination of research, practice, and confidence. Here are some tips to help you ace the interview.

1. Research the Company and the Role

Before the interview, take the time to learn about the company where you are applying for the position of Buncher. Understand their industry, products or services, company culture, and the specific requirements of the role.

- Review the company’s website, social media pages, and any available press releases or news articles.

- Pay attention to the company’s mission, values, and any sustainability or social responsibility initiatives they may have.

2. Practice Your Answers to Common Interview Questions

Anticipate the common interview questions that you may be asked and prepare your answers in advance. This will help you feel more confident and articulate during the interview.

- Prepare answers to questions about your experience in assembly or manufacturing, your quality control skills, and your ability to work in a team environment.

- Consider how your skills and experience align with the job requirements and highlight these in your answers.

3. Highlight Your Attention to Detail and Quality

Employers seek candidates who are detail-oriented and committed to producing high-quality work. Emphasize your meticulous nature and your ability to work accurately and efficiently.

- Provide examples of your attention to detail, such as checking for errors in components or ensuring precise measurements in assembly.

- Explain how you maintain a clean and organized work area and follow established quality control procedures.

4. Showcase Your Problem-Solving Abilities

In manufacturing, problem-solving skills are crucial. Demonstrate your ability to identify and resolve issues that may arise during the assembly process.

- Describe situations where you encountered problems and explain how you analyzed the issue and took steps to solve it.

- Emphasize your ability to think critically and find innovative solutions to challenges.

5. Prepare Questions for the Interviewer

Asking thoughtful questions during the interview shows your engagement and interest in the position. Prepare a few relevant questions that demonstrate your understanding of the role and the company.

- Ask about the company’s growth plans or industry trends that may impact the role of a Buncher.

- Inquire about opportunities for professional development or training within the organization.

Next Step:

Now that you’re armed with the knowledge of Buncher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Buncher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini