Are you gearing up for an interview for a Chute Builder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Chute Builder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

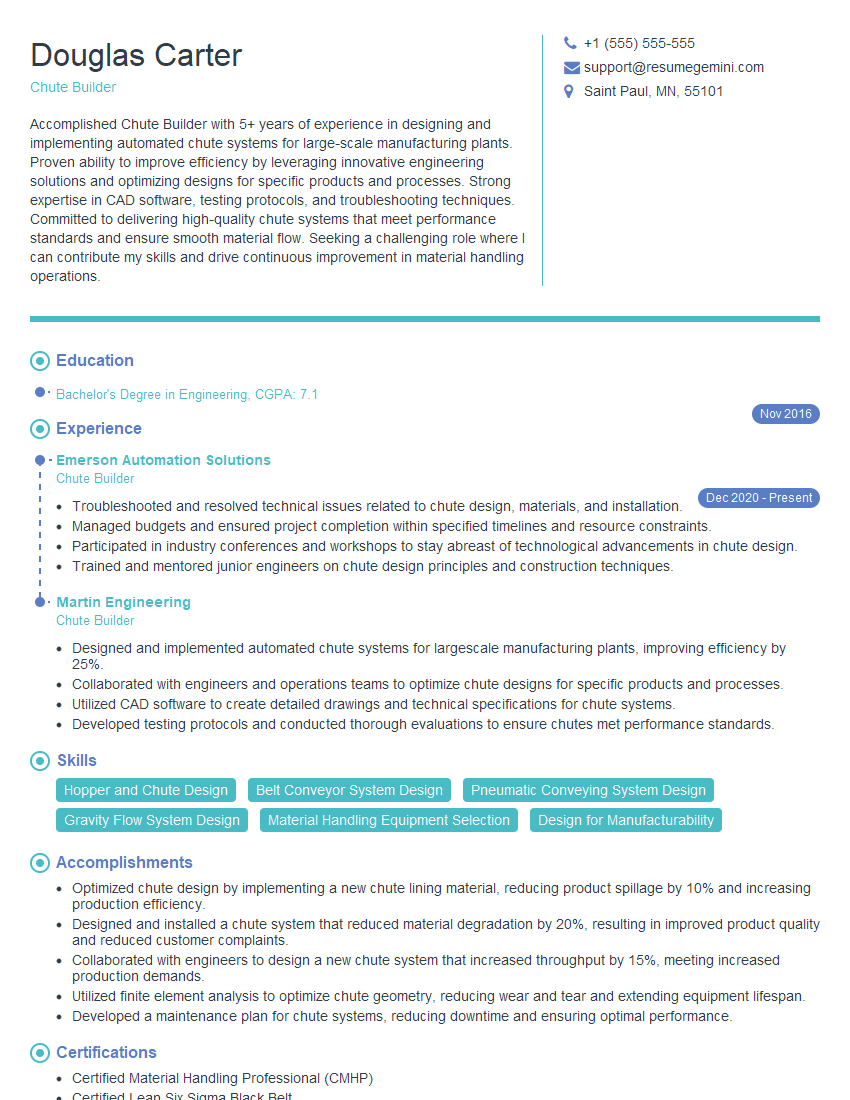

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chute Builder

1. Describe the process of designing a chute system for a bulk material handling application.

- Analyze the material properties and flow characteristics.

- Determine the required throughput and conveying distance.

- Select the appropriate chute geometry and materials based on material behavior, flow rate, and wear resistance.

- Design the chute to minimize flow resistance, prevent material buildup, and ensure smooth material flow.

- Incorporate features such as flow conditioners, impact plates, and wear liners to optimize performance and durability.

2. What are the key considerations for selecting materials for chute construction?

Durability and Wear Resistance

- Abrasion resistance to withstand the abrasive nature of the material being conveyed.

- Impact resistance to handle the impact of falling material.

- Corrosion resistance to prevent deterioration in harsh environments.

Material Flow and Friction

- Low friction coefficients to promote smooth material flow.

- Non-sticking properties to prevent material buildup.

3. Explain the different types of flow regimes in chute design and how they impact chute performance.

- Mass flow: Material moves as a solid mass, with all particles moving at the same velocity; maximizes conveying efficiency.

- Plug flow: Material moves as a plug, with only the top layer flowing; prone to flow interruptions.

- Trickle flow: Material flows in a thin layer, with particles sliding over each other; requires steep chute angles and careful material selection.

4. How do you ensure the structural integrity of a chute system under dynamic loading?

- Analyze the loads and stresses on the chute structure using finite element analysis (FEA) or other engineering methods.

- Design the chute to meet applicable load codes and safety standards.

- Select materials with high strength and toughness to withstand the impact and vibration of material flow.

- Incorporate reinforcement elements, such as stiffeners and supports, to enhance structural stability.

5. Discuss the role of flow aids in chute design and how they can improve material flow performance.

- Flow conditioners: Insert plates or baffles that create turbulence and break up material clumps, promoting consistent flow.

- Impact plates: Absorb the impact of falling material, reducing wear and noise.

- Wear liners: Protect the chute surface from abrasion and wear, extending chute lifespan.

- Vibration systems: Apply vibrations to loosen material and prevent blockages.

6. What are the common challenges faced in chute design and how do you address them?

- Material flow interruptions: Identify the cause (e.g., material bridging, agglomeration) and implement flow aids or design modifications to prevent them.

- Wear and abrasion: Use wear-resistant materials, incorporate wear liners, and optimize material flow to minimize wear.

- Noise and vibration: Use vibration dampeners, sound-absorbing materials, and impact plates to reduce noise and vibration.

- Maintenance and inspection: Design for easy access to critical areas for cleaning, maintenance, and inspection.

7. How do you stay up-to-date with the latest trends and developments in chute design and technology?

- Attend industry conferences and workshops.

- Read technical journals and research papers.

- Collaborate with experts and manufacturers in the field.

- Engage in continuing education programs.

8. Describe a complex chute design project that you worked on and the challenges you faced.

- State the project requirements and objectives.

- Discuss the design challenges encountered, including material properties, flow rate, environmental conditions, and space constraints.

- Explain how you addressed these challenges through innovative design solutions and material selection.

- Highlight the successful implementation of the chute system and the benefits it provided.

9. How do you ensure that your chute designs meet safety and environmental regulations?

- Familiarize yourself with relevant codes and standards, such as OSHA, ASME, and ISO.

- Incorporate safety features into the design, such as guardrails, warning labels, and access platforms.

- Consider the environmental impact of the chute, including noise pollution, dust emissions, and material spillage.

- Design the chute to minimize these impacts and comply with environmental regulations.

10. What sets you apart from other chute builders in the industry?

- Highlight your unique skills, experience, and technical expertise.

- Emphasize your commitment to innovative design, customer satisfaction, and continuous improvement.

- Showcase any specialized knowledge or certifications that make you a valuable asset.

- Explain how your approach to chute design and construction sets you apart from the competition.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chute Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chute Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Chute Builder plays a crucial role in the manufacturing, installation, and maintenance of chute systems used in various industries such as mining, construction, and food processing.

1. Design and Fabrication

Chute Builders are responsible for designing and fabricating chutes according to client specifications and industry standards.

- Analyze client requirements and develop design concepts.

- Select and source materials based on application and performance criteria.

2. Installation and Commissioning

Once the chutes are fabricated, Chute Builders oversee their installation and commissioning.

- Supervise site preparation and coordinate with other contractors.

- Install chutes using specialized tools and equipment.

3. Maintenance and Repair

Chute Builders ensure that installed chutes operate smoothly and efficiently.

- Conduct regular inspections and maintenance to identify potential issues.

- Perform repairs and replacements as needed to maintain optimal performance.

4. Quality Control and Safety

Chute Builders prioritize quality and safety in all aspects of their work.

- Adhere to strict quality standards and industry regulations.

- Implement safety procedures and wear appropriate protective gear.

Interview Tips

Preparing for a Chute Builder interview requires a combination of technical knowledge and clear communication skills.

1. Research the Company

Familiarize yourself with the company’s history, products, and industry involvement. This knowledge will help you understand the company’s needs and how your skills align with them.

- Visit the company website and social media pages.

- Read industry news and articles related to the company.

2. Highlight Relevant Experience

Emphasize your experience in chute design, fabrication, installation, and maintenance. Quantify your accomplishments whenever possible.

- Describe projects you’ve worked on that demonstrate your technical expertise.

- Provide specific examples of how you’ve improved chute performance or resolved operational issues.

3. Demonstrate Problem-Solving Skills

Chute Builders often encounter challenges during installation or maintenance. Be prepared to discuss your problem-solving approach and how you handle unexpected situations.

- Provide examples of how you’ve identified and resolved problems with chute systems.

- Explain how you prioritize safety and efficiency in your decision-making process.

4. Prepare Industry-Specific Questions

Ask informed questions about the company’s chute design philosophy, current industry trends, and any specific challenges they’re facing. This shows your engagement and interest in the industry.

- Inquire about the company’s use of new materials or innovative design techniques.

- Ask about their experience in handling chute systems with unique specifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chute Builder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!