Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Log Turner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

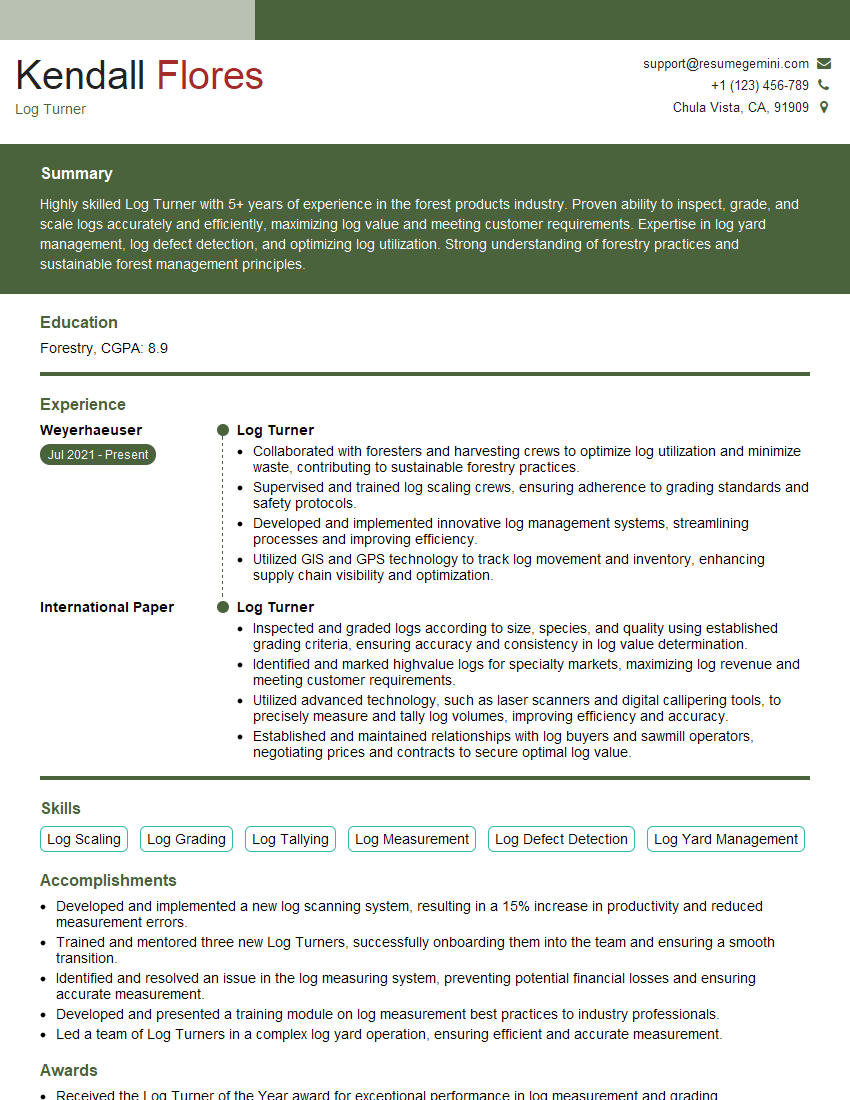

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Log Turner

1. Explain the process of grading logs?

Grading logs involves evaluating and classifying them based on specific quality criteria. Here’s a general overview of the process:

- Visual Inspection: Logs are visually examined for physical characteristics such as size, shape, defects, knots, and grain patterns.

- Length Measurement: Logs are measured for length using tapes or electronic devices to determine their overall length and merchantable length (the usable portion).

- Diameter Measurement: Diameters are measured at both ends of the log to determine average diameter and calculate volume.

- Defect Assessment: Logs are assessed for defects such as rot, decay, cracks, and insect damage, which affect their value.

- Species Identification: Logs are identified by their species based on their physical characteristics, such as bark texture, wood color, and grain patterns.

- Grade Determination: Based on the evaluation criteria, logs are assigned a grade that reflects their quality and market value.

2. What are the key factors that influence log grades?

Physical Characteristics

- Size (diameter and length)

- Shape (straightness, taper)

- Defects (knots, cracks, decay)

- Grain patterns

Species

- Wood quality (strength, durability)

- Market demand

- Specific end uses

3. How do you handle discrepancies in log grading between graders?

Discrepancies can arise due to varying interpretations or subjective assessments. To address this, I follow these steps:

- Communication: Discuss the discrepancies with the other grader to understand their reasoning.

- Re-inspection: Re-examine the log together to identify potential oversights or differences in observation.

- Grade Averaging: If the discrepancy persists, consider averaging the two grades to arrive at a fair assessment.

- Escalation: In cases of significant disagreement, consult with a supervisor or senior grader for guidance.

- Training: Provide additional training or clarification to improve consistency and reduce future discrepancies.

4. Describe the different types of log scaling methods and their applications.

- Diameter Tape Scaling: Measures log diameters at the small end, middle, and large end to calculate volume.

- Log Rule Scaling: Uses mathematical formulas and log tables to estimate volume based on diameter and length.

- Weight Scaling: Uses scales to measure log weight, which is then converted to volume using established density factors.

- Photo Scaling: Employs advanced technology to capture log images and calculate volume using computer programs.

5. How do you ensure accurate and reliable log measurements?

- Calibrated Equipment: Use well-calibrated tapes, scales, and measuring tools to ensure accurate measurements.

- Proper Technique: Follow standardized measurement techniques to minimize errors and ensure consistency.

- Training and Certification: Regularly train and certify log scalers to maintain their skills and knowledge.

- Verification and Auditing: Conduct regular verification checks and audits to ensure accuracy and adherence to standards.

- Collaboration: Engage with other scalers, log inspectors, and foresters to cross-check measurements and reduce discrepancies.

6. How do you adjust log grades and scaling to account for special requirements?

Special requirements may arise based on customer specifications or industry standards. To account for these:

- Grade Adjustments: Adjust log grades based on specific end uses, such as veneer production or structural lumber.

- Scaling Adjustments: Modify scaling methods to accommodate unique log shapes, lengths, or densities.

- Value-Added Features: Consider additional features, such as clear grain or special lengths, that may enhance the value of logs.

- Market Trends: Stay informed about market trends and customer preferences to adjust grades and scaling practices accordingly.

7. How do you handle customer complaints related to log grading and scaling?

- Listen Actively: Listen attentively to the customer’s concerns and gather all relevant information.

- Investigate Thoroughly: Examine the logs in question, review grading and scaling records, and consult with other relevant parties.

- Explain Rationale: Clearly explain the grading and scaling processes and provide evidence to support the assessment.

- Resolve Discrepancies: Address any discrepancies found during the investigation and negotiate a fair resolution with the customer.

- Maintain Professionalism: Maintain a professional and respectful demeanor throughout the process, even in challenging situations.

8. How do you stay up-to-date with the latest industry best practices and technological advancements?

- Industry Events: Attend conferences, workshops, and trade shows related to log grading and scaling.

- Continuing Education: Participate in certification programs and online courses to enhance knowledge and skills.

- Research and Publications: Read industry publications, research papers, and technical manuals to stay informed about advancements.

- Consultation with Experts: Seek guidance from experienced professionals and subject matter experts in the field.

- Technology Adoption: Stay abreast of emerging technologies and evaluate their potential impact on log grading and scaling practices.

9. What are the safety precautions you take when grading and scaling logs?

- Personal Protective Equipment: Wear appropriate safety gear, including hard hat, safety glasses, and protective clothing.

- Log Handling Techniques: Use safe log handling methods to prevent injuries, such as using cant hooks or peavies.

- Environmental Awareness: Be aware of hazards such as uneven terrain, slippery surfaces, and potential wildlife encounters.

- First Aid and Emergency Response: Carry a first aid kit and be familiar with emergency response procedures.

- Regular Maintenance: Ensure equipment, such as scaling tapes and scales, is well-maintained and in good working condition.

10. How do you manage your time effectively when grading and scaling a large volume of logs?

- Prioritization: Identify and prioritize high-priority logs or orders to ensure timely delivery.

- Batch Processing: Group similar logs together to streamline the grading and scaling process.

- Efficient Equipment: Use automated or semi-automated equipment to increase efficiency and reduce time.

- Delegate Tasks: Assign tasks to assistants or team members to optimize workflow and meet deadlines.

- Continuous Improvement: Regularly evaluate processes to identify areas for improvement and enhance efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Log Turner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Log Turner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Log Turners play a crucial role in the sawmilling process. Their primary responsibility is to position logs on a saw carriage and secure them using clamps or chains. This precise positioning ensures that the logs are cut accurately and efficiently, resulting in high-quality lumber or other wood products.

1. Log Positioning and Clamping:

Log Turners carefully position logs on the saw carriage, ensuring proper alignment and orientation for optimal cutting results. They use a variety of equipment, such as cant hooks, peaveys, and hydraulic clamps, to securely lock the logs in place, preventing them from shifting or moving during the cutting process.

2. Supervising Sawing Operations:

They monitor the sawing process, ensuring that the logs are cut according to specifications. They communicate with sawyers to adjust cutting parameters, such as blade height, feed rate, and kerf width, to achieve desired product dimensions and quality.

3. Log Sorting and Grading:

Log Turners often assist in sorting and grading logs based on size, species, and quality. They may use scaling tools to measure log dimensions and determine their value. Their accurate assessment helps ensure that the best logs are used for higher-value products, optimizing the mill’s profitability.

4. Equipment Maintenance and Safety:

They perform routine maintenance and inspections on sawing equipment, including clamps, chains, and saw blades. They also adhere to strict safety protocols, using protective gear and following established procedures to prevent accidents.

Interview Tips

Preparing for a Log Turner interview requires a combination of technical knowledge and interpersonal skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry:

Familiarize yourself with the company’s website, industry trends, and recent developments in sawmilling technology. This shows the interviewer that you are genuinely interested in the role and the company’s operations.

2. Highlight Your Technical Skills:

Emphasize your expertise in log positioning, clamping, and sawing operations. Share examples of how you have used your skills to improve efficiency, reduce waste, and ensure product quality.

3. Demonstrate Your Teamwork Ability:

Sawmills are fast-paced environments that require teamwork. Highlight your ability to work collaboratively with sawyers, log sorters, and other mill personnel to achieve production goals.

4. Discuss Your Safety Consciousness:

Sawmills can be hazardous environments. Emphasize your commitment to safety by describing your experience with safety protocols, accident prevention measures, and the use of protective equipment.

Next Step:

Now that you’re armed with the knowledge of Log Turner interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Log Turner positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini