Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Timber Hand position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

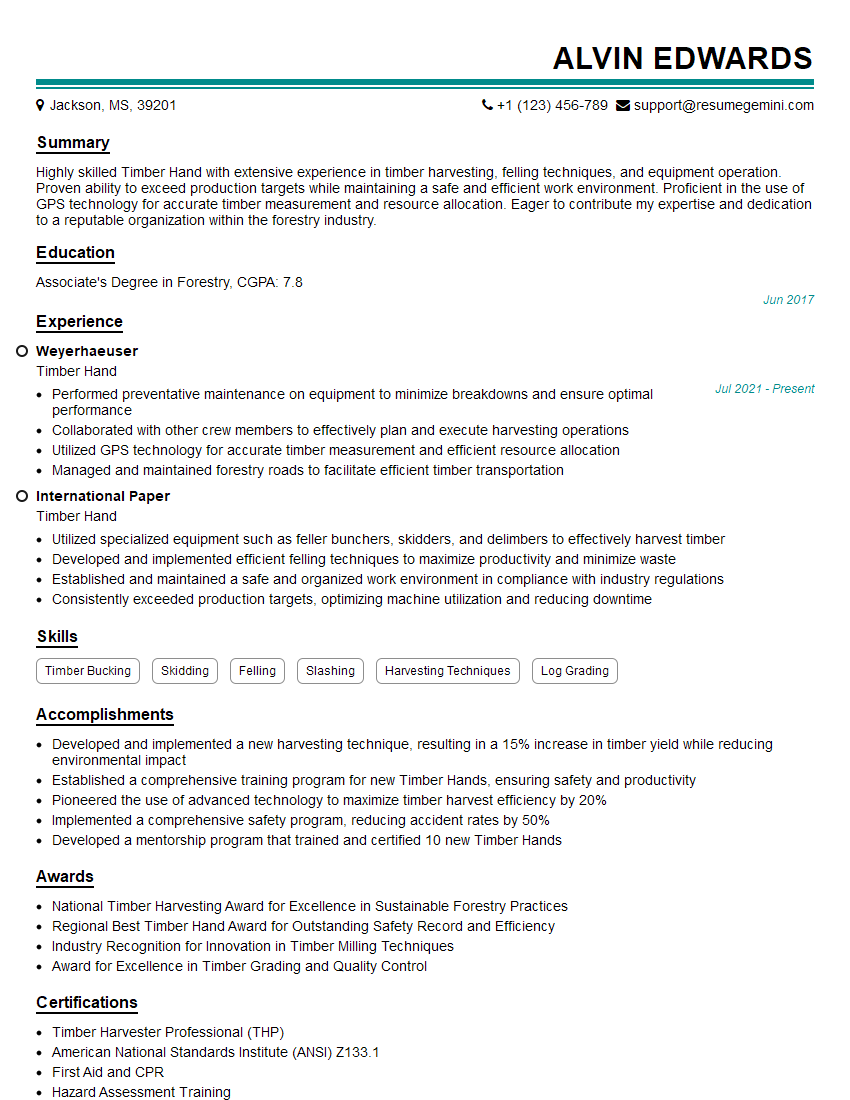

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Timber Hand

1. How do you determine the appropriate size and type of timber for a specific construction project?

When determining the appropriate size and type of timber for a construction project, several factors must be considered:

- Structural requirements: The size and strength of the timber must be sufficient to withstand the anticipated loads and stresses.

- Species and grade: Different timber species and grades have varying strength and durability characteristics.

- Environmental conditions: The timber must be suitable for the specific environmental conditions, such as moisture levels and exposure to insects or fungi.

- Cost and availability: The cost and availability of the timber must be taken into account.

2. What are the different methods used to join timber members, and when is each method most appropriate?

Common timber joining methods include:

Mechanical fasteners:

- Nails: Simple and economical for light-duty applications.

- Screws: Stronger and more versatile than nails, suitable for various loads.

- Bolts: Used for heavy-duty connections, provide high strength and rigidity.

Adhesives:

- Structural adhesives: High-strength adhesives used for permanent bonding.

- Carpenters glue: Used for non-structural applications, such as gluing together small pieces.

Joints:

- Mortise and tenon: Strong and durable joint for perpendicular members.

- Dovetail: Interlocking joint providing exceptional strength and stability.

- Scarf joint: Used to extend the length of a timber member.

3. How do you calculate the deflection of a timber beam under a given load?

Deflection of a timber beam can be calculated using the following formula:

Deflection = (Load x Length^3) / (48 x Modulus of Elasticity x Moment of Inertia)

- Load: Force applied to the beam.

- Length: Distance between supports.

- Modulus of Elasticity: Measure of the beam’s stiffness.

- Moment of Inertia: Measure of the beam’s resistance to bending.

4. What are the factors that affect the durability of timber, and how can they be mitigated?

Factors affecting timber durability:

- Moisture: High moisture levels promote decay and rot.

- Insects and fungi: Organisms that feed on timber, causing damage and weakening.

- Fire: Timber is flammable and can be easily damaged by fire.

Mitigation measures:

- Use moisture-resistant timber species or apply preservatives.

- Control moisture levels by providing adequate ventilation and drainage.

- Use insect and fungal repellents or sealants.

- Apply fire retardants or use non-flammable materials near potential fire hazards.

5. How do you identify and assess defects in timber members?

Defects in timber can be identified through visual inspection:

- Knots: Round or oval imperfections caused by branches.

- Cracks: Splits in the timber due to drying or stress.

- Warps: Deformations in the timber, such as bowing or twisting.

- Decay: Soft, discolored areas caused by fungal growth.

Assessment of defects involves determining their size, location, and potential impact on the structural integrity of the timber.

6. How do you ensure the quality of timber used in construction projects?

Quality control of timber involves:

- Sourcing: Selecting timber from reputable suppliers with a track record of providing high-quality materials.

- Inspection: Visually inspecting the timber for defects and ensuring it meets specifications.

- Testing: Conducting tests to verify the timber’s strength, durability, and other properties.

- Documentation: Maintaining records of inspections, tests, and any treatments applied to the timber.

7. What are the latest advancements in timber technology, and how are they being used in the construction industry?

Advancements in timber technology include:

- Engineered timber products: Products such as laminated veneer lumber (LVL) and cross-laminated timber (CLT) provide enhanced strength and stability.

- Timber preservatives: Advanced preservatives protect timber from decay, insects, and fire.

- Automated fabrication: Computer-controlled machines can precisely cut and shape timber components.

- Sustainable timber sourcing: Certification systems ensure that timber is harvested sustainably, promoting environmental conservation.

8. How do you stay up-to-date with the latest regulations and codes related to timber construction?

To stay up-to-date with regulations and codes:

- Read industry publications: Trade magazines and journals provide information on updates and changes to codes.

- Attend conferences and workshops: Industry events offer opportunities to learn about new regulations and best practices.

- Network with industry professionals: Connect with engineers, architects, and other professionals to exchange knowledge.

- Use online resources: Government websites and industry organizations provide access to current codes and regulations.

9. What are the ethical considerations related to timber harvesting and use, and how do you ensure responsible practices?

Ethical considerations in timber harvesting and use include:

- Environmental sustainability: Ensuring that timber is harvested from responsibly managed forests.

- Social responsibility: Considering the impact of timber harvesting on local communities and indigenous peoples.

- Economic viability: Balancing economic benefits with environmental and social concerns.

Responsible practices include:

- Sourcing certified timber: Choosing timber from forests certified by organizations like the Forest Stewardship Council (FSC).

- Implementing sustainable harvesting techniques: Minimizing environmental impact and promoting forest regeneration.

- Promoting reforestation and afforestation: Planting new trees to replace those harvested.

10. How do you manage and dispose of timber waste generated during construction projects?

Timber waste management involves:

- Waste reduction: Implementing measures to minimize waste generation, such as optimized cutting and reuse of materials.

- Recycling: Separating and recycling waste timber to recover materials and reduce landfill contributions.

- Energy recovery: Using waste timber as a source of energy through processes like biomass combustion.

- Responsible disposal: Disposing of waste timber in accordance with local regulations and environmental guidelines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Timber Hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Timber Hand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Timber Hands are responsible for the safe and efficient movement of timber and other materials in a sawmill or lumberyard.

1. Timber Handling

Lift, move, and stack timber using a variety of equipment, including forklifts, cranes, and conveyors.

- Ensure that timber is handled and stored properly to prevent damage or injury.

- Use slings and other equipment to secure timber during transport.

2. Equipment Operation

Operate and maintain a variety of equipment used in timber handling, including forklifts, cranes, and conveyors.

- Inspect equipment before use to ensure that it is in good working order.

- Perform basic maintenance and repairs on equipment as needed.

3. Safety and Compliance

Follow all safety regulations and procedures when handling timber and operating equipment.

- Wear appropriate personal protective equipment (PPE), such as hard hats, safety glasses, and gloves.

- Report any accidents or injuries to the supervisor immediately.

4. Teamwork and Communication

Work as part of a team to efficiently move timber and other materials.

- Communicate effectively with other team members and supervisors.

- Follow instructions and directions from supervisors.

Interview Tips

Preparing for a Timber Hand interview can help you make a good impression and increase your chances of getting the job. The following are some tips to help you prepare:

1. Research the Company and Position

Before the interview, take some time to learn about the company and the specific Timber Hand position you are applying for. This will help you answer questions about the company and its culture, as well as demonstrate your interest in the position.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

3. Be Prepared to Talk About Your Experience

The interviewer will likely want to know about your experience in timber handling and operating equipment. Be prepared to discuss your skills and experience in detail, and provide specific examples of your work.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the job and that you respect their time.

5. Be Yourself and Be Confident

The most important thing is to be yourself and be confident in your abilities. The interviewer will be able to tell if you are not being genuine, so it is important to relax and let your personality shine through.

Next Step:

Now that you’re armed with the knowledge of Timber Hand interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Timber Hand positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini