Are you gearing up for an interview for a Commerical Sheet Metal Foreman position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Commerical Sheet Metal Foreman and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

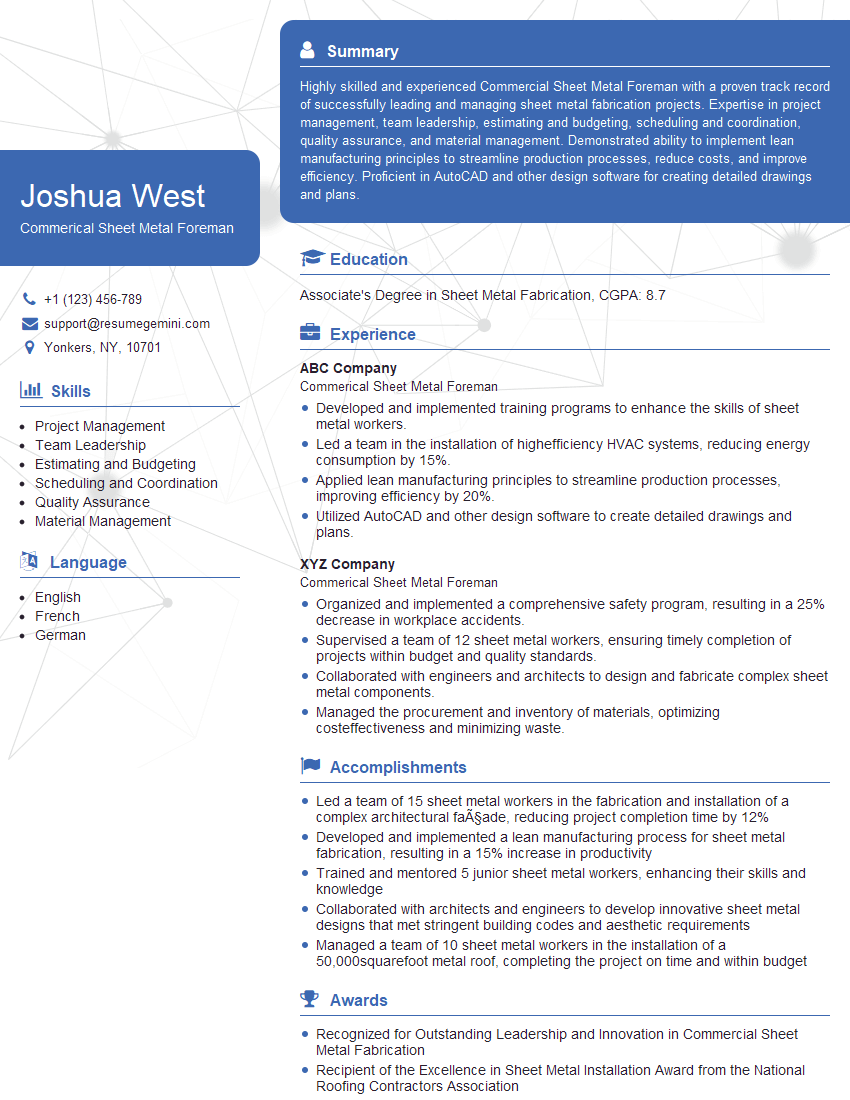

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Commerical Sheet Metal Foreman

1. Describe the different types of sheet metal fabrication techniques?

As a Commercial Sheet Metal Foreman, I have extensive experience in various sheet metal fabrication techniques, including:

- Shear cutting: Using a guillotine or power shear to cut straight lines in sheet metal.

- Brake forming: Bending sheet metal to create angles and shapes using a brake press.

- Roll forming: Passing sheet metal through a series of rollers to form it into continuous shapes, such as tubes or channels.

- Punching: Using a punch press to create holes or cutouts in sheet metal.

- Welding: Joining pieces of sheet metal together using various techniques such as MIG, TIG, or spot welding.

2. What are the key considerations when selecting the right sheet metal for a particular application?

Material Properties

- Thickness: Determines the strength and rigidity of the sheet metal.

- Tensile strength: Resistance to stretching or breaking under tension.

- Yield strength: Resistance to permanent deformation under stress.

- Corrosion resistance: Ability to withstand rust or other forms of corrosion.

Project Requirements

- Application: Intended use of the sheet metal, such as roofing, siding, or HVAC ductwork.

- Environment: Conditions the sheet metal will be exposed to, such as temperature, moisture, or chemicals.

- Cost: Balancing material properties with project budget.

3. Explain the importance of quality control in sheet metal fabrication?

- Ensures product meets customer specifications: Verifies that the finished product meets the required dimensions, tolerances, and finish.

- Minimizes production defects: Identifies and corrects potential errors early in the fabrication process, reducing scrap and rework.

- Maintains customer satisfaction: Provides confidence that the product will perform as expected and meet the intended application.

- Complies with industry standards: Adheres to established quality standards and regulations, ensuring safety and reliability.

4. Describe your experience in managing a team of sheet metal workers?

- Team leadership: Providing clear instructions, setting goals, and motivating team members.

- Communication and coordination: Ensuring effective communication between team members and other departments.

- Training and development: Identifying training needs and providing opportunities for skill enhancement.

- Performance management: Setting performance expectations, providing feedback, and recognizing achievements.

- Safety and compliance: Maintaining a safe work environment and adhering to safety regulations.

5. Explain the importance of staying up-to-date with the latest advances in sheet metal fabrication technology?

- Increased efficiency: Incorporating new technologies can streamline processes and improve productivity.

- Enhanced quality: Advanced equipment and techniques can produce higher quality products with greater precision.

- Cost savings: Automation and innovative methods can reduce production costs and minimize waste.

- Competitive advantage: Staying ahead in technology provides a competitive edge in the industry.

- Customer satisfaction: Meeting or exceeding customer expectations through the use of advanced fabrication techniques.

6. What are the common challenges you have faced as a Commercial Sheet Metal Foreman and how did you overcome them?

- Material shortages: Proactively sourcing alternative suppliers and exploring alternative materials to minimize project delays.

- Tight deadlines: Prioritizing tasks, optimizing workflow, and coordinating with other departments to meet project timelines.

- Technical difficulties: Collaborating with engineers and technicians to identify and resolve complex fabrication issues.

- Team conflicts: Addressing conflicts through open communication, mediation, and fair decision-making.

- Safety concerns: Implementing strict safety protocols, providing proper training, and fostering a safety-conscious work environment.

7. How do you ensure that your team follows safety regulations and maintains a safe work environment?

- Training and education: Providing comprehensive safety training and refresher courses to all team members.

- Regular safety inspections: Conducting periodic inspections to identify and mitigate potential hazards.

- Personal protective equipment: Enforcing the use of appropriate PPE, such as gloves, safety glasses, and hard hats.

- Emergency preparedness: Establishing clear emergency procedures and conducting drills to ensure team readiness.

- Incident reporting and investigation: Promptly investigating incidents and taking corrective actions to prevent recurrence.

8. Describe your experience in estimating material costs and labor hours for sheet metal fabrication projects?

- Material cost estimation: Using industry databases, vendor quotes, and historical data to calculate material requirements and costs.

- Labor hour estimation: Analyzing project drawings, identifying fabrication processes, and applying industry benchmarks to estimate labor hours.

- Overhead cost calculation: Factoring in overhead expenses, such as equipment depreciation, utilities, and administration, into the overall cost estimate.

- Variance analysis: Comparing actual costs to estimated costs and identifying areas for cost optimization.

- Customer communication: Clearly presenting cost estimates to customers and explaining the factors considered.

9. How do you stay informed about the latest industry trends and best practices in sheet metal fabrication?

- Industry publications and websites: Reading trade magazines, attending conferences, and visiting industry websites.

- Networking: Participating in industry associations and connecting with professionals at trade shows and online forums.

- Manufacturer training and workshops: Attending training sessions offered by sheet metal equipment manufacturers.

- Research and development: Exploring new technologies, materials, and fabrication methods through research and experimentation.

- Collaboration with engineers and architects: Staying up-to-date on design trends and emerging architectural applications of sheet metal.

10. How do you handle customer complaints and ensure customer satisfaction?

- Active listening: Listening attentively to customer concerns and acknowledging their perspectives.

- Problem identification: Thoroughly investigating the issue to identify the root cause.

- Solution development: Collaborating with the team to develop effective solutions that meet customer expectations.

- Clear communication: Keeping customers informed throughout the process and providing timely updates.

- Follow-up: Ensuring the issue is fully resolved and following up to ensure customer satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Commerical Sheet Metal Foreman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Commerical Sheet Metal Foreman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Commercial Sheet Metal Foreman

A Commercial Sheet Metal Foreman is responsible for supervising and coordinating the activities of a team of sheet metal workers engaged in the fabrication and installation of sheet metal products in commercial buildings. Their key responsibilities include:

1. Project Management

Overseeing the planning, execution, and completion of sheet metal projects within specified timeframes and budgets.

- Developing and implementing project plans and schedules.

- Coordinating with architects, engineers, and other contractors.

2. Team Leadership

Supervising and mentoring a team of sheet metal workers, providing guidance and support.

- Assigning tasks, monitoring progress, and evaluating performance.

- Ensuring employee safety and adherence to company policies.

3. Technical Expertise

Possessing a thorough understanding of sheet metal fabrication and installation techniques.

- Interpreting blueprints and specifications.

- Selecting appropriate materials and equipment.

4. Quality Control

Ensuring the quality of sheet metal products and installations meet industry standards.

- Inspecting materials and workmanship.

- Conducting quality checks and tests.

5. Cost Management

Monitoring project costs and ensuring adherence to budgets.

- Estimating material and labor costs.

- Negotiating with suppliers and subcontractors.

Interview Preparation Tips for a Commercial Sheet Metal Foreman

To ace the interview for a Commercial Sheet Metal Foreman position, it is crucial to prepare thoroughly. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and projects. Research the specific requirements of the Foreman role.

2. Highlight Your Experience and Skills

Emphasize your relevant experience in sheet metal fabrication and installation, including projects you have managed and teams you have led.

- Quantify your accomplishments using specific metrics.

- Be prepared to discuss your technical expertise and proficiency in industry standards.

3. Demonstrate Leadership and Communication Abilities

Showcase your ability to motivate and lead a team, as well as your communication skills in dealing with clients, contractors, and engineers.

- Describe your approach to employee development and performance management.

- Provide examples of successful project collaborations and conflict resolution.

4. Prepare Questions

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions about the company’s culture, growth opportunities, and the specific challenges of the role.

- Consider asking about industry trends or innovative practices in sheet metal fabrication.

- Inquire about the company’s commitment to safety and quality.

5. Practice Your Answers

Rehearse your responses to common interview questions. This will help you articulate your experience and qualifications confidently.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

- Practice your answers out loud to improve your delivery and reduce nervousness.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Commerical Sheet Metal Foreman, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Commerical Sheet Metal Foreman positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.