Are you gearing up for an interview for a Drilling Superintendent position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Drilling Superintendent and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

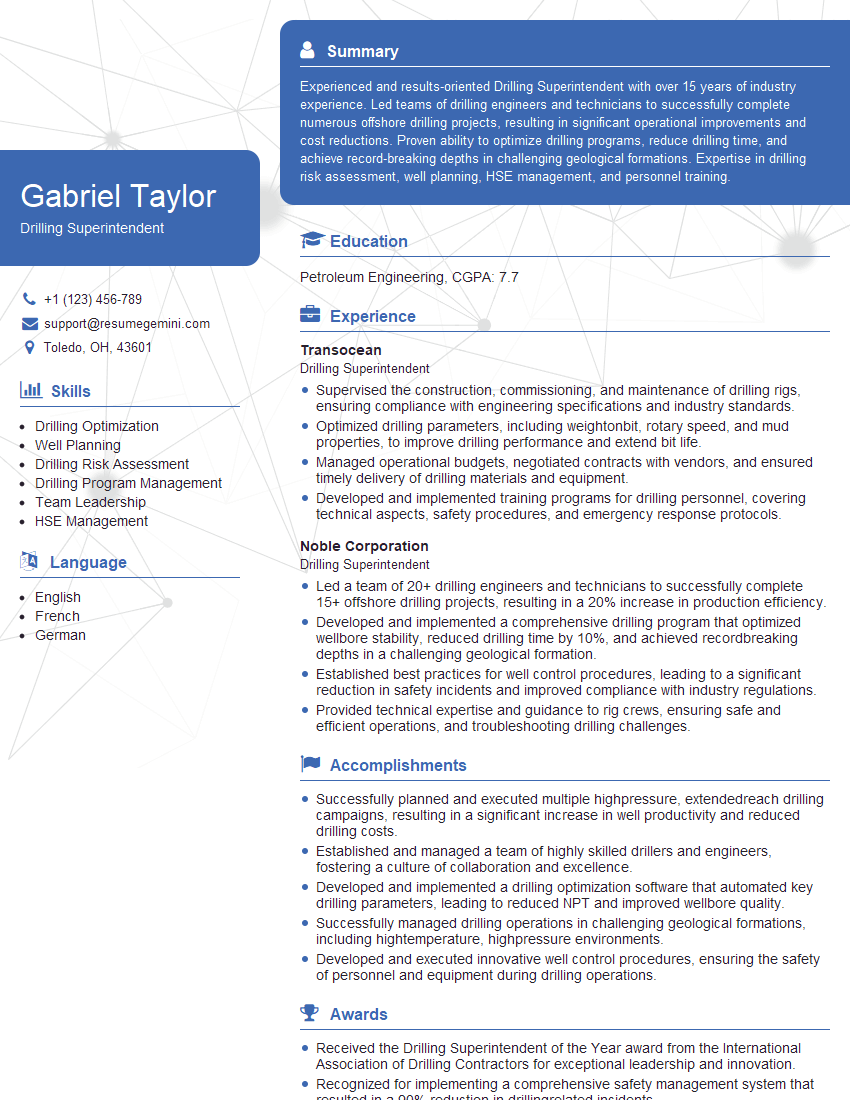

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drilling Superintendent

1. What are the key responsibilities of a Drilling Superintendent?

As a Drilling Superintendent, my key responsibilities include:

- Plan, organize, and direct all drilling and completion operations on assigned wells

- Supervise and lead a team of drilling engineers, rig crews, and support personnel

- Ensure that all drilling operations are conducted safely and efficiently

- Monitor drilling performance and make adjustments as needed to optimize production

- Work closely with other departments, such as geology, engineering, and production, to ensure that drilling operations are aligned with the overall project goals

2. What are the different types of drilling rigs and when are they used?

Onshore Drilling Rigs

- Truck-mounted rigs: These are small and mobile, making them ideal for drilling shallow wells in remote areas

- Skid-mounted rigs: These are larger and more powerful than truck-mounted rigs, and are used for drilling deeper wells in onshore areas

- Workover rigs: These are used for servicing and repairing existing wells

Offshore Drilling Rigs

- Jackup rigs: These are self-elevating rigs that are used for drilling in shallow water depths

- Semisubmersible rigs: These are mobile rigs that are used for drilling in deeper water depths

- Drill ships: These are large, floating rigs that are used for drilling in ultra-deep water depths

3. What are the key factors that affect drilling costs?

- Rig type and size

- Water depth

- Drilling depth

- Formation characteristics

- Drilling fluids

- Drilling equipment

- Labor costs

4. What are the different types of drilling fluids and what are their functions?

Water-Based Drilling Fluids

- Fresh water

- Salt water

- Polymer-based fluids

Oil-Based Drilling Fluids

- Diesel-based fluids

- Mineral oil-based fluids

- Synthetic oil-based fluids

Functions of Drilling Fluids

- Remove cuttings from the wellbore

- Control formation pressure

- Lubricate the drill bit and drill string

- Cool the drill bit and drill string

- Prevent corrosion of the drill bit and drill string

5. What are the different types of drilling bits and when are they used?

Roller Cone Bits

- Tricone bits: These are the most common type of roller cone bit, and are used for drilling in soft to medium-hard formations

- Steel tooth bits: These are used for drilling in hard formations

- Tungsten carbide insert bits: These are used for drilling in very hard formations

Fixed Cutter Bits

- Diamond bits: These are used for drilling in very hard formations, such as granite and basalt

- PDC bits: These are used for drilling in soft to medium-hard formations, and are more efficient than roller cone bits

6. What are the different types of well completions and when are they used?

Open Hole Completions

- Used when the formation is naturally fractured or has high permeability

- The wellbore is not lined with casing, and the formation fluids flow directly into the wellbore

Cased Hole Completions

- Used when the formation is not naturally fractured or has low permeability

- The wellbore is lined with casing, and the formation fluids flow into the wellbore through perforations in the casing

Types of Cased Hole Completions

- Single completion: The wellbore is completed with a single string of casing and a single production zone

- Multiple completion: The wellbore is completed with multiple strings of casing and multiple production zones

7. What are the different types of drilling rigs and what are their advantages and disadvantages?

Onshore Drilling Rigs

- Advantages: Mobile, can be used in remote areas, relatively low cost

- Disadvantages: Limited drilling depth, not suitable for offshore drilling

Offshore Drilling Rigs

- Advantages: Can drill in deep water, mobile, can be used in harsh environments

- Disadvantages: High cost, complex operations, not suitable for onshore drilling

8. What are the different types of drilling fluids and what are their functions?

Water-Based Drilling Fluids

- Functions: Remove cuttings from the wellbore, control formation pressure, lubricate the drill bit and drill string, cool the drill bit and drill string, prevent corrosion of the drill bit and drill string

Oil-Based Drilling Fluids

- Functions: Same as water-based drilling fluids, but also provide better lubrication and cooling, and are more resistant to contamination

9. What are the different types of drilling bits and what are their applications?

Roller Cone Bits

- Applications: Drilling in soft to medium-hard formations

Fixed Cutter Bits

- Applications: Drilling in hard to very hard formations

10. What are the different types of well completions and what are their advantages and disadvantages?

Open Hole Completions

- Advantages: Lower cost, less drilling time, greater production potential

- Disadvantages: Not suitable for all formations, can be difficult to repair

Cased Hole Completions

- Advantages: More versatile, can be used in all formations, easier to repair

- Disadvantages: Higher cost, more drilling time, lower production potential

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drilling Superintendent.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drilling Superintendent‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Planning and Supervision

Develops and implements drilling plans, ensuring alignment with project objectives and regulatory requirements.

- Supervises drilling operations, including rig setup, drilling, casing, and completion.

- Works closely with geological and engineering teams to optimize drilling performance.

2. Safety Management

Establishes and maintains a comprehensive safety program for drilling operations.

- Conducts regular safety inspections and audits to ensure compliance with industry standards.

- Investigates incidents and accidents, implementing corrective actions to prevent recurrence.

3. Cost Control and Optimization

Manages drilling budgets, identifying opportunities for cost optimization.

- Evaluates drilling equipment and services, negotiating contracts to ensure cost-effectiveness.

- Optimizes drilling parameters and techniques to reduce drilling time and costs.

4. Environmental Protection

Ensures compliance with environmental regulations and best practices during drilling operations.

- Develops and implements spill prevention and containment plans.

- Monitors drilling fluids and waste disposal, ensuring safe and responsible handling.

Interview Tips

To ace the interview for a Drilling Superintendent position, it’s crucial to prepare thoroughly. Here are some key tips:

1. Research the Company and Industry

Research the company’s drilling operations, projects, and safety record. Understand the industry trends and best practices.

2. Highlight your Experience and Skills

Emphasize your experience in drilling operations, safety management, cost control, and environmental protection.

3. Quantify your Accomplishments

Use specific examples to demonstrate your impact on project success. Quantify your accomplishments, such as reducing drilling costs or improving safety performance.

4. Prepare for Technical Questions

Expect technical questions about drilling equipment, drilling techniques, and safety regulations. Be prepared to discuss your knowledge and experience in detail.

5. Practice Behavioral Interviewing

Prepare for behavioral interview questions that focus on your problem-solving, decision-making, and teamwork skills.

6. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions about the company, the project, and the role. This shows your interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Drilling Superintendent interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.