Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pipeline Superintendent position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

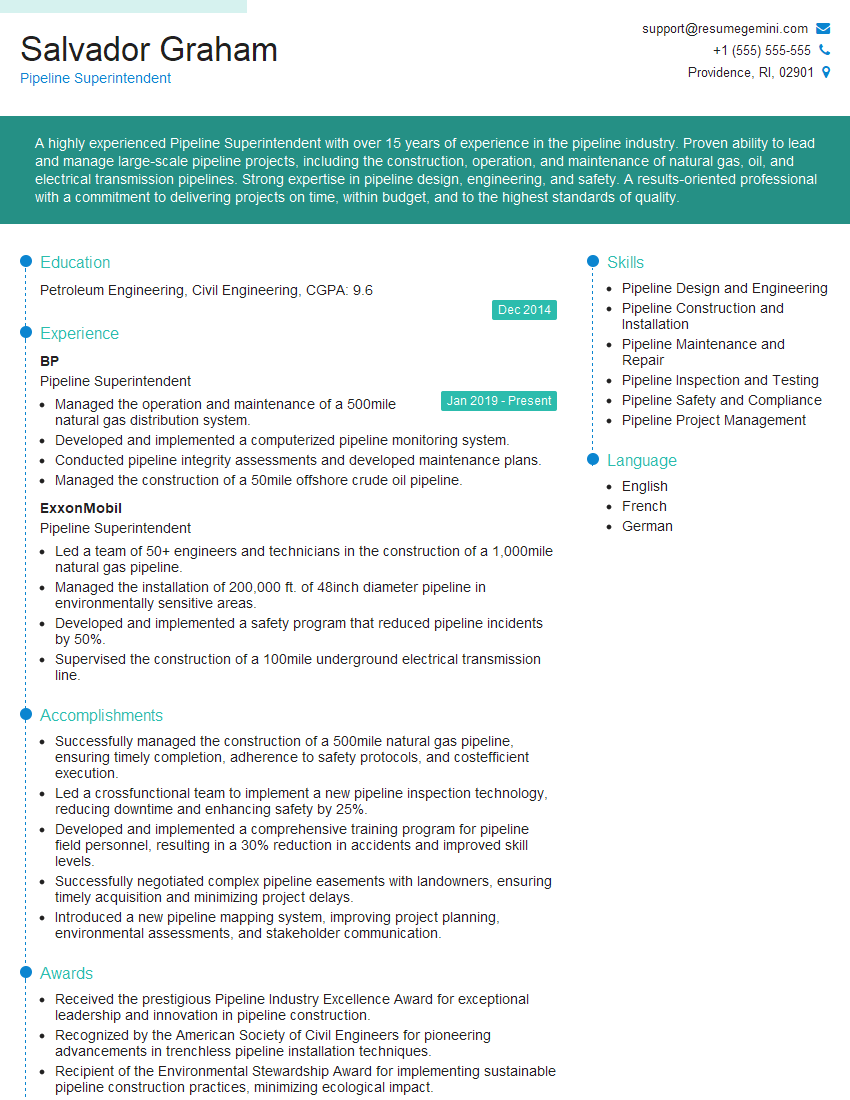

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipeline Superintendent

1. Explain the different types of pipeline construction techniques and when each one is typically used.

- Trenchless construction: Used for installing pipelines underground without excavating a trench, minimizing environmental impact and surface disruption.

- Open-cut construction: Traditional method involving excavating a trench, laying the pipeline, and backfilling the trench.

- Horizontal directional drilling (HDD): Used for installing pipelines beneath obstacles like rivers, roads, or buildings, reducing surface disturbance.

- Micro tunneling: Similar to HDD, but involves creating a smaller, guided tunnel using a remotely controlled machine.

- Direct pipe: Involves installing pipelines on the surface, typically used for large-diameter, low-pressure pipelines.

2. Describe the steps involved in planning and executing a pipeline maintenance program.

Risk assessment and inspection:

- Identify potential risks to the pipeline, such as corrosion, leaks, or damage.

- Conduct regular inspections using tools like smart pigs, leak detectors, and aerial surveys.

Maintenance activities:

- Repairs: Address leaks, corrosion, or damage promptly.

- Cleaning: Remove debris or sediment that can accumulate in the pipeline.

- Corrosion protection: Implement measures to prevent corrosion, such as coatings, cathodic protection, or inhibitors.

Monitoring and evaluation:

- Track maintenance activities and their effectiveness.

- Evaluate the overall condition of the pipeline and adjust the maintenance program as needed.

3. What are the key considerations when selecting materials for pipeline construction?

- Pipeline function: The specific purpose and operating conditions of the pipeline.

- Material properties: Strength, corrosion resistance, temperature tolerance, and pressure rating.

- Environmental factors: Soil conditions, temperature variations, and exposure to chemicals.

- Regulatory requirements: Adherence to industry standards and codes.

- Cost and availability: Balancing material costs with long-term durability and maintenance.

4. Discuss the safety precautions and emergency response procedures for pipeline operations.

Safety precautions:

- Proper training and certification of personnel.

- Adequate signage and warning systems.

- Regular safety inspections and audits.

- Implementation of safety protocols for construction, maintenance, and operations.

- Use of personal protective equipment.

Emergency response procedures:

- Immediate notification of authorities and stakeholders.

- Secure the area and evacuate personnel.

- Control and stop the flow of product.

- Implement containment measures to minimize environmental impact.

- Conduct a thorough investigation and implement corrective actions.

5. Explain the role of regulatory compliance in pipeline operations.

- Ensures safe and environmentally responsible pipeline operations.

- Protects public health and safety.

- Maintains pipeline integrity and reliability.

- Minimizes environmental impact and pollution.

- Provides a framework for pipeline design, construction, and maintenance.

- Compliance is monitored through inspections, audits, and reporting.

6. Describe the methods used to protect pipelines from corrosion.

- Coatings: Applying protective layers to the exterior of the pipe.

- Cathodic protection: Using an external current to prevent corrosion.

- Inhibitors: Adding chemicals to the pipeline fluid to reduce corrosion.

- Sacrificial anodes: Attaching less-reactive metals to the pipeline to corrode instead.

- Monitoring and inspection: Regularly checking the pipeline for signs of corrosion.

7. What are the key factors to consider when evaluating the performance of a pipeline?

- Flow rate: Volume of fluid transported through the pipeline.

- Pressure: Force exerted by the fluid on the pipeline walls.

- Pipeline integrity: Ability of the pipeline to withstand internal and external forces.

- Environmental impact: Effects of pipeline operations on the surrounding environment.

- Safety record: History of accidents, incidents, and near misses.

- Compliance: Adherence to regulatory requirements and industry standards.

8. Explain the principles behind pipeline hydraulics.

- Fluid flow: Properties of fluids and their movement through pipelines.

- Pressure drop: Decrease in pressure due to friction and other factors.

- Flow rate: Rate at which fluid moves through the pipeline.

- Pipe sizing: Determining the appropriate diameter for the pipeline based on flow requirements.

- Pumping systems: Selection and operation of pumps to maintain desired flow rates.

9. Discuss the environmental considerations in pipeline construction and operations.

- Habitat preservation: Minimizing impact on wildlife and vegetation.

- Erosion control: Preventing soil erosion during construction.

- Water quality protection: Avoiding contamination of water sources.

- Air pollution control: Reducing emissions from construction and operations.

- Waste management: Proper disposal of construction and operational waste.

10. Describe the role of technology in modern pipeline operations.

- Pipeline monitoring systems: Remotely monitoring pipeline conditions and detecting anomalies.

- Smart pigs: Intelligent inspection tools that provide real-time data on pipeline integrity.

- GPS tracking: Tracking the location and movements of pipeline assets.

- Advanced modeling and simulation: Optimizing pipeline design and operations.

- Remote operations and maintenance: Using technology to manage pipelines remotely.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipeline Superintendent.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipeline Superintendent‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities for a Pipeline Superintendent

A Pipeline Superintendent plays a pivotal role in the safe and efficient operation of a pipeline system. Their key responsibilities include:1. Pipeline Management and Inspection

Managing and overseeing the maintenance, inspection, and repair of pipelines to ensure their integrity and compliance with regulations.

- Conducting routine inspections to identify potential issues or damage.

- Supervising maintenance and repair crews to address identified issues promptly.

- Developing and implementing preventive maintenance plans to minimize downtime and extend pipeline life.

2. Construction Oversight

Overseeing the construction, installation, or expansion of pipelines, ensuring adherence to specifications and safety standards.

- Reviewing and approving pipeline construction plans.

- Inspecting ongoing construction activities to monitor progress and ensure compliance with designs.

- Collaborating with contractors to resolve any issues or delays during construction.

3. Safety and Compliance

Ensuring adherence to all applicable safety regulations and industry best practices related to pipeline operations.

- Implementing and enforcing safety protocols for pipeline maintenance and construction.

- Conducting regular safety audits and training programs for personnel.

- Maintaining proper recordkeeping and documentation of all safety-related activities.

4. Emergency Response

Leading and coordinating emergency response efforts in the event of pipeline incidents or leaks.

- Developing and implementing emergency response plans.

- Mobilizing and directing response teams to mitigate risks and minimize damage.

- Communicating with stakeholders and regulatory agencies during emergencies.

Interview Tips to Ace the Pipeline Superintendent Interview

To prepare for a successful interview for a Pipeline Superintendent position, consider the following tips:1. Research the Company and Industry

Thoroughly research the company you are applying to, their industry, and the specific pipeline system you will be responsible for.

- Learn about the company’s history, mission, and values.

- Understand the regulatory environment and safety standards applicable to the industry.

- Review articles or news about the company’s recent projects or initiatives.

2. Highlight Your Experience and Skills

Emphasize your relevant experience and skills that align with the key job responsibilities described above.

- Quantify your accomplishments whenever possible, using specific metrics or examples.

- If you have experience in other related fields, such as project management or regulatory compliance, highlight how those skills are transferable.

- Be prepared to discuss your understanding of pipeline construction techniques and safety protocols.

3. Showcase Your Leadership and Communication Skills

Interviewers will be interested in your ability to lead a team and effectively communicate with various stakeholders.

- Share examples of how you have successfully motivated and managed teams in the past.

- Demonstrate your ability to clearly convey technical information to both technical and non-technical audiences.

- Emphasize your experience in building and maintaining strong relationships with contractors and regulatory agencies.

4. Prepare for Technical Questions

Expect to be asked technical questions related to pipeline operations, construction, and safety.

- Review your knowledge of pipeline design, materials, and construction methods.

- Be familiar with common industry standards and regulations.

- Think through potential emergency scenarios and how you would respond.

5. Dress Professionally and Be Punctual

First impressions matter, so dress professionally and arrive on time for your interview.

- Wear a clean, pressed suit or business attire.

- Arrive early to show that you respect the interviewer’s time.

- Maintain good posture and make eye contact during the interview.

Next Step:

Now that you’re armed with the knowledge of Pipeline Superintendent interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pipeline Superintendent positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini