Are you gearing up for a career in Steel Pan Form Placing Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Steel Pan Form Placing Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

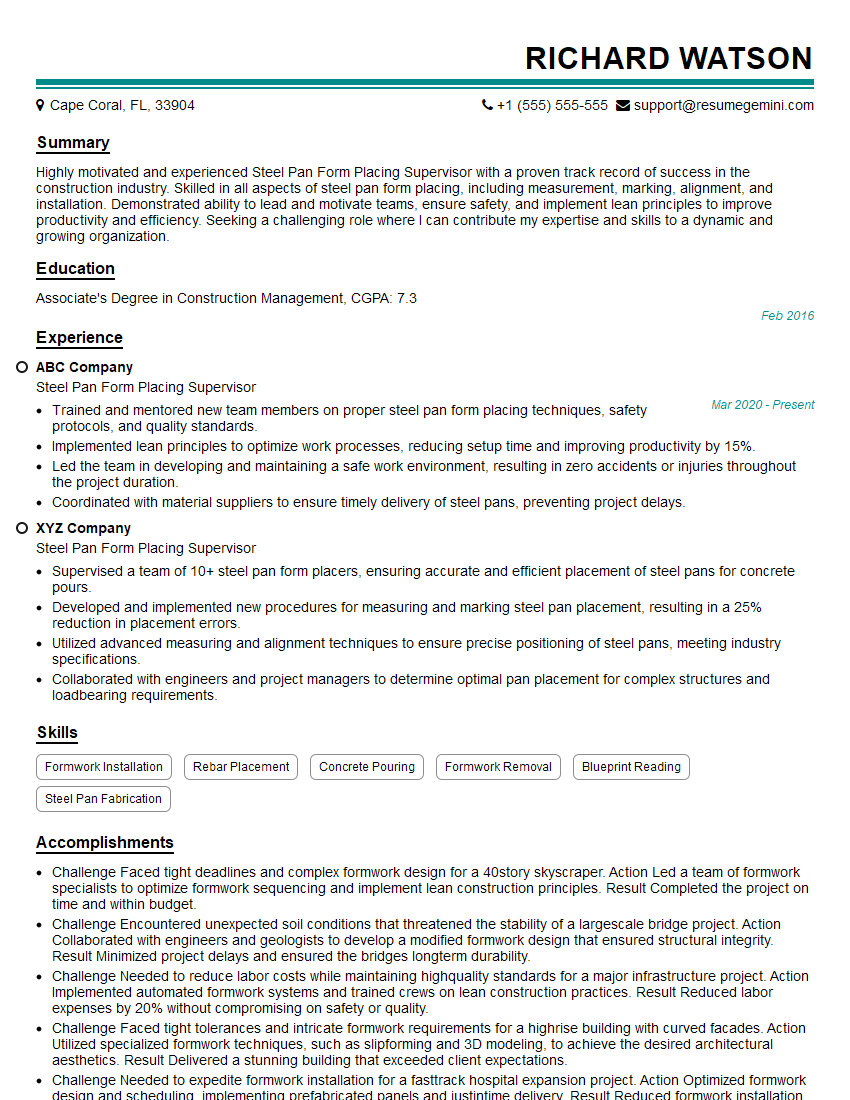

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Pan Form Placing Supervisor

1. What are the key responsibilities of a Steel Pan Form Placing Supervisor?

As a Steel Pan Form Placing Supervisor, my key responsibilities include:

- Supervising and coordinating the activities of form placing crews to ensure that all forms are placed accurately and according to specifications.

- Inspecting and approving the work of form placing crews to ensure that it meets quality standards.

- Developing and implementing training programs for form placing crews to improve their skills and productivity.

- Working closely with other supervisors and project managers to coordinate the work of form placing crews with other trades.

- Maintaining a safe work environment for form placing crews.

2. What are the different types of steel pans used in construction?

Cold-formed steel pans

- Made from cold-rolled steel sheets

- Lightweight and easy to handle

- Used for a variety of applications, including floor decks, roof decks, and wall panels

Hot-rolled steel pans

- Made from hot-rolled steel sheets

- Stronger and more durable than cold-formed steel pans

- Used for applications where strength is a priority, such as bridges and skyscrapers

Stainless steel pans

- Made from stainless steel

- Resistant to corrosion and chemicals

- Used for applications where hygiene is important, such as hospitals and food processing plants

3. What are the advantages of using steel pans for formwork?

- Steel pans are lightweight and easy to handle.

- Steel pans are strong and durable.

- Steel pans are reusable, which can save time and money.

- Steel pans are versatile and can be used for a variety of applications.

- Steel pans are fire-resistant.

4. What are the challenges of working with steel pans?

- Steel pans can be sharp and can cause cuts or lacerations.

- Steel pans can be heavy, which can make them difficult to handle.

- Steel pans can be slippery, which can make them difficult to grip.

- Steel pans can be noisy, which can make it difficult to communicate.

- Steel pans can be expensive to purchase and maintain.

5. What is the proper way to handle steel pans?

- Wear gloves when handling steel pans to prevent cuts or lacerations.

- Use a dolly or a cart to move heavy steel pans to avoid injuries.

- Be careful not to drop steel pans, as they can be damaged or cause injury.

- Store steel pans in a dry place to prevent rust.

6. What are the different types of formwork systems?

- Traditional formwork systems

- Modular formwork systems

- Slipform systems

- Tilt-up systems

- Precast systems

7. What are the factors to consider when choosing a formwork system?

- The type of structure being built

- The size and complexity of the structure

- The budget for the project

- The availability of skilled labor

- The safety requirements for the project

8. What are the benefits of using modular formwork systems?

- Modular formwork systems are versatile and can be used for a variety of applications

- Modular formwork systems are easy to assemble and disassemble, which can save time and money.

- Modular formwork systems are lightweight and easy to handle, which can reduce fatigue and injuries.

- Modular formwork systems are durable and can be reused multiple times, which can save money.

9. What are the challenges of working with modular formwork systems?

- Modular formwork systems can be more expensive to purchase than traditional formwork systems.

- Modular formwork systems can be more difficult to design and engineer than traditional formwork systems.

- Modular formwork systems can be more difficult to assemble and disassemble than traditional formwork systems.

10. What is your experience with formwork systems?

I have over 10 years of experience working with formwork systems. I have worked on a variety of projects, including high-rise buildings, bridges, and tunnels. I am familiar with all types of formwork systems, and I am proficient in the design, assembly, and disassembly of formwork systems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Pan Form Placing Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Pan Form Placing Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Steel Pan Form Placing Supervisor is responsible for overseeing and coordinating the placement of steel pans for concrete construction projects.

1. Planning and Preparation

Collaborate with engineers and project managers to develop and execute work plans for steel pan placement.

- Determine the appropriate size, shape, and quantity of steel pans required for each project.

- Establish timelines and schedules for pan placement, considering factors such as weather conditions and crew availability.

2. Materials Management

Manage the procurement and inventory of steel pans, ensuring their timely delivery to the construction site.

- Coordinate with suppliers to secure required materials and track their delivery status.

- Inspect steel pans upon delivery and ensure they meet specifications and safety standards.

3. Crew Supervision

Lead and supervise a team of workers responsible for placing steel pans.

- Provide clear instructions and guidance to crew members, ensuring proper pan placement techniques.

- Monitor crew progress, identify any challenges or delays, and implement corrective measures.

4. Quality Assurance

Ensure the quality and accuracy of steel pan placement, adhering to project specifications and industry standards.

- Inspect steel pan placement regularly and address any deviations or non-conformances promptly.

- Collaborate with quality control inspectors to verify the accuracy and integrity of the work.

5. Safety Compliance

Uphold safety standards and regulations throughout the steel pan placement process.

- Conduct safety briefings and ensure workers adhere to established safety protocols.

- Inspect equipment and work areas regularly to identify and address potential hazards.

Interview Tips

1. Research the Company and Position

Familiarize yourself with the construction company, its reputation, and the specific requirements of the Steel Pan Form Placing Supervisor position.

- Visit the company website, review industry publications, and connect with professionals in the field.

- Identify key responsibilities and qualifications listed in the job description and align your skills and experience accordingly.

2. Practice Answering Common Interview Questions

Prepare for common interview questions that may assess your technical skills, leadership abilities, and industry knowledge.

- Consider questions related to steel pan placement techniques, quality control procedures, and safety regulations.

- Craft well-structured answers that highlight your expertise and demonstrate your understanding of the role.

3. Showcase Your Leadership and Communication Skills

Emphasize your ability to effectively lead and motivate a team of workers.

- Provide examples of situations where you successfully managed a crew, resolved conflicts, and maintained a positive work environment.

- Highlight your communication skills, including your ability to convey instructions clearly, provide feedback, and collaborate effectively.

4. Prepare Questions for the Interviewer

Ask thoughtful questions that demonstrate your interest in the position and the company.

- Inquire about the company’s safety culture, quality standards, and professional development opportunities.

- Seek information about the project timelines, crew size, and anticipated challenges.

5. Dress Professionally and Arrive on Time

Make a positive first impression by dressing appropriately and arriving at the interview on time.

- Choose business-casual attire that conveys professionalism and respect for the company.

- Allow ample time for travel and parking to avoid any delays or last-minute stress.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Steel Pan Form Placing Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Steel Pan Form Placing Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.